Hydraulic Compression Fitting Types and Applications

Introduction

Compression fittings are essential components in various industries, offering a reliable and secure method for connecting tubes and pipes. These fittings are integral in systems that require the transport of liquids or gases, providing a tight seal and preventing leaks. Their application spans numerous sectors, including hydraulic systems in manufacturing, fluid delivery in the medical field, fuel lines in aerospace, and water distribution in plumbing. The widespread use of compression fittings underscores their significance in maintaining the functionality and safety of these vital systems. Their adaptability to different materials and pressures makes them indispensable in diverse industrial environments.

History of Compression Fittings

Early Development

The origins of compression fittings are closely linked to the infancy of plumbing and gas systems. In these early stages, the primary goal was to ensure a reliable connection between pipes, often in basic infrastructure such as water supply and rudimentary gas lines.

These initial fittings were simple in design, primarily focusing on functionality over sophistication. They often utilized softer metals like copper or lead, which were more pliable and easier to work with. This choice of materials was crucial as it allowed for manual manipulation to create a sufficient seal, albeit basic by today’s standards.

The simplicity of these early fittings reflected the limited scope of plumbing and gas systems of the time. They were designed to cater to low-pressure applications, mostly in residential or small-scale commercial settings. This era laid the groundwork for more advanced developments in the field of pipe connections.

Technological Evolution

As the demands of industry and technology grew, the limitations of early compression fittings became apparent. This period saw a shift towards more robust and adaptable designs to meet these increasing demands.

Innovations in both the materials used and the engineering processes marked this era. The introduction of harder metals, such as steel and brass, revolutionized the capabilities of these fittings. These materials could endure higher pressures and were more resistant to wear and tear, significantly extending the lifespan and reliability of the connections.

The advancement in engineering precision played a crucial role as well. These included variations in the shape and size of the fittings, catering to a wider range of applications, from industrial machinery to intricate piping systems in large buildings.

This period also witnessed the introduction of synthetic materials like plastics and rubber compounds in the sealing mechanisms. These materials offered improved durability and resistance to various chemicals, expanding the use of compression fittings in more specialized fields such as chemical processing and laboratory setups.

Modern Advancements

Cutting-edge innovations in engineering and materials science have driven the most recent advancements in compression fitting technology. Modern compression fittings are characterized by their ability to withstand extreme conditions. They are designed to endure high pressures, extreme temperatures, and corrosive environments, making them indispensable in sectors like aerospace, deep-sea exploration, and high-tech manufacturing.

The integration of smart technology into compression fittings is a notable modern development. This includes the incorporation of sensors and monitoring systems that can provide real-time data on pressure, flow, and temperature, enhancing the safety and efficiency of fluid and gas transport systems.

