What is a D.O.T. Air Brake Fitting

Introduction

Air brake systems are an integral component of commercial vehicles, playing a pivotal role in ensuring the safety and efficiency of these heavy-duty transports. These systems utilize compressed air as a force for braking, offering a reliable and effective means of slowing down and stopping large vehicles, such as trucks and buses. The design and operation of air brake systems are complex, involving various components like compressors, reservoirs, brake chambers, valves, and fittings, each contributing to the precise control and distribution of air pressure throughout the system.

Understanding D.O.T. Air Brake Fittings

Definition of D.O.T. Air Brake Fittings

D.O.T. Air Brake Fittings are specialized components designed for use in the air brake systems of commercial vehicles, such as trucks and buses. These fittings are engineered to connect air brake lines, ensuring the secure and leak-proof transmission of compressed air that is used to operate the brake system. The “D.O.T.” designation indicates that these fittings comply with the safety standards set by the Department of Transportation, making them suitable for use in commercial transportation due to their reliability and durability.

Purpose and Necessity in Air Brake Systems

The primary purpose of D.O.T. Air Brake Fittings is to ensure a secure and efficient connection between the components of an air brake system. These fittings are crucial for maintaining the integrity of the air brake system, preventing air leaks, and ensuring that the correct air pressure is delivered to each part of the system when needed. Given the critical role of air brakes in the safety of heavy commercial vehicles, the reliability of these fittings directly impacts the overall safety and performance of the vehicle. Without high-quality, compliant fittings, the effectiveness of the air brake system could be compromised, leading to increased risk of brake failure and accidents.

