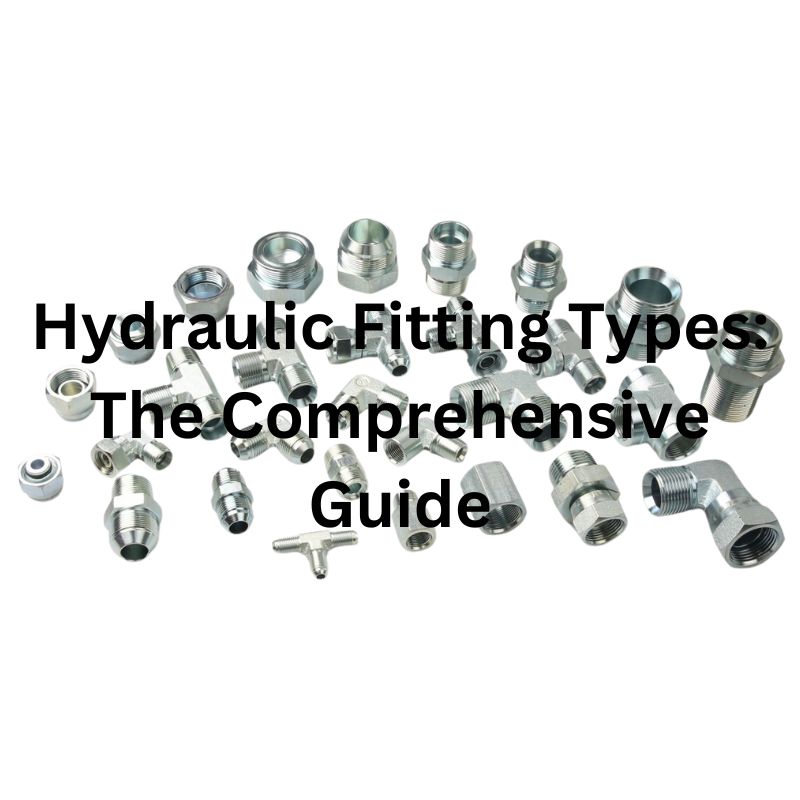

The Comprehensive Guide to Hydraulic Fitting Types

Our Blog

Comprehensive Guide

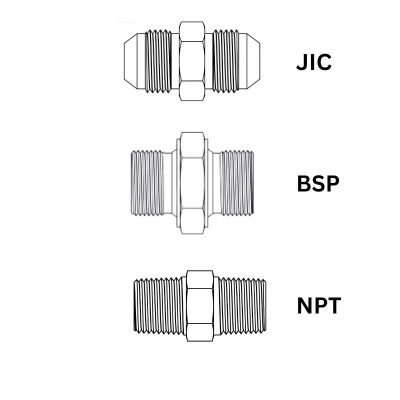

A comprehensive guide to hydraulic fitting types can help you learn more about threads such as JIC, BSP, SAE, JIS and NPT. This guide provides clear and practical advice to help you choose the right fitting for your hydraulic system. This guide all ensures that you have the knowledge you need to make informed decisions and maintain efficient, reliable operation.

Chapter 10

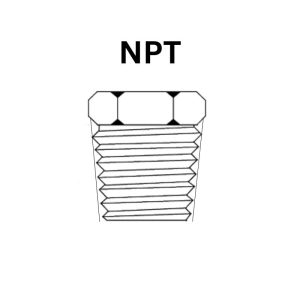

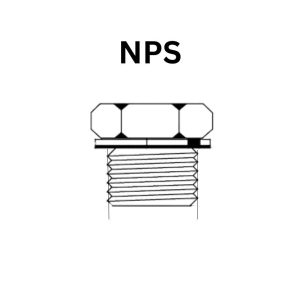

Pipe Thread vs Straight Thread Hydraulic Fittings

Chapter 11

JIC vs NPT Fittings: The Ultimate Guide

Chapter 12

SAE vs JIC Hydraulic Fitting: What's the Difference

Chapter 13

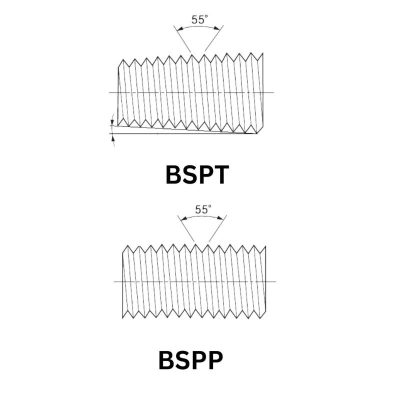

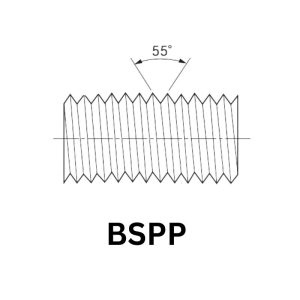

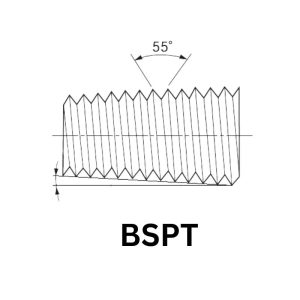

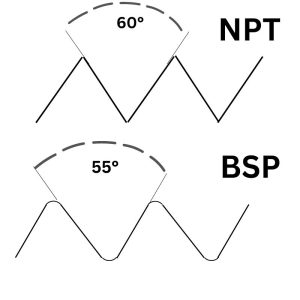

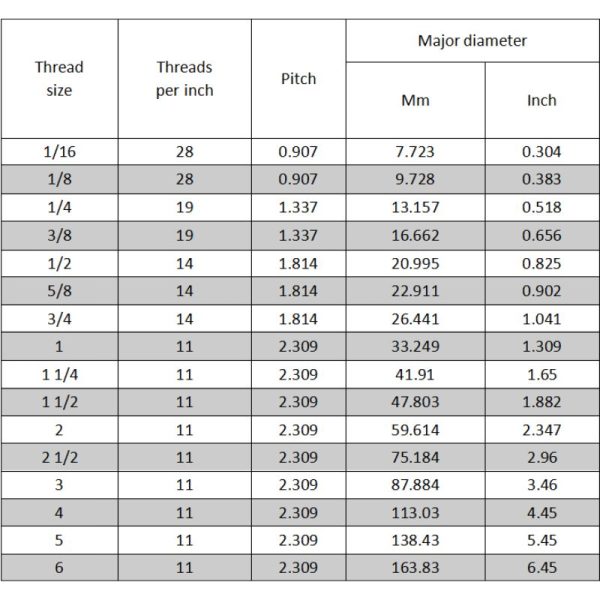

BSP VS NPT Threads:What are the Differences?

Chapter 14

UNC vs UNF Fittings: What is the Difference?

Your Questions?

Confused about the content of the article? Have any suggestions? Contact us and Topa will get back to you as soon as possible!