What is DIN Hydraulic Fitting?

Table of Contents

Introduction

Hydraulic systems are integral to modern machinery, and the role of DIN hydraulic fittings in these systems is crucial. These fittings, standardized by the German Institute for Standardization (Deutsches Institut für Normung), are not just components; they are the backbone of countless hydraulic applications, ensuring efficiency and safety. In this exploration, we will delve into the origins, types, and applications of DIN hydraulic fittings. Understanding their significance and versatility is key to leveraging their full potential in various industrial contexts.

The Origin and Meaning of DIN

The DIN standard originated from the German Institute for Standardization, known in German as “Deutsches Institut für Normung.” This organization established the DIN standard to facilitate consistency and standardization across various industrial components, including hydraulic fittings. This standard has been instrumental in unifying design specifications, dimensions, and quality benchmarks. The acronym DIN itself stands for “Deutsches Institut für Normung,” indicating its origin and primary purpose in standardizing products and components. The implementation of the DIN standard across industries is pivotal for ensuring interoperability, quality, and reliability of products, including hydraulic fittings, on a global scale.

Types of DIN Hydraulic Fittings

DIN hydraulic fittings represent a diverse spectrum of designs, each meticulously engineered to meet distinct application needs and pressure specifications. In the realm of hydraulic systems, these fittings are indispensable for establishing connections between hoses, tubes, and pipes. Their primary function is to secure these connections, ensuring they remain leak-free even under different pressure conditions which can vary widely depending on the application.

The design of DIN fittings is governed by rigorous standards, ensuring uniformity in size, shape, and function. This uniformity is crucial in maintaining the integrity and efficiency of hydraulic systems. Different types of DIN fittings are optimized for specific situations – for instance, some are better suited for high-pressure environments, while others are designed for systems where vibration or rotational forces are a concern.

Each fitting type under the DIN standard is characterized by its unique connection mechanism and sealing technique. These mechanisms are designed to provide maximum sealing efficiency, minimize the risk of leakage, and maintain structural integrity under pressure. For example, some DIN fittings employ a cutting ring design that bites into the tube to form a secure seal, ideal for high-pressure applications. Others might use an O-ring seal or a flared connection, depending on the specific requirements of the system.

Types of DIN Hydraulic fittings

DIN 2353 Tube Fittings

Characterized by their cutting ring design, DIN 2353 tube fittings are widely utilized in high-pressure hydraulic systems. The cutting ring acts as a biting mechanism, creating a secure and leak-proof connection when tightened onto a tube. This unique feature enables them to handle high-pressure conditions effectively, making them a popular choice for robust hydraulic applications.

24° Cone Fittings

These fittings are distinguished by their 24-degree cone, commonly employed with metric tubes. The cone angle is specifically designed to offer a tight and efficient seal, which is critical in medium to high-pressure systems. The 24° cone fittings’ design ensures reliable performance in a range of hydraulic applications, providing a solid connection that can withstand significant pressure variations.

Flare DIN Fittings

Similar to 24° cone fittings, DIN flare fittings are designed for use in high-pressure applications. They typically feature a flared tube end, which mates with a corresponding tapered seat in the fitting body. This flaring allows for a larger contact area, enhancing the strength and reliability of the connection.

DIN Banjo Fittings

These fittings are recognized for their distinct banjo-shaped body, allowing for a compact and efficient hose connection. DIN banjo fittings are especially useful in tight spaces where traditional fittings may not fit. They provide a secure, leak-proof connection, making them suitable for moderate pressure applications.

DIN Screw-in Fittings

Designed for ease of installation, these fittings feature a screw-in mechanism that allows for quick and simple assembly. DIN screw-in fittings are versatile and can be used in a variety of hydraulic systems, offering a reliable connection that is both easy to install and maintain.

Swivel DIN Fittings

These fittings are designed for applications where rotational or oscillating movements are present. The swivel feature allows for free movement of the connected hose or tube, reducing stress and preventing kinking or twisting. DIN swivel fittings are ideal for dynamic hydraulic systems where movement flexibility is crucial.

DIN vs SAE

Design

DIN Fittings: These fittings generally adhere to a metric design specification. A common feature in DIN fittings is the 24° cone used for sealing purposes. This design is tailored to ensure a tight and effective seal, particularly suited for high-pressure environments.

SAE Fittings: In contrast, SAE (Society of Automotive Engineers) fittings frequently employ a 37° flared or an O-ring face seal design. The 37° flared design provides a robust seal and is often used in applications where high pressure is a factor. The O-ring face seal offers a high degree of leak resistance and is suitable for a variety of hydraulic applications.

Regional Preferences

The preference for either DIN or SAE standards is largely influenced by regional manufacturing and engineering practices. In Europe and Asia, DIN standards are more prevalent due to their alignment with the metric system and regional engineering norms. These regions have a long-standing tradition of using DIN standards, which are deeply integrated into their industrial and manufacturing sectors.

Conversely, North American industries show a strong preference for SAE standards. This preference is rooted in the historical development of engineering practices in the region, where the Imperial system and SAE standards have been the norm.

Are DIN fittings Metric?

