What are JIC Hydraulic Fittings?

In the complex world of hydraulics, the choice of fittings can make or break an operation. That’s where JIC (Joint Industry Council) fittings come into play, the industry standard for hydraulic connections. Developed by the Joint Industry Council, the standard has become the first choice for professionals seeking reliability, ease of use and high performance. Understanding JIC fittings is not just a matter of technical knowledge, it’s also about making smart business decisions. These fittings offer a range of benefits from quick assembly to high-pressure capability, making them a cost-effective and versatile choice for a variety of applications. Whether you work with industrial machinery, automotive systems, aerospace or general hydraulics, JIC fittings offer unrivaled compatibility and interchangeability.

In this comprehensive guide, we’ll take an in-depth look at the origins of the JIC standard, its key features, and discuss what makes it stand out in the hydraulics industry.

Table of Contents

What does JIC Stand for?

JIC stands for Joint Industrial Council, an organization that seeks to standardize specifications for hydraulic fittings. By creating a common standard, the JIC makes it easier for professionals to select, install, and maintain hydraulic systems, thereby reducing downtime and increasing efficiency.

JIC standards are fundamental to quality and performance in the hydraulic industry, ensuring that fittings meet stringent requirements. This standardization allows professionals to focus more on the application at hand without worrying about the compatibility of various components.

Key Features of JIC Hydraulic Fittings

When it comes to hydraulic fittings, details matter, and JIC fittings have a number of features that make them the preferred choice of industry professionals. Let’s analyze each of these key features in turn.

