How to Maintain Reusable Hydraulic Hose Fittings

Table of Contents

Introduction

Reusable hydraulic hose fittings, known for their versatility and cost-effectiveness, allow for quick modifications and repairs in the field without the need for specialized tools. Proper care of these fittings is essential to prevent system failures, reduce downtime, and ensure the safety of operations. This article delves into the best practices for maintaining reusable hydraulic fittings, helping you extend their life span and optimize your hydraulic system’s performance.

How to maintain reusable hose fitting?

To maintain reusable hose fittings, ensure proper installation and regular inspections for leaks and wear. Use compatible hoses, clean fittings regularly, and apply the correct torque during assembly. Replace worn parts promptly to prevent system failures and extend fitting lifespan.

Common Reusable Fitting Problems

In hydraulic systems, reusable hose fittings are a critical component, but they are susceptible to several common issues that can compromise their efficiency and the overall system integrity. Identifying and addressing these issues promptly is key to maintaining system performance. Below are detailed descriptions of typical problems that occur with reusable hydraulic fittings:

Leakage Issues

Leakage is one of the most frequent problems in hydraulic systems, particularly with reusable fittings. Several factors contribute to leaks:

Improper Installation: Incorrect fitting installation, such as inadequate tightening or not following the correct threading procedures, can lead to gaps or misalignment, causing leaks.

Worn-Out Seals: Over time, seals can degrade due to mechanical wear, exposure to extreme temperatures, or contact with corrosive fluids. This deterioration compromises the seal, allowing fluid to escape.

Loose Connections: Vibration and regular system operation can loosen fittings over time, necessitating regular checks to ensure tightness.

Corrosion and Wear

Reusable fittings can suffer from corrosion and general wear, which diminish their effectiveness and can lead to system failures:

Environmental Exposure: Conditions such as high humidity, saltwater exposure, and contact with aggressive chemicals can accelerate the corrosion of metal components.

Fluid Contamination: Hydraulic fluids contaminated with water, dirt, or other particulates can corrode fittings from the inside, often going unnoticed until a failure occurs.

Material Degradation: Some materials used in fittings can degrade over time, especially if the wrong type of hydraulic fluid is used or if they are exposed to high temperatures frequently.

Misalignment and Vibration

Misalignment and vibration can also lead to significant issues in the integrity and functionality of hydraulic fittings:

System Vibration: Machinery and equipment vibrations can cause fittings to shift out of alignment, leading to uneven wear and potential failures.

Improper Alignment at Installation: If fittings are not aligned correctly during installation, it can result in uneven force distribution when the system is pressurized, which may lead to leaks or ruptures.

Thermal Expansion: Differences in thermal expansion rates between materials can lead to misalignment over time, especially in systems experiencing wide temperature fluctuations.

Abrasive Wear

Aside from the typical wear and tear, abrasive wear is a specific type of deterioration that affects reusable fittings:

Abrasive Particles: Particles in the hydraulic fluid can wear down the fitting surfaces, especially in systems without adequate filtration.

High-Velocity Fluids: In systems where fluid is moved at high velocities, the increased turbulence can accelerate the wear on fittings, reducing their lifespan.

Benefits of Proper Maintenance

Proper maintenance of reusable hydraulic hose fittings is essential for maximizing the efficiency, safety, and longevity of hydraulic systems. Here are the key benefits of adhering to a rigorous maintenance schedule:

Extended Equipment Lifespan

Durability: Regular maintenance ensures that fittings and hoses are in optimal condition, which reduces the likelihood of premature failure. By addressing issues like minor leaks or wear before they escalate, the components last significantly longer.

System Integrity: Maintaining hose fittings properly helps in preserving the structural integrity of the entire hydraulic system. This is crucial in applications where system failure could lead to significant operational disruptions.

Reduced Downtime and Costs

Preventive Measures: Scheduled inspections and maintenance allow for the identification and rectification of potential issues before they develop into major problems. This proactive approach minimizes unexpected breakdowns.

Cost Efficiency: Although maintenance involves some upfront costs, it is far less expensive than the costs associated with system downtime, emergency repairs, or complete replacements of major components due to neglect.

