FAQ

What is ORFS fitting?

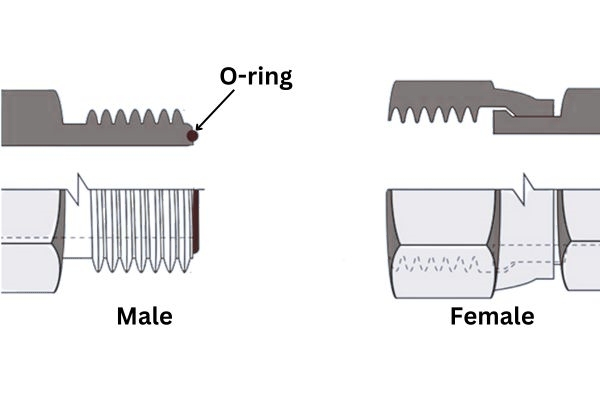

ORFS uses an O-ring compression mechanism for sealing.

Female Orfs fitting has a flat surface and a straight thread UNF swivel nut.

Male Orfs fitting is a straight thread

What are the Precautions for installing ORFS hydraulic fittings?

Step 1. Check for possible contamination or damage during shipping or handling. Verify that the face seal O-ring is properly installed.

Step 2: Lubricate threads and O-rings with your system hydraulic fluid or light lubricant.

Lubricate the system with hydraulic fluid or light lubricant.

Step 3: Align the matching face seal with the O-ring and tighten the face seal.

Tighten the end seal nut.

Step 4: Tighten the packing nut to the value shown in the table on the left side of this manual.

What is a disadvantage of ORFS hydraulic fittings?

As with ORB fittings, they are limited in performance when subjected to temperature ranges. O-rings can melt or corrode if the temperature is too high or the media is incompatible. One phenomenon to be aware of is O-ring dislodgement, especially when it occurs during assembly. The O-ring may fall out of its groove, resulting in improper sealing, O-ring entrapment outside of the intended surface, and thread damage due to over-tightening. In such cases, the O-ring and ORFS hydraulic fitting may suffer irreparable damage, rendering it completely unusable. Therefore, care must be taken to ensure that the O-ring is properly placed prior to assembly. The use of adhesive material during assembly may help to overcome this problem.

What is the warranty of ORFS hydraulic fittings?

It is usually one year since sell day.

Why use ORFS fittings ?

In addition to providing a more reliable connection seal, this coupling design offers.

Zero clearance for easy piping

Over-torque resistance/eliminates damage caused by over-tightening

Vibration resistance/reduces loosening caused by system vibration

What may cause ORFS hydraulic fittings to leak?

Wrong installation operation, the mismatch between system and ORFS hydraulic fittings, poor product quality, etc. All these may lead to leakage.

Can ORFS hydraulic fittings be used in tight places?

Yes, ORFS hydraulic fittings have a straight threaded male fitting, an O-ring sealed to the female thread, and a rotatable female fitting, thus allowing for flexibility in a wide range of situations.

Comparison between ORFS and ORB?

Both are straight threaded, the difference is the sealing method, ORFS hydraulic fittings uses both metal and O-ring for sealing, and ORB hydraulic fittings are sealed by O-ring.

How does JIC compare to ORFS hydraulic fittings ?

The JIC hydraulic fittings is a metal-to-metal seal in the form of a 37-degree flared tube. ORFS hydraulic fittings is a better seal in the form of an O-ring seal and a metal seal. the JIC should be used for fuels and fluids at higher pressures, the ORF is more focused on hydraulic systems under vibration conditions.

What ORFS hydraulic fittings materials are available?

316 or 304 stainless steel

carbon steel

And brass