Types of D.O.T. Air Brake Fittings

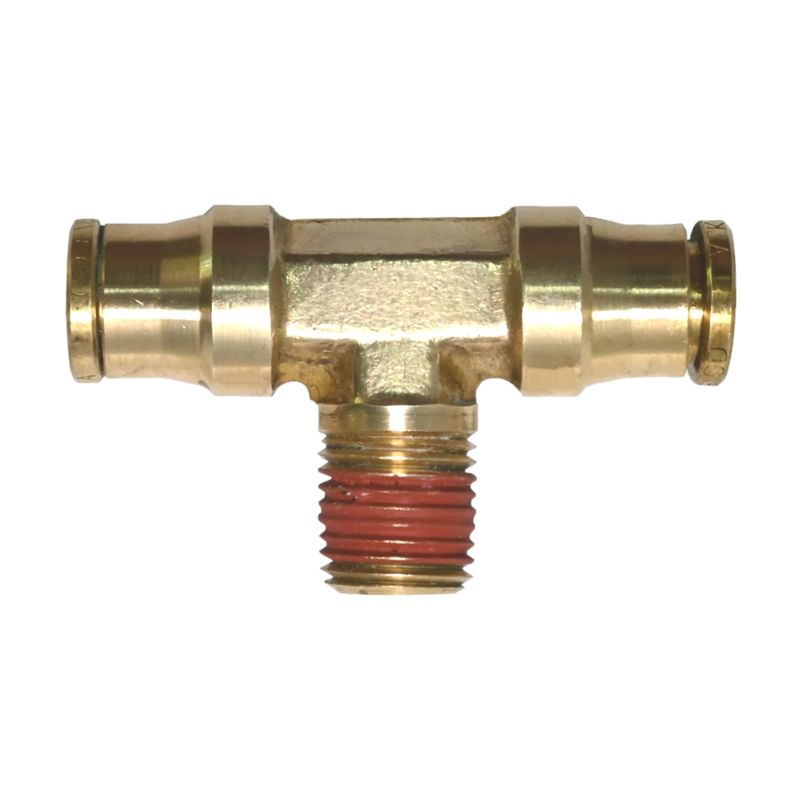

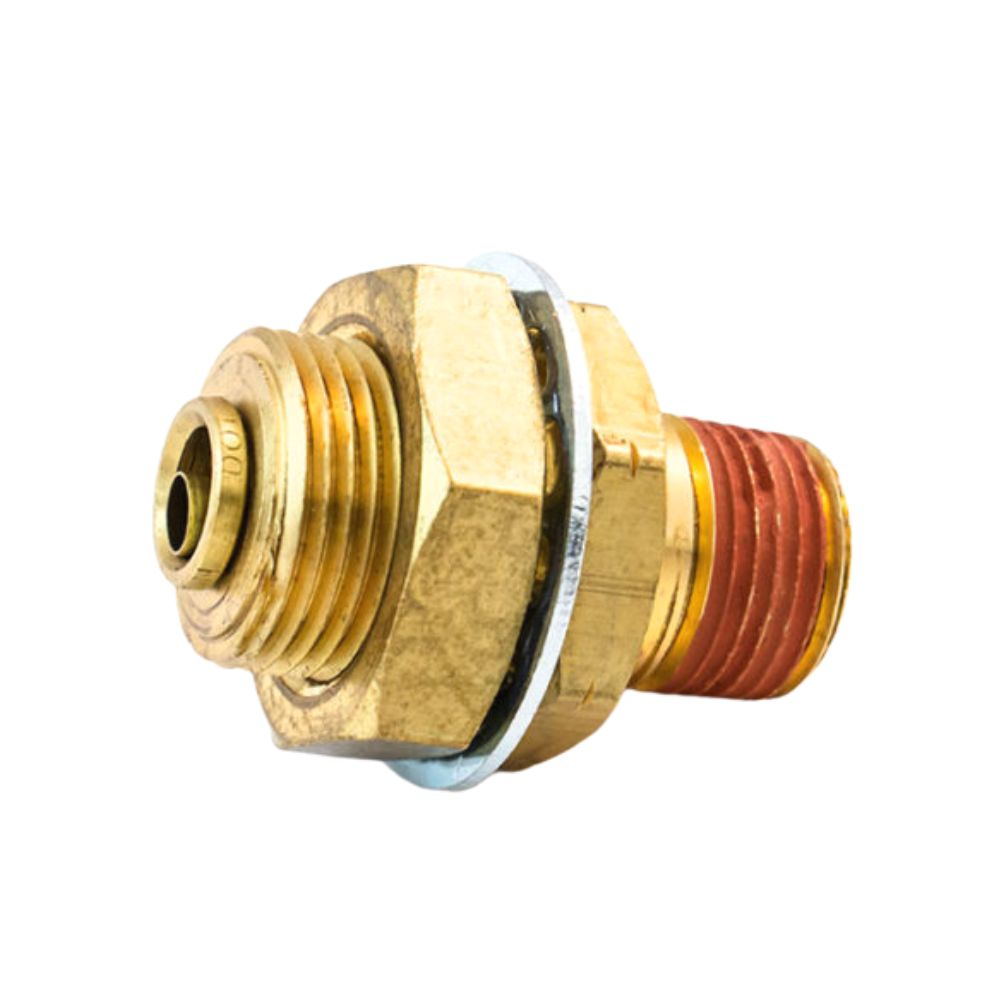

Push-to-Connect Fittings

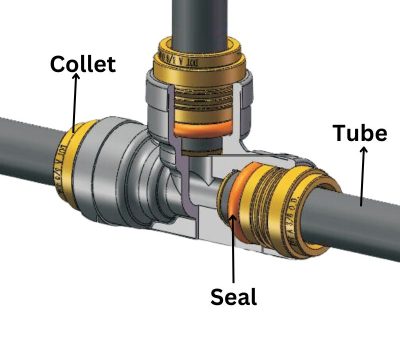

Definition: Push-to-Connect Fittings, also known as quick-connect fittings, are designed for ease of use, allowing for the rapid connection and disconnection of air brake lines without the need for tools. These fittings secure the tubing through a collet and an O-ring, which seals the connection upon insertion of the tube.

Applications: Push-to-Connect Fittings are ideal for applications where quick assembly and disassembly are required, such as in temporary setups or in maintenance sections of air brake systems.