Enhanced Safety

Leak Prevention: Proper maintenance includes ensuring all fittings are tightly secured and seals are in good condition, which significantly reduces the risk of dangerous leaks. Hydraulic fluid leaks can create slip hazards and pose fire risks in certain environments.

System Reliability: A well-maintained hydraulic system is more reliable. Reliability is crucial in applications such as industrial machinery, automotive hydraulics, and agricultural equipment where safety and operational continuity are paramount.

Improved System Performance

Efficiency: Clean and well-maintained components function more efficiently. Regular maintenance ensures that hydraulic fluids are free of contaminants that can reduce efficiency and increase wear on system components.

Response Time: Hydraulic systems with well-maintained fittings respond more quickly and perform better, which is crucial in applications where precision and responsiveness are necessary.

Sustainability

Resource Conservation: By extending the life of existing components and reducing the need for replacements, maintenance practices contribute to sustainability. This is particularly important in industries looking to reduce their environmental footprint.

Waste Reduction: Proper maintenance reduces the need for new parts, which in turn decreases the waste associated with disposing of old, worn-out components.

Routine Maintenance Procedures

Maintaining reusable hose fittings involves a series of routine checks and procedures designed to ensure optimal performance and prevent failures. Here is a detailed breakdown of essential maintenance actions:

Inspection Routines

Visual Inspection:

Regularly examine the external condition of the fittings for signs of wear, corrosion, or damage.

Check for cracks, dents, or any deformations on the fitting surfaces.

Ensure that the fittings are not leaking any fluid.

Thread and Seal Inspection:

Inspect the threads for any signs of stripping or cross-threading that could impair the fitting’s integrity.

Check the condition of all seals and O-rings, looking for cracks, brittleness, or other signs of deterioration.

Tightness and Alignment Check:

Ensure all fittings are tightened to the manufacturer’s specifications using appropriate tools.

Check the alignment of connected components to ensure there is no undue stress on the fittings.

Cleaning and Care

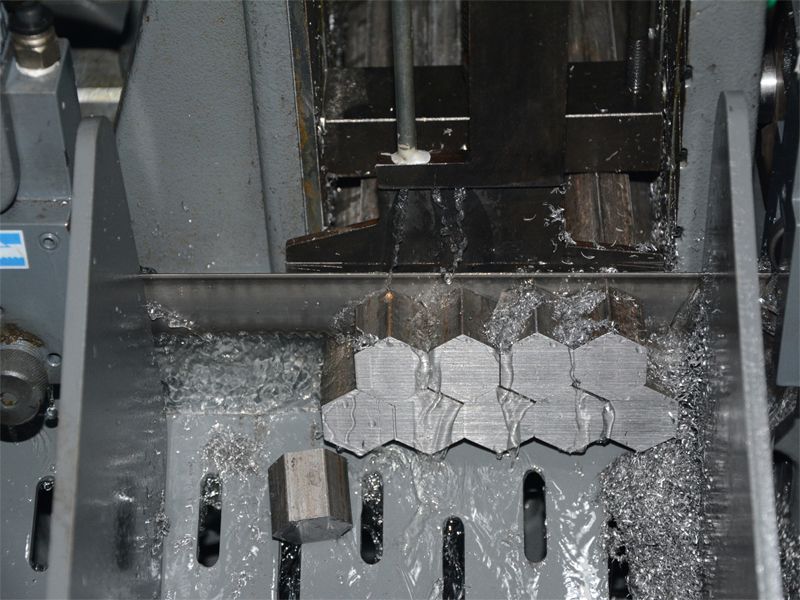

Cleaning Procedures:

Clean the fittings regularly using appropriate solvents that do not degrade the material of the fittings or seals.

Remove any debris, dirt, or contamination that could enter the hydraulic system.

Lubrication:

Apply suitable lubricants to the threads and moving parts of the fittings to ensure smooth operation and prevent corrosion.

Use lubricants that are compatible with the hydraulic fluid used in the system.

Protective Coatings:

Apply anti-corrosion sprays or protective coatings if the fittings are exposed to harsh environmental conditions.

Replacement Schedules

Seal Replacement:

Replace seals and O-rings at intervals recommended by the manufacturer or sooner if any signs of wear or leakage are detected.