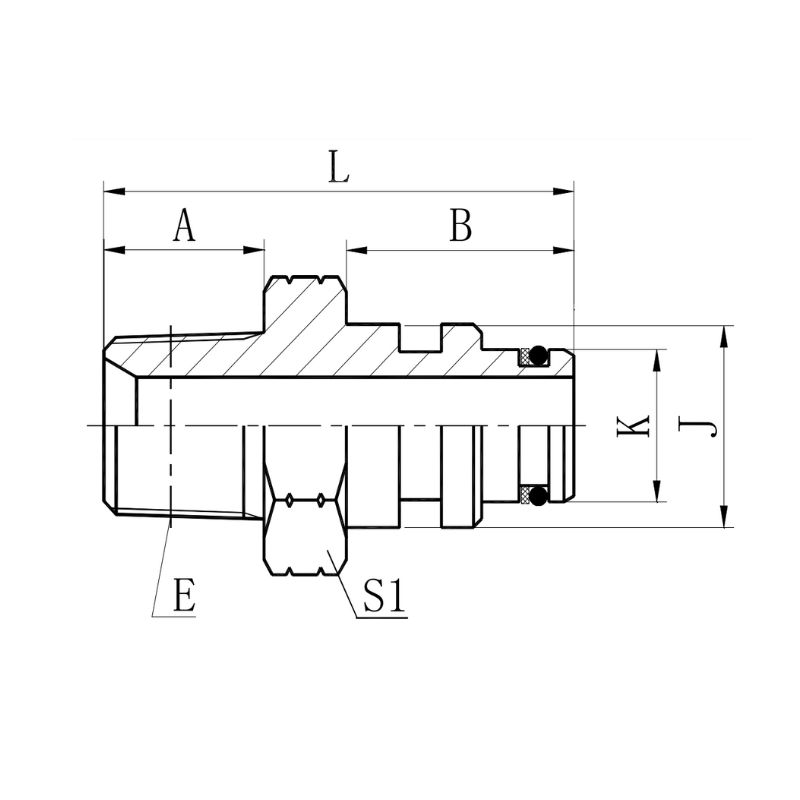

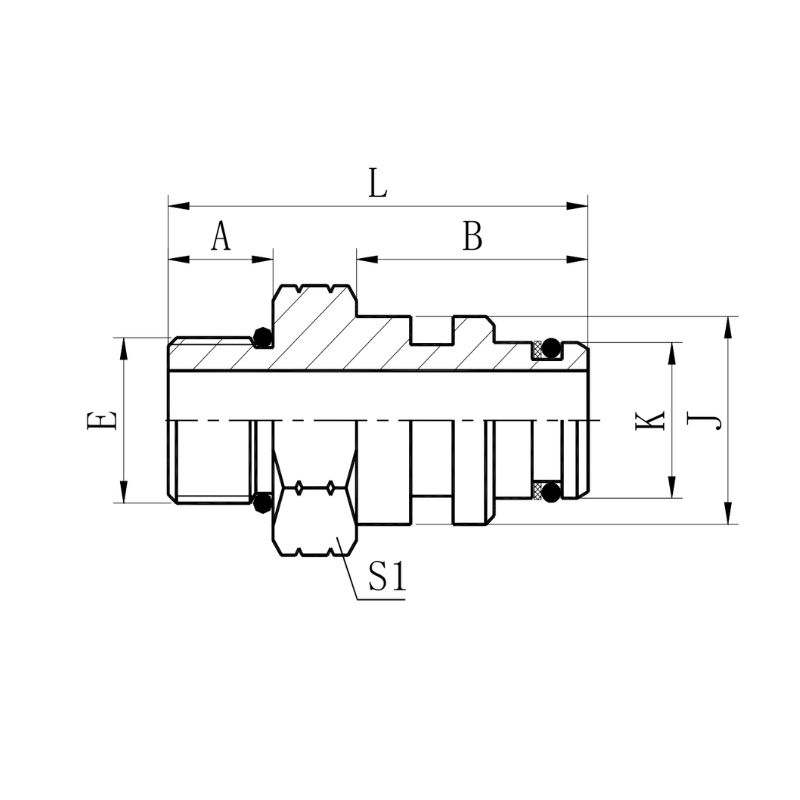

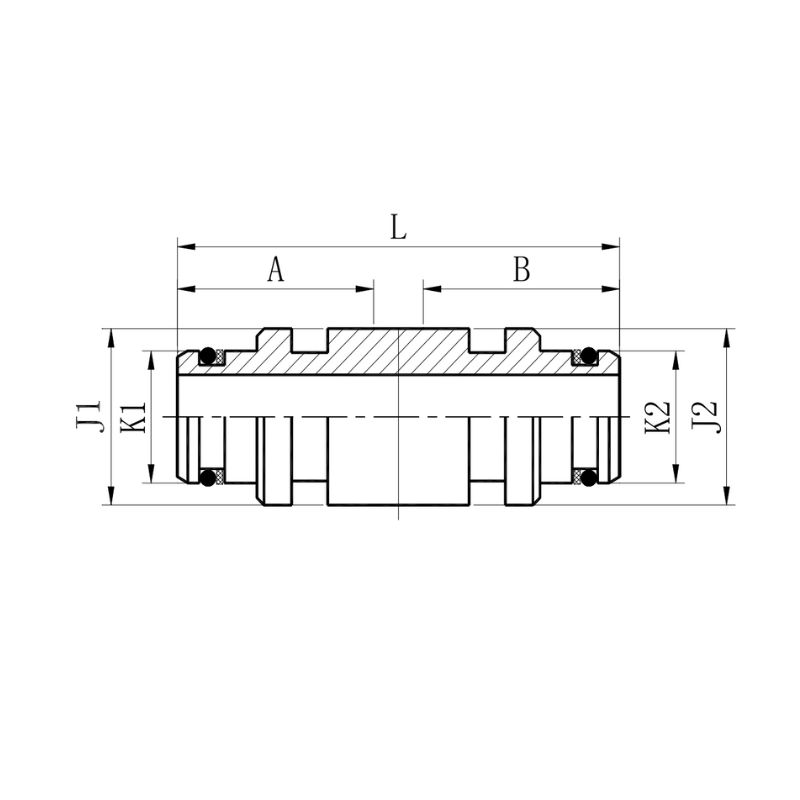

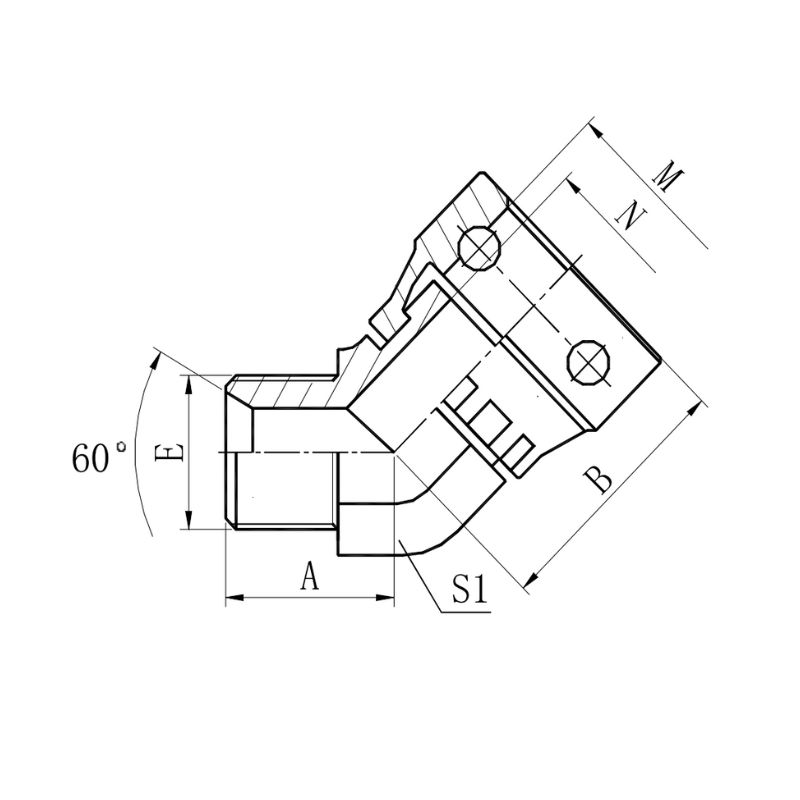

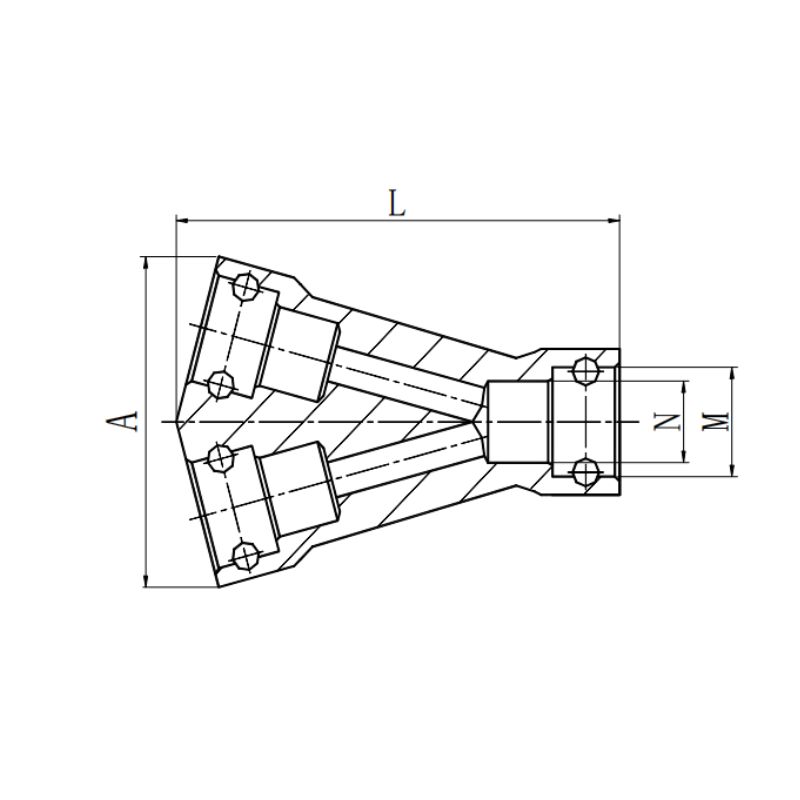

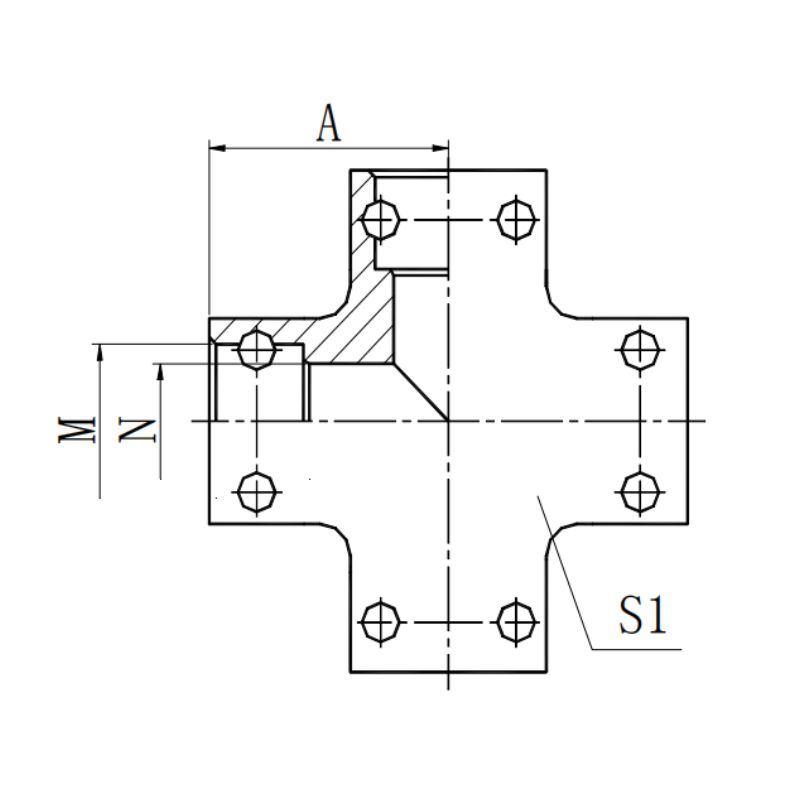

Standardized Dimensions

First, JIC fittings follow standardized dimensions. This standardization simplifies the selection process and ensures that you can