Types of Hydraulic Compression Fittings

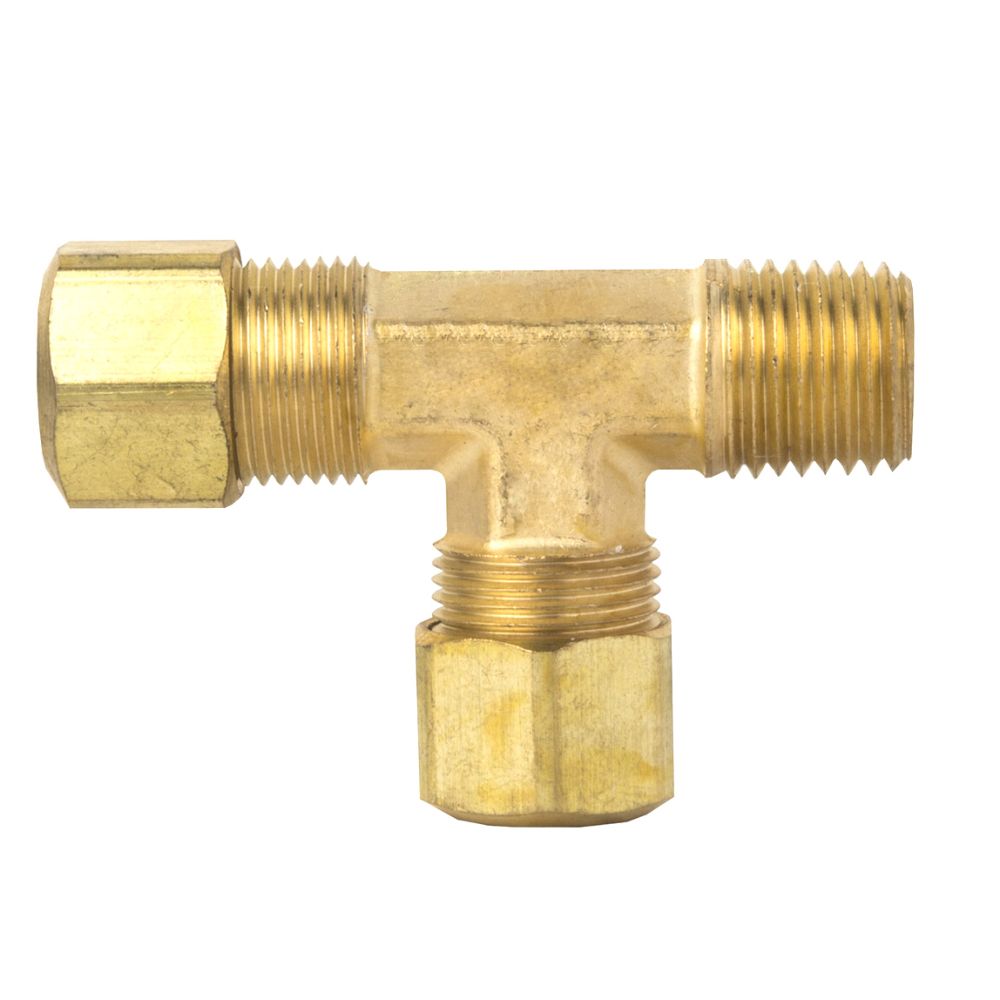

Single Ferrule Fittings

Single ferrule fittings, valued for their straightforward design, use one ferrule to secure and seal the tube. This simplicity translates into fewer parts to manage and an easier installation process, making them an optimal choice in space-constrained environments or situations where quick setup is essential.

Double Ferrule Fittings

These fittings use a dual ferrule system, offering a superior seal and increased grip strength. The front ferrule forms a seal against both the fitting body and the tube, while the back ferrule reinforces the tube grip. This dual action makes them particularly suitable for applications involving high pressure or significant vibration, providing a more secure and stable connection.

Flare Fittings

With their unique design utilizing a flared end of the tubing for sealing, flare fittings are tailored for high-pressure and high-temperature conditions. They are a common choice in systems where a robust seal is paramount, such as in fuel and oil lines.

Other Varieties

This category encompasses specialized types like bite-type fittings, which use a sharp ferrule to grip the tube, and mechanical grip fittings, designed for specific applications where traditional compression fittings may not be suitable. Each type offers distinct advantages and is chosen based on the specific needs of an application.

Material and Design

In the realm of compression fittings, the choice of materials and design considerations are pivotal for their functionality and application range. The most common materials used are:

Brass

This material is widely chosen for its corrosion-resistant properties and flexibility, making it suitable for applications ranging from water supply systems to heating solutions. Brass fittings are appreciated for their malleability, which facilitates easy installation and a reliable seal.

Stainless Steel

With its high resistance to corrosion, heat, and chemical exposure, stainless steel is ideal for more demanding environments. This material is often employed in industrial settings, such as in chemical processing plants or offshore marine operations, where durability and longevity are essential.

In terms of design, two main aspects are considered:

Durability: The design of compression fittings is focused on ensuring that they can withstand various environmental conditions, including pressure fluctuations, temperature extremes, and chemical exposure. This involves precision engineering to ensure that the fittings maintain their integrity over time, even in challenging situations.

Efficiency: Efficiency in compression fittings refers to their ability to maintain a consistent and leak-proof seal. The design is optimized to ensure that the fittings can be easily installed and provide a reliable seal, minimizing potential for leaks, which is crucial in systems where safety and fluid integrity are paramount.

Application in Different Industries

The versatility of compression fittings allows for their widespread use across diverse industries, each with unique requirements and challenges:

Hydraulic Systems

In hydraulic systems, which are fundamental in the construction and manufacturing sectors, compression fittings are used to ensure leak-proof and reliable connections in high-pressure environments. Their role is crucial in maintaining the efficiency and safety of hydraulic machinery, which is often subjected to rigorous operating conditions.

Gas Lines

The safe transport and distribution of gas, whether in urban infrastructure or industrial settings, relies heavily on the integrity of compression fittings. These fittings are critical in preventing leaks, thereby ensuring safety and operational continuity in gas transportation systems.