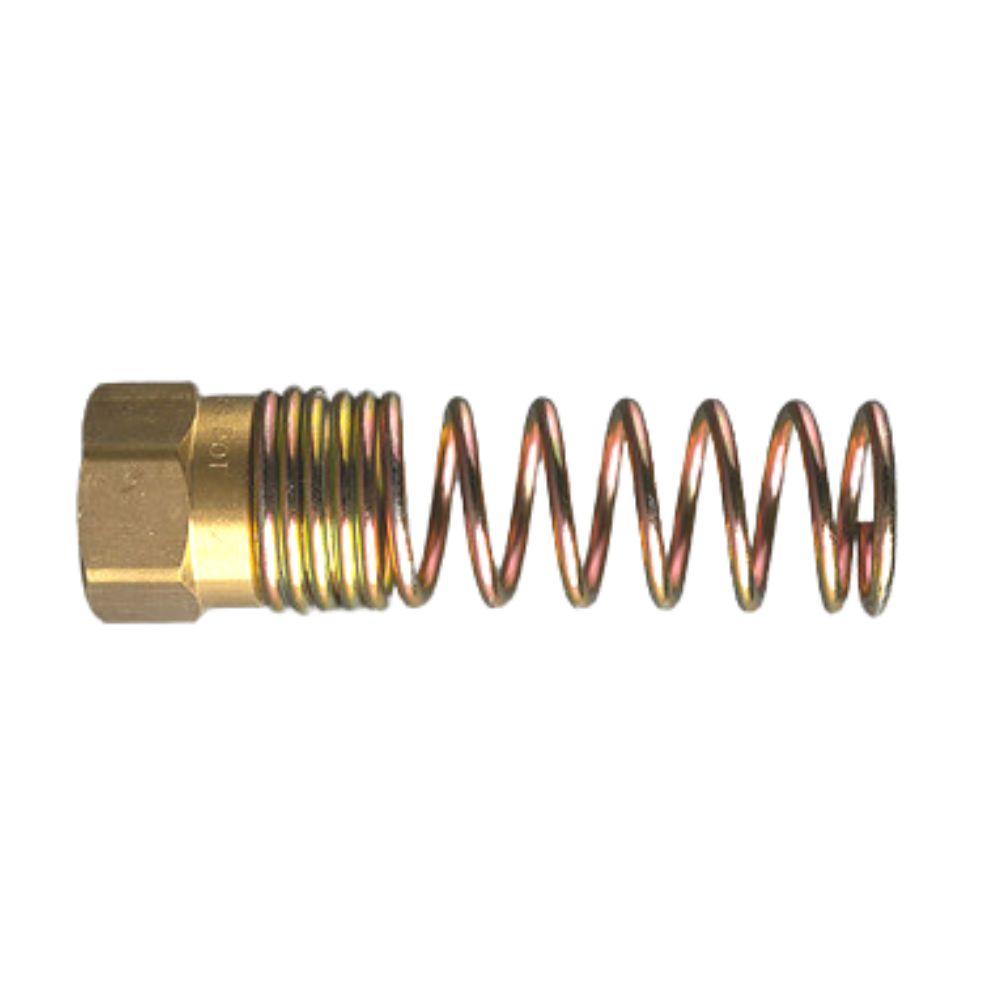

Compression Fittings

Definition: Compression Fittings create a seal through the mechanical tightening of a nut, compressing a ferrule onto a tube, which then seals against the fitting body. This type of fitting is known for its robustness and reliability.

Advantages:

- Durability: Offers a strong, durable connection that is less likely to leak under vibration or temperature changes.

- Versatility: Compatible with a wide range of tubing materials and diameters.

- No Special Tools Required: Can be tightened using standard wrenches, without the need for specialized tools.

Disadvantages:

- Installation Time: Requires more time and effort to install compared to Push-to-Connect Fittings.

- Adjustment Difficulty: Once tightened, they are more difficult to adjust or remove.

Applications: Compression Fittings are suited for permanent installations or in parts of the air brake system that do not require frequent disconnection.