Yes, DIN fittings are indeed metric. This is a fundamental aspect of their design and specification. The adherence to the metric system is a key distinguishing feature of DIN (Deutsches Institut für Normung) fittings. The metric system, which uses units such as millimeters (mm) for length and dimensions, and the Pascal (Pa) or bar for pressure measurements, is the basis for all dimensions, threads, and specifications of DIN fittings.

Materials of DIN Fittings

DIN hydraulic fittings are predominantly made from two types of materials: stainless steel and carbon steel. Each material is chosen based on specific application requirements.

Stainless Steel: Stainless steel is highly favored for its corrosion resistance, making it ideal for hydraulic systems exposed to corrosive environments or those handling corrosive fluids. It maintains its integrity even under harsh conditions, ensuring longevity and reliability. Stainless steel fittings are often used in food processing, marine applications, and chemical industries.

Carbon Steel: Carbon steel is commonly used due to its high strength and durability. It is suitable for high-pressure applications and where robustness is a primary concern. Carbon steel fittings are cost-effective and widely used in general industrial, automotive, and construction applications. However, they are more susceptible to corrosion compared to stainless steel and may require protective coatings or treatments for certain applications.

Advantages of Using DIN Hydraulic Fittings

Comparative Analysis

DIN hydraulic fittings offer several advantages over other types of fittings, making them a preferred choice in many hydraulic applications.

Superior Reliability: DIN fittings are known for their exceptional reliability. Their design and manufacturing standards ensure a consistent and dependable performance, which is crucial in hydraulic systems where failures can be costly and dangerous.

Enhanced Durability: The materials used in DIN fittings, typically stainless and carbon steel, provide robustness and longevity. These materials are chosen for their ability to withstand harsh conditions, including high pressures, extreme temperatures, and corrosive environments.

High Efficiency: The precision engineering of DIN fittings contributes to their efficiency. They ensure a tight and secure connection, minimizing the risk of leaks, which is essential for maintaining the efficiency of hydraulic systems.

Unique Benefits

DIN hydraulic fittings also offer unique benefits that add value to their application in various systems.

Leak-Proof Designs: One of the most significant advantages of DIN fittings is their leak-proof design. The precision with which these fittings are made ensures that connections are secure, reducing the likelihood of leaks, which can lead to system inefficiencies and safety hazards.

Ease of Maintenance: DIN fittings are designed for ease of assembly and disassembly, making maintenance tasks simpler and more efficient. Their standardized dimensions also mean that replacement parts are easier to source and fit.

Versatility: DIN fittings are versatile in their application. They are suitable for a wide range of pressures and temperatures, and their standardized design makes them compatible with a variety of hydraulic systems and components. This versatility makes them an ideal choice for a broad spectrum of industries, including automotive, manufacturing, aerospace, and more.

How to Choose the Right DIN Fittings

When selecting the right DIN hydraulic fittings for a particular system, several key factors must be considered to ensure optimal performance and compatibility. Here are guidelines and factors to consider:

Guidelines

Size Selection: The size of the fitting is critical. It must match the size of the hoses, tubes, or pipes in the hydraulic system. Using fittings of the incorrect size can lead to leaks or system failures. Refer to the system’s specifications or consult with a hydraulic expert to determine the appropriate size.

Pressure Rating: Each fitting has a maximum pressure rating. Choose a fitting whose pressure rating meets or exceeds the maximum operating pressure of your hydraulic system. Using a fitting with a lower pressure rating than required can result in fitting failure under high-pressure conditions.

Material Selection: Consider the material of the fitting based on the application. Stainless steel fittings offer corrosion resistance and are suitable for harsh environments, while carbon steel fittings are appropriate for less demanding conditions. The material should be chosen based on the operational environment and the fluid type used in the system.

Factors to Consider

Compatibility with Existing Systems: Ensure that the DIN fittings are compatible with the existing components in your hydraulic system. This includes not only size and thread type but also material compatibility, especially if you are integrating the fitting into an existing system.

Environmental Conditions: Consider the environment in which the system will operate. Temperature extremes, exposure to corrosive substances, and the presence of vibrations or shocks can impact the suitability of certain fittings.

Fluid Compatibility: The hydraulic fluid used in the system must be compatible with the material of the fittings. Some fluids can cause corrosion or degradation of certain materials. Ensure that the material of the fitting is compatible with the type of hydraulic fluid used.

Application-Specific Requirements: Depending on the application, there might be additional requirements to consider, such as the need for fittings with a specific certification or those designed for use in food-grade applications or explosive environments.

Installation and Measurement Tips

Installing DIN hydraulic fittings correctly is crucial for the safety and functionality of the hydraulic system. Here’s a step-by-step guide and measurement tips:

Step-by-Step Guide for Installation

Preparation: Ensure that the tube or hose ends are clean, free from debris, and cut squarely. Any burrs should be removed to prevent damage to the fitting and sealing surfaces.

Inspection: Before installation, inspect the fittings for any damage or imperfections. Check the threads and sealing surfaces for cleanliness and integrity.

