Currently, hydraulic systems exist in many applications, so it is vital to understand the knowledge of hydraulic fittings. Now you can follow us and learn more about hydraulic fittings!

Hydraulic fittings are components that act as connections. They connect the components of a hydraulic system to form a strong seal and ensure the proper functioning of the hydraulic system. Hydraulic fittings allow the hydraulic fluid to combine or diver. In some hydraulic systems, special hydraulic fittings can change the direction of the fluid. Also, hydraulic fittings like plugs can be used as the end of a hydraulic piping system to stop fluid leaks.

Usually, hydraulic fittings are metal products that can withstand different pressure specifications. Common fittings vary in corrosion resistance, wear resistance, and sealing properties depending on the materials. Most fittings are made according to international standards, so they can be adapted to fit the needs of all applications.

Hydraulic fitting is a collection. There are many sub-categories of hydraulic fittings, which differ in appearance, function, and operating conditions.

One end of a hydraulic hose fitting is the threaded end and the other end is the hose connection end. The threaded end is divided into a male and a female end, the male end are external threads and can be connected with the female end. The hose end is inserted into the corresponding size of the hose and can be fixed with the help of clamps.

Both ends of the adapter are threaded ports. The hydraulic adapter has male-to-male, male-to-female, and female-to-female types. Both sides of the adapter can be the same threads or different threads.

Tee fitting has three threaded ends and a cross fitting has four threaded ends. Tee and cross fittings are used to divide the fluid into different directions, tee fittings can divide the fluid into two directions and the crosses can divide the fluid into three directions.

Bulkhead fittings are used to pass through a fixed wall or plate to connect the fitting to other components. They are usually used in bulkheads or tanks.

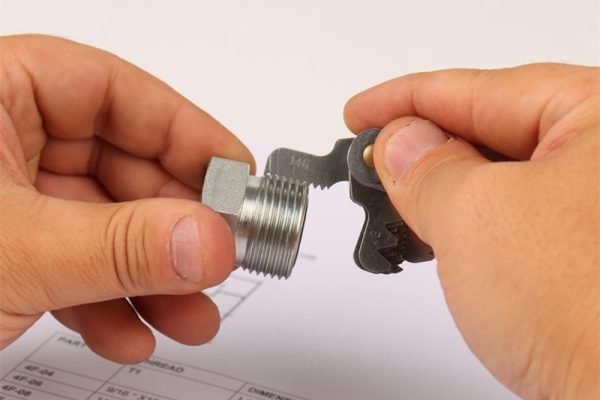

A reusable (field-attachable) hydraulic fitting has a threaded end on one end, a hose end with a reusable sleeve on the other. These fittings are easy to disassemble and install. And can be removed or installed multiple times.

One-piece fittings are different from reusable fittings because they are one-piece fittings with non-removable sleeves. These fittings are commonly available in the 43 series, 71 series, and HY series.

A plug is a male threaded fitting and a cap is a female threaded fitting. They are both used at the end of a pipe system to stop fluid leakage or contamination.

Flange fittings can be used in high-pressure environments and are bolted together to form a seal. There are two main types of flange fittings: SAE Code 61 and Code 62 series.

The Ferrule is a cylindrical metal fitting used with hydraulic hoses to secure hoses and hose fittings.

Topa can offer different types of hydraulic hose fittings and hydraulic adapters, please contact us!

Every hydraulic fitting has threads, the most common threads used internationally are as follows:

Threads | Types |

JIC(Joint Industrial Council) | Parallel |

NPTF(National Pipe Tapered Fuel) | Tapered |

NPSM(National Pipe Straight Mechanical) | Tapered |

BSPP (British Standard Pipe Parallel) | Parallel |

BSPT(British Standard Pipeapered) | Tapered |

JIS(Japanese Industrial Standards) | Parallel |

Metric/DIN | Tapered/Parallel |

In the hydraulic environment, metal fittings are the most common choice. In hydraulic environments, metal hydraulic fittings are the most common.

Depending on the acid or alkaline environment and pressure range, the type of metal fitting varies.

The most common metal types used in hydraulic systems are carbon steel, stainless steel, brass, and aluminum.

The most common metal used in hydraulic systems is carbon steel. Carbon steel is made of carbon and steel and can be used in many applications. Carbon steel connectors are less resistant to corrosion but are easy to process, resistant to pressure, and cost-effective.

In some ways, stainless steel is the most superior metal. Stainless steel fittings are resistant to corrosion, pressure resistance, and abrasion resistance, durable and strong, but can be relatively expensive. Stainless steel fittings are available in many standards, with 304 and 316 being the most popular choices.