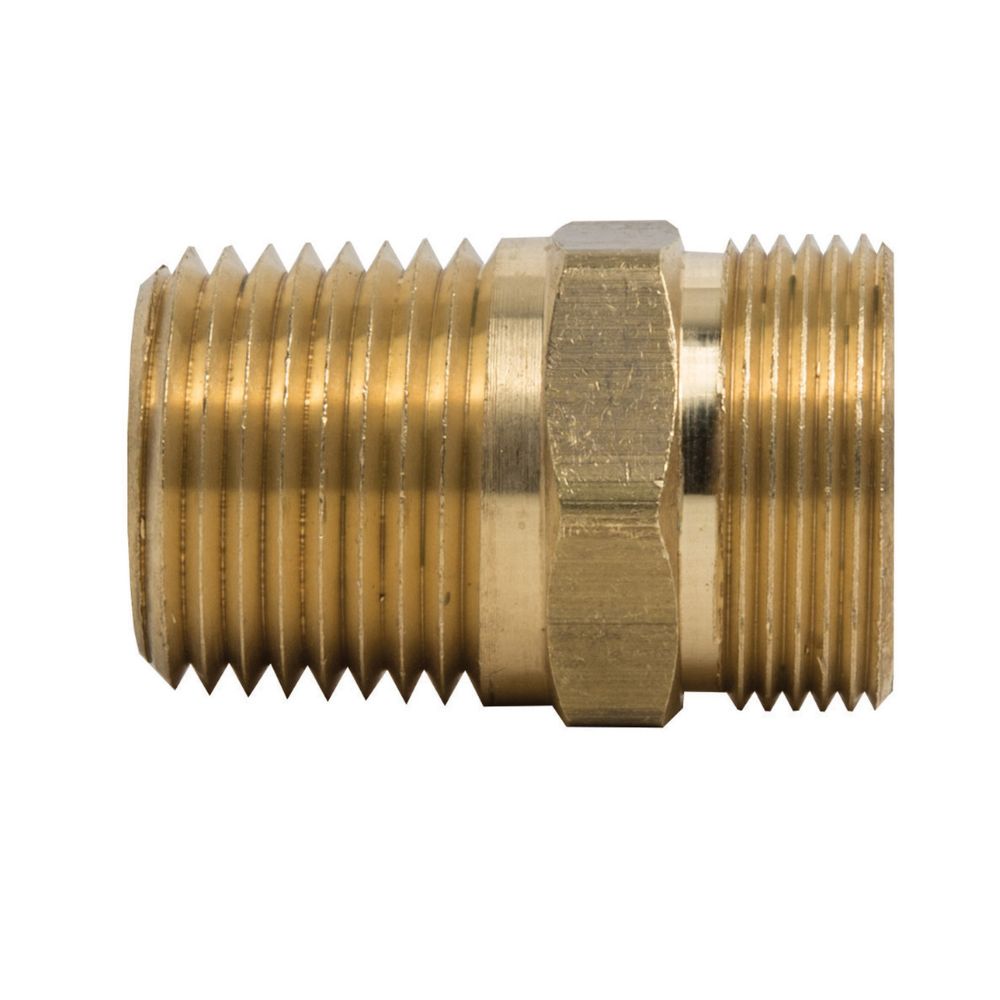

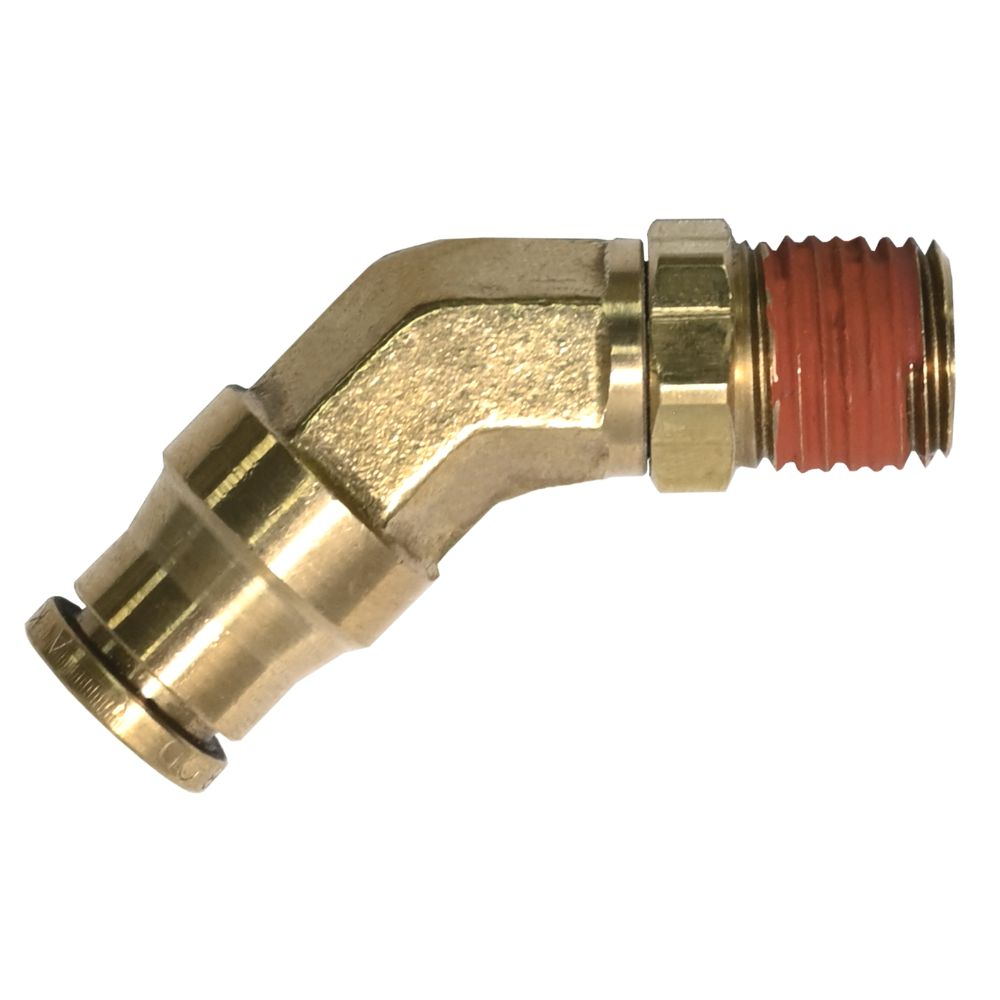

Threaded Fittings

Definition: Threaded Fittings involve screwing two threaded components together to form a sealed connection. They are one of the oldest types of fittings and are available in various thread standards and sizes.

Advantages:

- High Pressure Tolerance: Capable of withstanding high pressure, making them suitable for heavy-duty applications.

- Wide Availability: Available in a variety of sizes and materials, offering flexibility in application.

- Reusability: Can be disconnected and reused without significant loss of integrity.

Disadvantages:

- Risk of Cross-Threading: Incorrect installation can lead to cross-threading, damaging the fitting and compromising the seal.

- Sealant Requirement: Often require thread sealants to ensure a leak-proof connection, adding an extra step in the installation process.

Applications: Threaded Fittings are commonly used in areas of the air brake system where a strong, durable connection is required, and where the fittings are not expected to be frequently disconnected.

Materials of DOT air brake fitting

Brass

Characteristics:

- Corrosion Resistance: Brass is highly resistant to corrosion, making it ideal for use in air brake systems where moisture is present.

- Malleability: It is relatively easy to machine and form, allowing for the production of fittings with precise dimensions and shapes.

- Conductivity: Brass has good thermal and electrical conductivity, though this is generally of less concern for air brake applications.

Advantages:

- Versatility: Suitable for a wide range of temperatures and conditions, brass fittings are versatile in their application.

- Durability: Offers a good balance between strength and ductility, ensuring a long service life under normal conditions.

Applications: Brass fittings are commonly used in air brake systems for their resistance to corrosion and ease of installation.

Stainless Steel

Characteristics:

- Strength: Stainless steel fittings are known for their strength and ability to withstand high pressures, making them suitable for heavy-duty applications.

- Corrosion Resistance: Offers excellent resistance to rust and corrosion, even in harsh environmental conditions.