easily find the fitting that meets your system requirements. Whether you’re dealing with a high-pressure application or a routine setup, you can rest easy knowing that the dimensions are standardized. You don’t have to sift through a myriad of options or worry about compatibility; standardized dimensions make it simple.

Material Selection

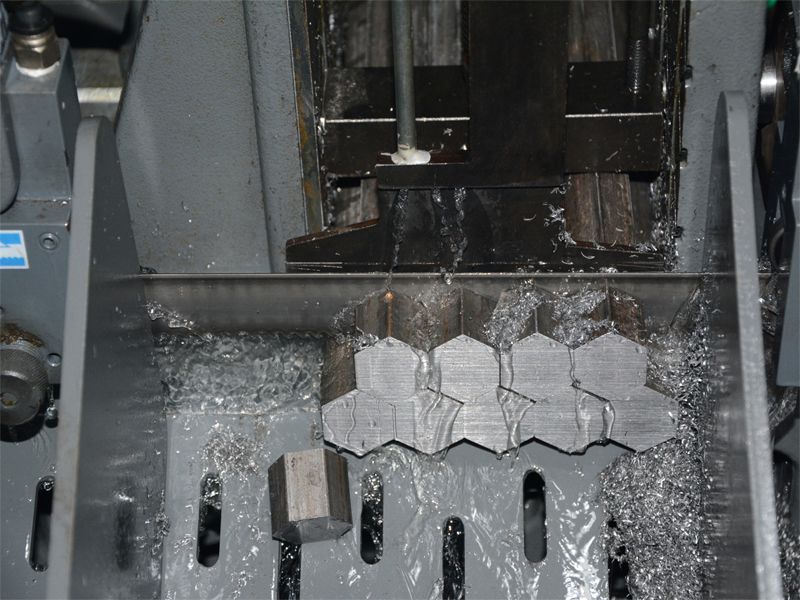

Material selection is another key factor; JIC fittings are typically made of high-quality steel, but stainless steel and brass options are also available. The material you choose will depend on your specific application. For example, if you work in a corrosive environment, stainless steel is a better choice. The point is, that JIC fittings are available in a range of materials to meet a variety of needs without sacrificing quality.