Fitting Replacement:

Establish a schedule for inspecting and possibly replacing critical fittings based on their operating environment and frequency of use.

Replace any fittings that show signs of significant wear, corrosion, or damage immediately to prevent system failures.

Record Keeping

Maintenance Logs:

Keep detailed records of all inspections, cleanings, and replacements. This documentation will help in tracking the lifespan of each component and planning future maintenance activities.

System Performance Monitoring:

Regularly check the performance of the hydraulic system to identify any changes that might indicate issues with fittings or other components.

By following these detailed maintenance steps, the longevity and reliability of reusable hydraulic fittings can be significantly enhanced, ensuring that the hydraulic systems they serve operate smoothly and efficiently.

Means of Repair after a Failure

Tools and Equipment for Repair

Hydraulic Wrenches and Sockets

Purpose and Usage: Hydraulic wrenches and sockets are essential for applying the correct torque to hydraulic fittings. These tools help prevent over-tightening and under-tightening, which can lead to leaks or damage to components.

Calibration: Regularly calibrate torque tools to maintain accuracy in torque application, which is crucial for the longevity and reliability of the fittings.

Seal Installation Tools

Types of Tools: Seal installation tools include cone-shaped and cylindrical seal drivers and picks used for removing old seals and seating new ones properly.

Preventing Damage: These tools are designed to apply even pressure to seals during installation, preventing damage such as stretching, tearing, or pinching, which could compromise the seal’s effectiveness.

Material Considerations: Choose tools made from materials that are softer than the metal of the fittings, such as plastic or coated metals, to avoid scratching or damaging the surface of the fittings or seals.

Cleaning Supplies

Selection of Cleaners: Choose cleaners that are specifically formulated for use in hydraulic systems. These should effectively remove oils, greases, and other contaminants without degrading the hydraulic fluids or damaging the system components.

Brushes and Cloths: Include various sizes of brushes and non-abrasive cloths for cleaning different parts of the fittings and nearby areas. Brushes should have bristles that are stiff enough to remove debris but not so hard as to scratch metal surfaces.

Safety and Handling: Ensure that all cleaning supplies are used in a well-ventilated area and stored safely. Use appropriate personal protective equipment (PPE) such as gloves and goggles when handling chemical cleaners.

Additional Useful Tools

Pressure Gauges: Use these to test system pressure after repairs to ensure that it is within operational specifications.

Leak Detection Equipment: In cases where leaks are not visually apparent, using ultrasonic leak detectors or dye injection kits can help in identifying and locating leaks.

Immediate Response to Failure

Immediate Response to Failure

System Shutdown:

- Safety First: As soon as a failure is detected, the first step is to ensure the safety of all personnel by shutting down the hydraulic system. This prevents the system from operating under faulty conditions, which can exacerbate the problem and pose serious safety risks.

- Control Panel Operation: Use the system’s control panel to execute an immediate shutdown. In systems without an automated shutdown process, manual valve closures may be necessary.

- Pressure Release: Safely release any stored pressure in the system to prevent accidental discharges or further damage during the repair process.

Leak Containment:

- Identify the Source: Quickly identify the source of the leak. This may involve visual inspections or using leak detection equipment if the source is not immediately apparent.

- Containment Measures: Use drip pans or absorbent materials to contain the hydraulic fluid. In cases where there is a significant spill, deploy environmental containment measures such as booms or absorbent barriers.

- Fluid Collection: Collect the leaking hydraulic fluid for proper disposal or recycling. Ensure that all collected fluid is handled according to local environmental regulations.

Damage Assessment:

- Visual Inspection: Begin with a visual inspection to assess the extent of damage. Look for signs of wear, fatigue, or mechanical failure on the fittings and surrounding components.

- Component Testing: Employ testing methods such as pressure tests or ultrasonic testing to evaluate the integrity of the fittings and detect any hidden damages.

Repair Techniques for Different Failures

Leakage at Fitting Joints

Tightening:

- Tools and Techniques: Use torque wrenches to ensure that fittings are tightened according to the manufacturer’s specified torque settings. This prevents over-tightening, which can damage threads and seals.