- Temperature Resistance: Capable of maintaining integrity in both high and low temperatures.

Advantages:

- Longevity: Due to their durability and corrosion resistance, stainless steel fittings have a long lifespan.

- Safety: The strength and reliability of stainless steel reduce the risk of leaks and failures in the air brake system.

Applications: Stainless steel fittings are ideal for use in parts of the air brake system that are exposed to extreme conditions or require high levels of reliability.

Plastic

Characteristics:

- Lightweight: Plastic fittings are significantly lighter than their metal counterparts, contributing to overall vehicle weight reduction.

- Corrosion Resistance: Unlike metal fittings, plastic is inherently resistant to corrosion from chemicals and moisture.

- Cost-Effectiveness: Generally less expensive to produce than metal fittings, making them a cost-effective option for certain applications.

Advantages:

- Versatility: Can be manufactured in a wide range of shapes and sizes, allowing for flexibility in design.

- Insulation: Provides excellent electrical and thermal insulation, which can be beneficial in certain environments.

Applications: Plastic fittings are commonly used in areas of the air brake system where weight and corrosion resistance are priorities, and where the pressure and temperature conditions are within their performance limits.

How D.O.T. Air Brake Fittings Work

Basic Operational Principle of Air Brake Systems

Air brake systems in commercial vehicles operate on a simple yet effective principle: the use of compressed air to apply pressure to the brake pad, which in turn slows down or stops the vehicle. This system consists of several key components, including an air compressor, air reservoir (storage tanks), brake chambers, valves, and pipelines/fittings that connect these components. The compressor generates the compressed air, which is stored in the reservoirs. When the brake pedal is pressed, air is released from the reservoirs and flows through the system, applying pressure to the brake chambers and, consequently, the brakes themselves, slowing down the vehicle.

Pivotal Role of Fittings within Air Brake Systems

Fittings play a crucial role in air brake systems as they connect the various components, ensuring a secure and leak-proof network for the compressed air to travel through. These fittings must be robust and reliable to withstand the pressure and environmental conditions they are exposed to. The integrity of these connections is paramount; any leak or failure can lead to a reduction in braking efficiency or even a complete brake failure, posing serious safety risks.

Distribution and Control of Compressed Air

D.O.T. Air Brake Fittings facilitate the distribution and control of compressed air in several ways:

Secure Connections: They provide tight and secure connections between the pipes and hoses that transport compressed air throughout the brake system. This ensures that air is delivered efficiently to the brake chambers without any leaks.

Directional Control: Certain fittings are designed to direct air flow in specific directions, ensuring that air reaches the appropriate parts of the brake system at the right time.

Pressure Regulation: Some fittings incorporate features that help regulate air pressure within the system, ensuring that the correct amount of pressure is applied to the brakes. This is critical for achieving consistent braking performance under various load and speed conditions.

Quick Disconnection and Reconnection: Quick-connect fittings allow for rapid assembly and disassembly of parts of the air brake system, which is especially useful during maintenance and repair. This ensures that the system can be easily serviced without compromising its integrity or performance.

Installation Guidelines for D.O.T. Air Brake Fittings

Step-by-Step Instructions for Fitting Installation

Installing D.O.T. Air Brake Fittings correctly is crucial for the safety and efficiency of commercial vehicle air brake systems. Here is a step-by-step guide to ensure proper installation, along with tips to avoid common mistakes.

Step-by-Step Installation Process

Preparation:

Ensure all components and fittings are clean and free from debris.

Verify that the fittings and tubes/hoses are compatible in size and type.

Gather necessary tools, such as tubing cutters, wrenches, and Teflon tape (if applicable).

Measuring and Cutting Tubing:

Measure the tubing length required for the installation, allowing a little extra for adjustments.

Cut the tubing cleanly and squarely to ensure a proper fit. Avoid creating burrs or deformities.

Inspecting Components:

Inspect the fittings and tubing for any defects or damage that could compromise the seal or connection.

Inserting Tubing into Push-to-Connect Fittings (if applicable):

Ensure the tubing end is smooth and round.