Pressure Ratings

Understanding the pressure rating of JIC fittings is critical. These fittings can withstand a wide range of pressures, making them suitable for both low and high-pressure applications. Fittings are typically labeled with the pressure rating for easy identification and to ensure that the fitting you select will meet the pressure requirements of your system.

Fitting Size | Dash Size | Thread Size | Torque ft/lbs |

JIC2 | -02 | 5/16-24 | 6-7 |

JIC3 | -03 | 3/8-24 | 6-9 |

JIC4 | -04 | 7/16-20 | 9-12 |

JIC5 | -05 | 1/2-20 | 14-15 |

JIC6 | -06 | 9/16-18 | 18-20 |

JIC8 | -08 | 3/4-16 | 27-39 |

JIC10 | -10 | 7/8-14 | 36-63 |

JIC12 | -12 | 1 1/16-12 | 65-88 |

JIC14 | -14 | 1 3/16-12 | 75-103 |

JIC16 | -16 | 1 5/16-12 | 85-113 |

JIC20 | -20 | 1 5/8-12 | 115-133 |

JIC24 | -24 | 1 7/8-12 | 125-167 |

JIC32 | -32 | 1 1/2/-12 | 190-258 |

Advantages of Using JIC Fittings

JIC fittings offer many advantages that make them the preferred choice of professionals in the hydraulic industry. Let’s take a closer look at these benefits and see why JIC fittings are often considered the gold standard.