Lubrication: Lightly lubricate the threads and any moving parts of the fitting, such as the nut or cutting ring. Use a lubricant that is compatible with the system’s hydraulic fluid.

Assembly: For threaded fittings, start by hand-threading to avoid cross-threading. Once hand-tight, use the appropriate tools to tighten the fitting to the manufacturer’s specifications. For compression-type fittings (like DIN 2353), insert the tube into the fitting, ensuring it is seated properly, then tighten the nut by hand until resistance is felt.

Final Tightening: Use two wrenches to tighten the fitting – one to hold the fitting body and the other to turn the nut. Tighten to the manufacturer’s recommended torque setting, usually provided in their specifications or installation guide.

Inspection: After installation, inspect the assembly to ensure it is secure and properly aligned. There should be no gaps between the fitting components.

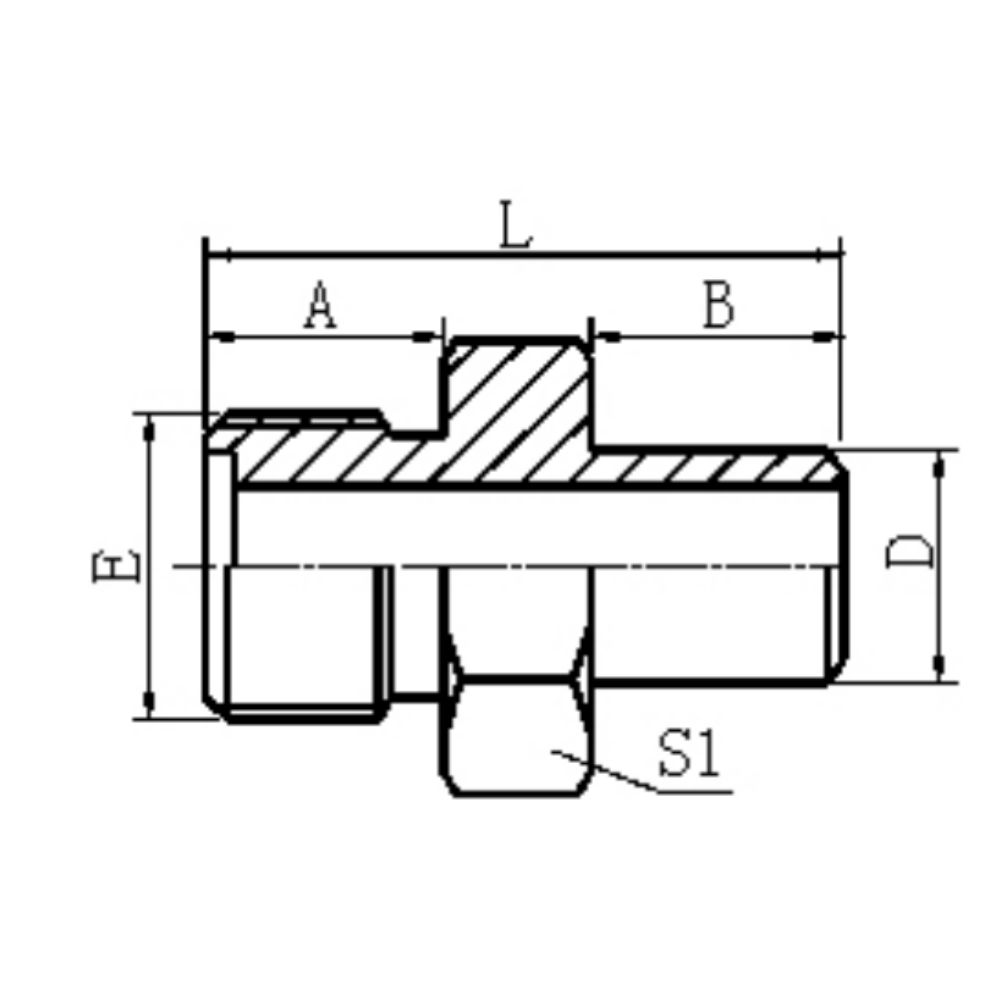

Measurement Tips

Determining Size: To replace or install new fittings, you need to know the correct size. Measure the outer diameter of the tube or hose for tube fittings. For thread size, measure the diameter of the male thread or the inside diameter of the female thread.

Thread Identification: If the fitting is threaded, identify the thread type (metric, BSP, etc.). Use a thread gauge or compare with a known thread type to ensure compatibility.

Length Measurement: When measuring the length of a hose assembly, include the fitting end connections. Measure from the end of one fitting to the end of the other.

Angle and Orientation: For fittings like elbows or tees, note the orientation of the fitting ends. Accurate measurement of angles ensures that the new fitting will align correctly in the system.

Conclusion

In conclusion, understanding and implementing the correct use of DIN hydraulic fittings is essential for the efficiency, safety, and reliability of hydraulic systems. From the historical origins of the DIN standard to the intricate details of fitting types, materials, and manufacturing processes, each aspect plays a vital role in ensuring optimal system performance. Understanding these nuances not only ensures the functional integrity of hydraulic systems but also enhances their safety and effectiveness in demanding environments.