- Regular Monitoring: After tightening, monitor the joints during initial system re-pressurization to ensure that the leak has been effectively sealed.

Seal Replacement:

- Identify Seal Type: Determine the type of seal used in the fitting—whether an O-ring, gasket or another type—and check its compatibility with the hydraulic fluid and operating temperature.

- Proper Installation: When replacing seals, clean all contact surfaces thoroughly to remove any residue or particulates. Lubricate new seals lightly with hydraulic fluid before installation to prevent damage during fitting.

Thread Repair:

- Thread Inspection Tools: Use thread gauges to assess the extent of thread damage. This will help determine whether the threads can be repaired or if the fitting needs to be replaced.

- Using Thread Repair Kits: If threads are slightly damaged, use thread repair kits, such as thread inserts or taps, to restore the original thread profile, ensuring a secure fit.

Corrosion-Related Failures

Cleaning and Coating:

- Corrosion Removal: Use wire brushes, sandblasting, or chemical rust removers to clean the corroded areas thoroughly. Ensure that all loose material is removed to provide a clean surface for coating.

- Application of Coatings: Apply corrosion-resistant coatings such as zinc or epoxy-based paints, which provide a durable barrier against environmental factors that cause corrosion.

Component Replacement:

- Assessment of Structural Integrity: Evaluate whether the corrosion has affected the structural integrity of the fitting. Pay particular attention to pits or material loss that might compromise the fitting’s strength.

- Installation of New Fittings: Choose materials that offer better corrosion resistance suitable for the specific environmental conditions of the system.

Cracks and Breaks

Welding or Brazing:

- Feasibility Assessment: Assess the feasibility of welding or brazing based on the material of the fitting and the nature of the crack. Not all materials are suitable for these repair methods.

- Professional Repair: Ensure that welding or brazing is done by certified professionals who can guarantee the strength and durability of the repair.

Replacement:

- Safety and Reliability: Consider the safety and reliability of the hydraulic system as the primary factors in deciding whether to repair or replace a fitting. In most cases, replacement is recommended for fittings with visible cracks or breaks.

- Upgrade Options: When replacing, consider upgrading to higher-quality materials or designs that might offer improved performance and longer lifespan.

When to Replace Rather than Repair?

Deciding whether to replace or repair hydraulic hose fittings is crucial for maintaining the safety, efficiency, and longevity of hydraulic systems. Here are the key scenarios when replacement is recommended over repair:

Extent of Damage: If the damage to a fitting is extensive, such as deep cracks, breakage, or severe deformation, repair may not restore the fitting to a fully functional state. In such cases, replacement is necessary to ensure the integrity and safety of the system.

Long Term Problems: Repeatedly failing fittings may indicate a potential problem with the type of fitting, the material, or the specific requirements of the design and application. Continuing to repair such fittings is not only uneconomical, it can jeopardize the integrity of the system.

Signs of Wear: Fittings that show signs of significant wear, such as erosion, thread wear, or persistent leakage, should be replaced. Wear can affect the proper and safe operation of fittings.

Conclusion

Maintaining reusable hydraulic hose fittings is essential for ensuring the efficiency, reliability, and safety of hydraulic systems. Implementing a structured maintenance program can significantly reduce operational costs and enhance system longevity. For any uncertainties or complex issues, seeking professional advice is recommended to maintain system integrity.

FAQ

It’s advisable to inspect reusable hose fittings regularly, typically every three to six months, depending on their usage frequency and the environmental conditions they are exposed to. Regular inspections help identify wear and tear early, preventing leaks and potential system failures.

Key signs of wear include cracks, corrosion, and any deformation such as stretching or bending in the fittings. Also, check for any signs of leakage around the fittings, which can indicate a seal failure or damage to the fitting itself.

Clean reusable hose fittings using a mild soap solution and warm water to remove any dirt, grime, or residual hydraulic fluid. Avoid using harsh chemicals or abrasive tools that could damage the fitting’s surface. Ensure the fittings are completely dry before reassembly and reuse.

Replace reusable hose fittings if they show signs of significant wear, such as deep scratches, cracks, or irreversible corrosion. Also, replace them if they have been involved in a system failure or if they no longer provide a secure and leak-free connection even after proper installation.