Medical Equipment

In the healthcare industry, the reliability of compression fittings is paramount, particularly in life-support systems and diagnostic equipment. The precision and quality of these fittings contribute significantly to the overall performance and reliability of medical devices.

Oil and Gas Industry

The oil and gas sector relies on compression fittings for their robustness in handling high-pressure flows. These fittings are key components in oil and gas extraction and transportation systems, where they help in managing the flow and maintaining the integrity of pipelines and drilling equipment.

Installation and Maintenance

Step-by-Step Instructions for Fitting Installation

Preparation: Begin with a thorough inspection of the tubing and fitting components. Ensure that the tubing is cut squarely and deburred, creating a smooth end that will not compromise the fitting’s integrity.

Component Assembly: Assemble the fitting according to the manufacturer’s instructions. This usually involves sliding the nut, followed by the ferrule, onto the tubing.

Insertion: Carefully insert the tubing into the fitting body until it bottoms out. This ensures a proper initial engagement between the tubing and the fitting.

Tightening Technique: Follow the recommended tightening procedure, which typically involves hand-tightening the nut until snug, then applying a specific number of turns with a wrench. This process compresses the ferrule onto the tubing, creating a leak-proof seal.

Final Inspection: After installation, visually inspect the assembly for alignment and proper seating. A correctly installed compression fitting should be securely fastened without any signs of distortion or leakage.

Maintenance Tips for Ensuring Longevity

Regular Inspections: Schedule routine inspections to identify any signs of wear, corrosion, or damage. Early detection of potential issues can significantly reduce the risk of system failures.

Cleaning and Lubrication: Keep the fittings clean from debris and corrosive substances. Apply lubrication where specified by the manufacturer to maintain smooth operation and prevent rust.

Component Replacement: Replace worn or damaged components promptly. Using original parts ensures compatibility and maintains the system’s integrity.

Addressing Common Issues with Troubleshooting

Leak Detection: Regularly check for signs of leaks. If a leak is detected, first ensure the fitting is properly tightened. Over-tightening can damage the fitting and tubing, so adhere to the manufacturer’s specifications.

Corrosion and Wear: Inspect for signs of corrosion or wear, especially in harsh environments. Replace any corroded or worn parts immediately to prevent system degradation.

Improper Sealing: If leaks persist, disassemble the fitting and inspect for improper seating or damage to the tubing and ferrule. Reassemble according to the guidelines, ensuring a clean, debris-free connection.

Environmental Considerations and Sustainability

Eco-Friendly Material Usage

The compression fittings industry, like many others, is increasingly aware of its environmental impact. There is a growing trend towards the use of eco-friendly materials in the manufacturing of compression fittings. These include biodegradable plastics, recycled metals, and other sustainable alternatives that have a lower environmental footprint.

The adoption of these materials is not only beneficial for the environment but also aligns with the global push towards sustainable development. By using materials that are less harmful to the environment, the industry is contributing to the reduction of pollution and the conservation of natural resources.

Sustainable Manufacturing Processes

The industry is also transforming its manufacturing processes to be more energy-efficient and environmentally friendly. This includes optimizing production lines to reduce waste and conserve resources.

Advanced technologies, such as automation and precision engineering, are being employed to minimize errors and excess material usage. This not only enhances efficiency but also significantly reduces the environmental impact of production.

Recycling and Reusability Initiatives

Recycling and reusability are key components of the industry’s approach to environmental sustainability. Many companies are now designing compression fittings that are easier to disassemble and recycle, thereby extending their lifecycle and reducing waste. This not only reduces environmental impact but also offers cost savings for both manufacturers and consumers.

The promotion of reusable fittings, which can be easily adjusted or reconfigured for different applications, is also gaining traction. This approach not only conserves resources but also provides flexibility and cost-effectiveness for users.

Contributing to a Sustainable Future

The compression fittings industry’s commitment to environmental sustainability is part of a broader movement within the industrial sector to address global environmental challenges.

Conclusion

In conclusion, this comprehensive overview of compression fittings has delved into various types, their essential role in numerous industries, and the specific considerations for their material and design. We’ve covered the critical aspects of installation, maintenance, and the adherence to necessary regulations and standards. It’s imperative for professionals in this field to keep abreast of the latest advancements and continue innovating in their application of compression fittings. This ongoing commitment to knowledge and innovation is key to maintaining safety, efficiency, and reliability in their use across diverse industrial applications.