Brass consists of copper and zinc, which is a special alloy. Brass in general is highly resistant to corrosion and is highly machinable. Brass fittings and tubing are recommended for applications such as automotive, domestic, and industrial.

Aluminum fittings are moderately corrosion-resistant, lightweight, and suitable for low-pressure environments. Aluminum brake fittings are more commonly used in automobiles and aircraft.

ISO: ISO (International Organization for Standardization) is a world-class standard that covers many aspects of hydraulic fitting testing. These standards specify the performance and dimensional requirements for hose fittings, flanges, quick fittings, etc.

SAE: SAE (Society of Automotive Engineers) specifies standards for hydraulic fittings and hydraulic hoses to ensure that these fittings are dimensionally correct and can withstand the appropriate operating pressures. The most common standards for fittings and hoses are SAEJ512, SAEJ516, and SAEJ514.

DIN: DIN (Deutsches Institut für Normung) is a German standard that defines the thread, dimensional, and operational requirements for hydraulic hose fittings, compression fittings, and adapters.

Some famous brands have developed their own standards, such as Parker, Gates, Eaton, etc. Topa can do all kinds of standards, please contact us and tell us your needs.

Hydraulic fittings can be applied in a wide range of applications. As long as there are hydraulic systems in the applications, there is a definite need for hydraulic fittings. Different sizes, materials, and types of fittings are used in different environments. In general, these areas will require the use of fittings:

Agriculture: Tractors, harvesters, and irrigation systems all need hydraulic adapters.

Industry: Hydraulic systems are present in most equipment in industrial applications, so hydraulic fittings are present to keep the system running properly.

Construction: Excavators, bulldozers, and other large machinery and equipment require high-quality hydraulic fittings.

Oil and gas: Transporting and storing oil and gas requires hydraulic fittings that do not create leaks.

Marine: Marine transportation or offshore oil wells require corrosion-resistant, strong-sealing hydraulic fittings.

Transportation: Many industries will need to transport materials, so hydraulic piping can ensure the safe transportation of fluids under pressure.

Automotive: There are specific standard fittings for brake systems and fuel systems in automobiles. These fittings ensure the proper operation of the system.

Topa can offer security service and transportation to all customers, so contact us!

The hydraulic system can only maintain normal operation if the correct hydraulic fittings are selected. Therefore, the selection of the right hydraulic fittings should be considered from the following aspects:

The right size corresponds to the right installation for the right application.For example, imperial sizes are 1/8′, 3/8′, and 1/2′. Metric sizes are M8*1.0, M10*1.0, and M22*1.5, etc. American sizes are 1/8, 1 1/4, and 2, etc. When selecting a fitting, choose the fitting size carefully.

Hydraulic fittings size chart

No. | 02 | 04 | 05 | 06 | 08 | 10 | 12 | 16 | 20 | 24 | 32 |

BSPP | G1/8″×28 | G1/4″×19 |

| G3/8″×19 | G1/2″×14 | G5/8″×14 | G3/4″×14 | G1″×11 | G1.1/4″×11 | G1.1/2″×11 | G2″×11 |

BSPT | R1/8″×28 | R1/4″×19 |

| R3/8″×19 | R1/2″×14 |

| R3/4″×14 | R1″×11 | R1.1/4″×11 | R1.1/2″×11 | R2″×11 |

NPT | Z1/8″×27 | Z1/4″×18 |

| Z3/8″×18 | Z1/2″×14 |

| Z3/4″×14 | Z1″×11.5 | Z1.1/4″×11.5 | Z1.1/2″×11.5 | Z2″×11.5 |

JIC |

| 7/16″×20 | 1/2″×20 | 9/16″×18 | 3/4″×16 | 7/8″×14 | 1.1/16″×12 | 1.5/16″×12 | 1.5/8″×12 | 1.7/8″×12 | 2.1/2″×20 |

ORFS |

| 9/16″×18 |

| 11/16″×16 | 13/16″×16 | 1″ ×14 | 1.3/16″×12 | 1.7/16″×12 | 1.11/16″×12 | 2″×12 |

|

SAE |

|

|

| 5/8″×18 |

|

| 1.1/16″×14 |

|

|

|

|

Flange |

|

|

|

| 1/2″ | 5/8″ | 3/4″ | 1″ | 1.1/4″ | 1.1/2″ | 2″ |

Push in |

| 04 |

| 06 | 08 |

| 12 | 16 | 20 | 24 | 32 |

Note: Metric threads are marked according to the outside diameter of the thread, and tube straight pipe is marked according to the outside diameter of the straight pipe. | |||||||||||

In hydraulic systems, there are differences in ambient temperatures. And the operating temperature range of hydraulic fittings should be selected according to the ambient temperature.