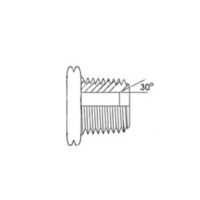

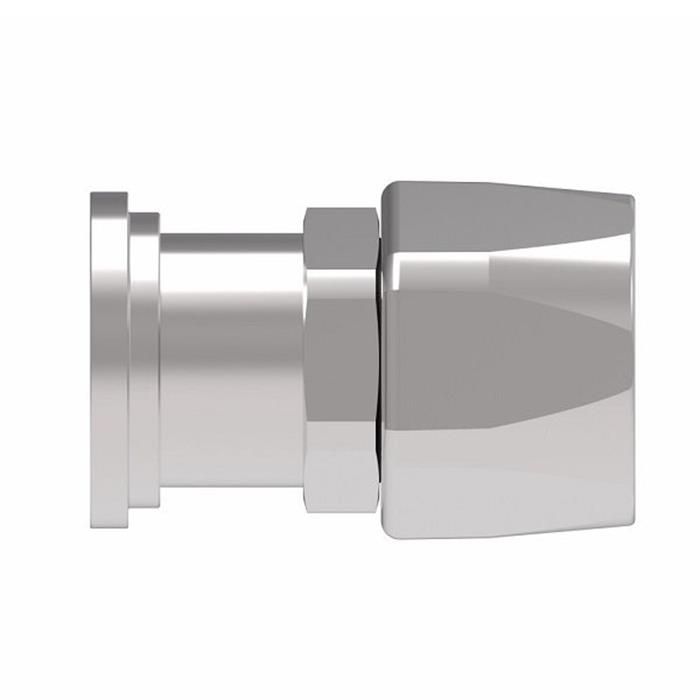

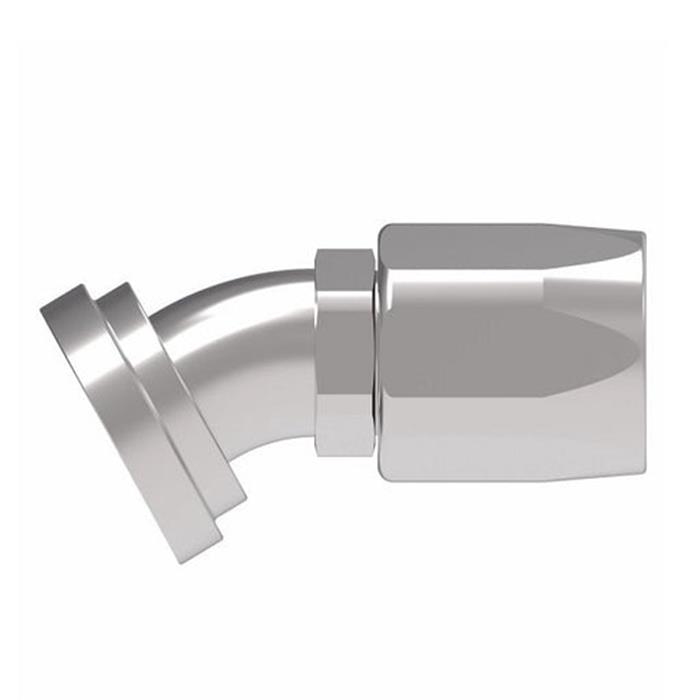

Metal to metal

The 37-degree flared seating surface of the JIC fitting creates an efficient metal-to-metal seal that is both strong and reliable. This design withstands high pressures and extreme conditions, making it ideal for a variety of industrial applications. The elimination of additional sealants means less risk of contamination of the hydraulic system, which is especially important in sensitive applications such as aerospace, medical equipment and food processing.

Easy Assembly

One of the most significant benefits of JIC fittings is their ease of assembly. Standardized sizes and thread types mean you can quickly and safely connect components without specialized tools.

Cost Effective

JIC fittings offer an excellent balance between cost and performance. Their durability means fewer replacements over time, while their ease of assembly reduces labor costs. Taking these factors into account, JIC fittings clearly offer a high return on investment.

High-Pressure Applications

JIC fittings excel in high-pressure environments. Their rugged construction and quality materials allow them to withstand extreme pressures without failure. Whether you’re in aerospace or industrial machinery, you can count on JIC fittings to perform under pressure.

Compatibility and Interchangeability

Perhaps one of the most underrated advantages of JIC fittings is their compatibility with other systems. Standard sizes and thread types make JIC fittings interchangeable with other standardized fittings, providing flexibility.

Common Applications

The versatility of JIC fittings makes them suitable for a wide range of applications. Let’s take a look at how these fittings are used in some key industries and systems.