Push the tubing into the fitting until it is fully seated. A slight tug will ensure it is locked in place.

Tightening Compression and Threaded Fittings:

For compression fittings, insert the tubing and tighten the nut by hand until snug, then use a wrench to give it a final turn.

For threaded fittings, apply Teflon tape or thread sealant to the male threads (if required), then screw the fittings together and tighten with a wrench.

Checking for Leaks:

Once installed, pressurize the system and check all connections for leaks using a soap solution. Bubbles will form at the site of a leak.

Final Inspection:

Ensure all fittings are secure and that the tubing is not kinked or under tension.

Double-check that all tools and materials have been removed from the work area.

Common Installation Mistakes and How to Avoid Them

Over-tightening Fittings: This can cause the fitting to crack or the threads to strip, leading to leaks. To avoid this, tighten fittings to the manufacturer’s specifications and use the correct tools.

Using Damaged Tubing: Cracked, kinked, or deformed tubing can compromise the seal. Always use tubing in good condition and cut it cleanly.

Incorrect Fitting Type: Ensure the fitting type (push-to-connect, compression, threaded) is appropriate for the application and tubing material.

Improper Use of Sealants: When using threaded fittings, apply sealant correctly—avoid over-application and ensure it’s compatible with the system’s air and temperature.

Ignoring Manufacturer’s Instructions: Always follow the manufacturer’s guidelines for installation to ensure compliance and reliability.

Maintenance and Troubleshooting

Regular maintenance and timely troubleshooting of air brake fittings are essential practices that ensure the safety and reliability of commercial vehicle air brake systems. Here are some maintenance tips and guidance on identifying and fixing common issues.

Routine Maintenance Tips

Regular Inspections:

Schedule regular inspections of all air brake system components, including fittings, hoses, and tubing. Look for signs of wear, damage, or corrosion.

Check for Leaks:

Regularly test the system for leaks using a soap solution. Apply the solution to all fittings and connections and look for bubbles that indicate air leaks.

Ensure Tight Connections:

Periodically check the tightness of all fittings. Avoid over-tightening, which can damage fittings or threads.

Cleanliness:

Keep the air brake system clean, especially around fittings and connections. Dirt and grime can cause wear and lead to leaks.

Lubrication:

Apply appropriate lubricants to movable components as per the manufacturer’s recommendations to prevent rust and ensure smooth operation.

Replace Worn Parts:

Replace any worn, damaged, or corroded fittings and tubing. Use only high-quality, D.O.T.-approved replacements.

Troubleshooting Common Issues

Air Leaks:

Identification: Listen for hissing sounds or use a soapy water solution to identify leaks.

Fix: Tighten loose fittings or replace damaged ones. Ensure the tubing is cut straight and fully inserted into push-to-connect fittings.

Reduced Braking Performance:

Identification: Noticeable decrease in braking efficiency or increased stopping distances.

Fix: Check for leaks or blockages in the system. Inspect fittings and tubing for damage or improper installation that may restrict air flow.

Moisture in the System:

Identification: Water coming out of valves or fittings, especially in cold weather, which can lead to freezing and system failure.

Fix: Drain air tanks regularly to remove moisture. Check for failed air dryers or separators that may need replacement or servicing.

Corrosion and Rust:

Identification: Visible rust or corrosion on fittings and connections.

Fix: Replace corroded fittings and consider using corrosion-resistant materials like stainless steel or coated fittings in critical areas.

Vibrations and Noise:

Identification: Excessive vibration or rattling sounds from the air brake system.

Fix: Ensure all fittings are securely tightened. Use appropriate clamps and supports to prevent movement of tubes and hoses.

Conclusion

The D.O.T. Air Brake Accessories certification process emphasizes the importance of rigorous testing and quality assurance. By adhering to the D.O.T. standard, manufacturers protect the lives of drivers and the public by confirming that their products can withstand the rigors of commercial vehicle operation.D.O.T. Air Brake Accessories are the foundation for the operational integrity and safety of commercial vehicles. As the transportation industry continues to evolve and demands for safety and efficiency increase, compliant air brake components will continue to play a vital role.