The application environment of a hydraulic fitting determines the type of fitting. There are detailed differences in the types of fittings used for agricultural, industrial, marine, transportation, and automotive applications.

The media present in a hydraulic system can cause differences in pH, temperature, pressure, and friction, so the fitting should be compatible with the media to ensure no leaks or contamination.

Different environments will require different materials for hydraulic fittings. Also, the cost of the fittings differs from material to material.

The rated pressure of the hydraulic fitting should be higher than the system pressure to ensure that the hydraulic system will not leak or be damaged.

Each hydraulic fitting has its own characteristics, but some of them are not very obvious, so how to distinguish them?

First, observe the shape.

If one end of the fitting is a tube and the other end is threaded, then this is a hose fitting; if both fitting ends are threaded, then it is a hydraulic adapter. A fitting with three ports is a tee, and one with four is a cross fitting; The body of the swivel fitting can be rotated in all directions, and the sleeve of the reusable fitting is removable, while the one-piece fitting is a whole part.

Next, use a thread gauge.

Some threads can be observed visually as straight or tapered threads. For example, BSPT and NPT are tapered threads. BSPP and UN/UNF are straight threads. If it is difficult to observe, use the corresponding thread gauge to check.

Then you can use a pitch gauge to measure the pitch.

Use vernier calipers to determine the size of the fitting, or the inside(I.D) and outside diameter (O.D)of the fitting.

If you really can’t identify what type of fitting you have, check your supplier’s data, or contact us directly!

Hydraulic fittings are divided into two major categories, hydraulic hose fittings, and hydraulic adapters. The two types of fittings differ in some details of the tools used and the installation process.

Adjustable wrench: It can be adjusted according to the size of the fitting or hexagonal nut.

Cutting tool: used to cut the hose, tube, or pipe.

Sealant: Prepare sealing measures in advance if needed.

Protective equipment: Prepare gloves or goggles to protect yourself.

Hose fitting

Inspection: Check the appearance of the fitting before installation to make sure the threads are free of burrs, rust, and breakage.

Cutting: Cut the hose to the proper length.

Installation: Install the hose end of the fitting into the hose and tighten the nut to form a hose assembly. For crimp fittings, use a crimper to secure the fitting.

Test: Test for leaks in the hydraulic system.

Hydraulic adapter

Inspection: Check that there are no scratches, burrs, or breaks on the adapter.

Installation: You can apply a little lubrication to the adapter, use a wrench, and screw the fitting into the installation position. If the fitting has an O-ring seal, make sure the O-ring is not broken. And make sure the O-ring is installed in the correct position.

Testing: Test the assembly to make sure there are no leaks in the hydraulic system.

In addition, there are some special fittings: welded hydraulic fittings. These types of hydraulic fittings require professional installers to weld them.

If you have any installation questions, contact us!

The factory will strictly follow each step of the process when producing hydraulic fittings to make the best quality fittings.

Raw material purchase – Raw material processing – CNC Lathe processing – Surface treatment – Inspection

Hydraulic fittings are generally processed using hot forging, which greatly improves the strength and toughness of the fittings.

In CNC lathe processing, the fitting will go through several steps, including punching, profile processing, and thread processing.

After the fitting is processed, it needs to undergo surface treatment to improve the aesthetics of the fitting. Common treatments include galvanizing, pickling, grinding, polishing, etc.

All fittings of Topa are inspected several times for appearance, threads, and quality. Topa factory uses salt spray testers, pulse testers, and other instruments for this purpose.

Some hydraulic fittings can be sealed directly by the metal surface, or by O-rings. Except for this type of fittings, others need some external help.

Teflon tape: can be wrapped directly around the threads to create a seal during installation; NPT threads often require tape to create seals.

Sealant: Loctite 5452 liquid thread sealant can be applied directly to the threads. When the fitting is used in a hydraulic system, it can directly seal the gap between the fitting and the component connection.

Hydraulic fittings are an integral component of the hydraulic system. Therefore, it is crucial for everyone to learn about all aspects of hydraulic fittings.

Topa is a professional hydraulic fitting factory and industry, we know a lot about hydraulic fitting products, if you still have questions, please contact us!

Find out more about Topa Blog and learn more about specialized hydraulic fittings.