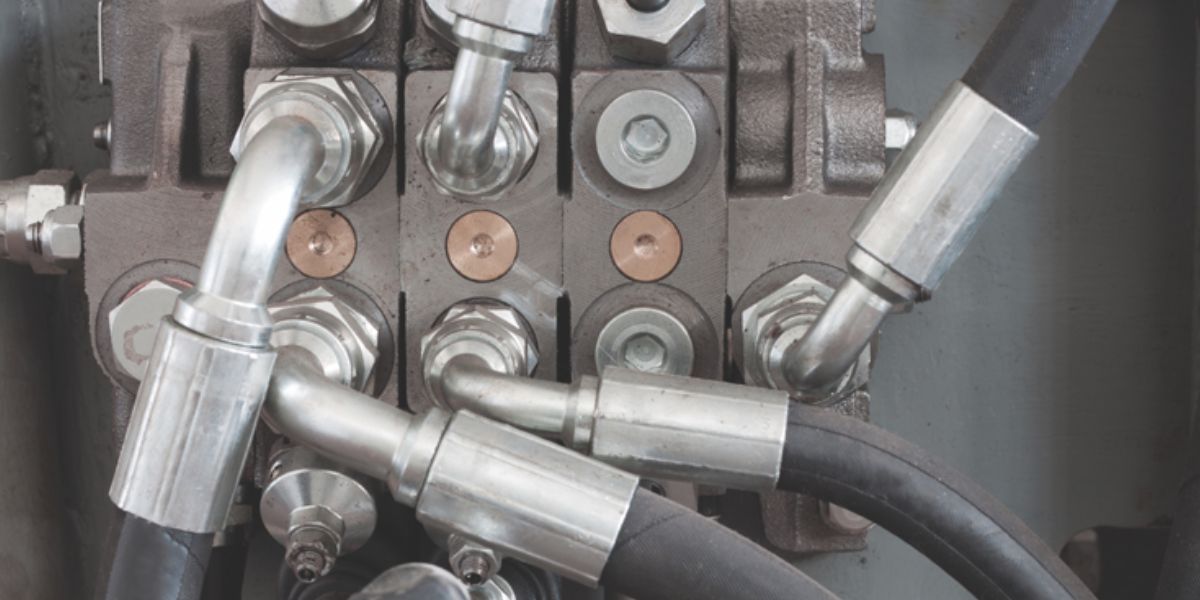

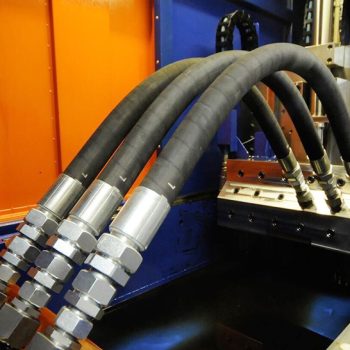

Industrial Machinery

In industrial machinery, where downtime is costly, JIC fittings provide the reliability and quick assembly needed to keep machines running smoothly. Whether in production lines, hydraulic presses or conveyor systems, these joints are essential.

Automotive

The automotive industry requires components that can withstand high pressures and harsh conditions. JIC fittings meet these requirements and are ideal for hydraulic braking systems, power steering systems and even fuel lines. they are durable and easy to assemble. They are durable and easy to assemble, especially for automotive applications where safety is paramount.

Aerospace

In aerospace and defense, where failure is not an option, JIC fittings are commonly used in the hydraulic systems of aircraft and military vehicles. Their high-pressure capabilities and stringent quality standards make them the preferred choice for applications where performance and reliability are paramount.

Hydraulic Equipment

JIC fittings are frequently used in general purpose hydraulic equipment such as pumps, cylinders, and valves. Their standardized dimensions and compatibility make them a practical choice for a variety of hydraulic systems.

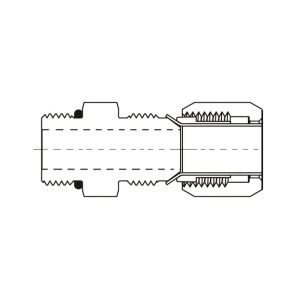

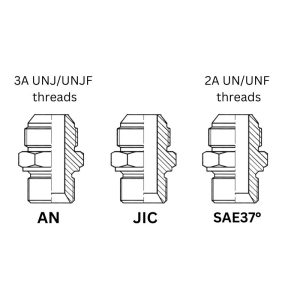

JIC vs AN

When it comes to hydraulic fittings, people often refer to both the JIC and the AN. While there are similarities, there are also key differences. Understanding these nuances will help you make an informed choice for your specific needs.

Similarities

Both JIC and AN fittings use a 37-degree flared seating surface to provide a secure, leak-proof connection. They are typically made of the same materials, such as steel and stainless steel, and are used in high-pressure applications. As a result, both types are suitable for a range of industries, from aerospace to automotive.

Differences

The main difference is in the threads.AN fittings use a special thread called the “J thread,” which is not commonly found in other fittings. JIC fittings, on the other hand, use a standard UNF (Unified National Fine Thread) thread, making them more versatile and easier to source.

Another difference is in certifications and standards. AN fittings generally meet military specifications and tend to be more expensive due to these stringent requirements. JIC fittings, while also meeting high quality standards, are generally more cost-effective and easier to find in the commercial market.

JIC vs SAE

In the field of hydraulic fittings, JIC and SAE are two standards that come up frequently. While they have some similarities, understanding their differences is critical to selecting the right fitting for your application.

Similarities

Both JIC and SAE fittings are commonly used in high-pressure applications and are made from high-quality materials such as steel and stainless steel. They are designed to provide a secure, leak-proof connection and are used in a variety of industries, including automotive and industrial machinery.

Differences

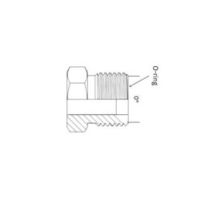

Sealing Mechanism

One of the most significant differences is the sealing mechanism; JIC fittings seal with a 37-degree flare, while SAE fittings typically seal with an O-ring The O-ring in SAE fittings provides an additional sealing layer, which can be advantageous in some applications The O-ring in SAE fittings provides an additional sealing layer, which can be advantageous in some applications.

Thread type

JIC fittings typically use UNF (Unified National Standard Fine Thread) threads, making them more versatile and suitable for a wider range of applications. SAE fittings, on the other hand, may use a variety of thread types, including NPTF (National Pipe Thread Fuel) and other threads, which may require an adapter for compatibility.

Standards and Certifications

JIC fittings are typically manufactured to industry standards and are therefore more universally applicable. SAE fittings are typically designed to meet specific automotive standards, which may make them more specialized but may also limit their wider applicability.

Cost

While both fittings are of high quality, SAE fittings are sometimes more expensive than JIC fittings due to their specialized standards and additional sealing mechanisms.

How to Select the Right JIC Fitting

Selecting the proper JIC fitting is critical to the success of your hydraulic system. Below are some key factors to consider in the selection process.

Size Considerations

The size of the hydraulic fitting is very important. Be sure to measure the inside and outside diameters of the hose or pipe to ensure a tight fit. jic fittings come in a variety of sizes, so accurate measurements will help you easily find the right fitting.

Material Selection

As mentioned earlier, JIC fittings are available in steel, stainless steel, and brass. Your choice depends on the specific application and environment. For corrosive environments, stainless steel is recommended, while for general applications, standard steel is usually sufficient.

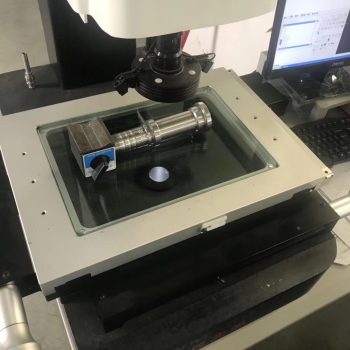

Quality Approvals

When selecting a JIC fitting, look for certifications or quality approvals. These include ISO certifications or other industry-specific standards to ensure that the fitting meets performance and safety criteria.

Installation and Maintenance

Proper installation and maintenance of the JIC fittings is critical for optimal performance and longevity of your hydraulic system. The following guidelines are provided to assist you in this process.

Pre-Installation Inspection

Before beginning installation, inspect the fitting for visible defects such as cracks or distortion. Also, make sure the threads are clean and free of debris. A quick inspection can prevent potential problems from occurring.

Installation Steps

Thread preparation: If necessary, apply a thin layer of thread sealant, but avoid using too much to avoid hydraulic contamination.

Hand tighten: First hand tighten the fitting to the mating part to ensure proper alignment.

Torque application: Use a torque wrench to tighten the fitting to the manufacturer’s specifications. Over-tightening can cause thread damage, while under-tightening can cause leaks.

Maintenance Tips

Periodic inspection: Inspect fittings periodically for leaks, cracks, or any signs of wear.

Replace: If any problems are found during inspection, replace the defective fitting immediately to prevent system failure.

Clean: Keep the area around the fitting clean to minimize the risk of contamination.

Take the Next Step with Topa

Ready to elevate your hydraulic systems with top-quality JIC fittings? At Topa Hydraulic, we offer a wide range of JIC fittings that meet rigorous industry standards. Our one-stop services are designed to meet all your hydraulic component needs, ensuring quality, durability, and cost-effectiveness.

Don’t settle for less when you can have the best. Contact Topa today to find out how we can make your hydraulic systems more efficient and reliable.

Conclusion

JIC fittings are more than just components; they’re the backbone of efficient and reliable hydraulic systems. From their standardized dimensions to their versatile material options, JIC fittings offer unparalleled advantages for professionals in various industries. Whether you’re involved in industrial machinery, automotive systems, or aerospace, choosing JIC fittings is a decision that pays off in performance and reliability.

FAQ

In general, reusing fittings is not recommended as it can compromise the integrity of your hydraulic system.

Life expectancy varies by application and maintenance, but with proper maintenance, quality fittings can last for years.

SAE and JIC fittings may look similar and even fit together due to their 37-degree flare, they are not always interchangeable.

JIC fittings are designed to provide a secure, leak-proof connection without the need for additional sealants, thanks to their 37-degree flare seating surface. However, proper installation and regular inspection are crucial for maintaining the integrity of the seal.

JIC fittings typically use UNF threads similar to AN and some SAE fittings, with 37 degree flare being a distinguishing feature of JIC fittings.