Telescopic Hydraulic Cylinder Manufacturers

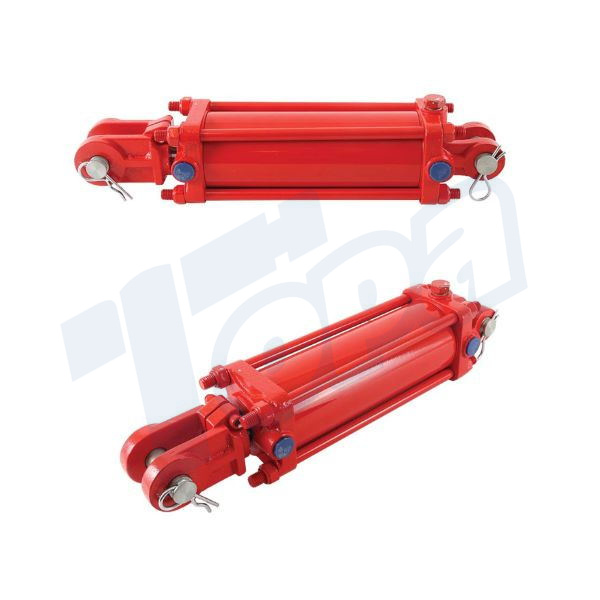

Telescopic hydraulic cylinders combine a variety of features and benefits that are invaluable in many industrial applications. Hydraulic telescopic cylinders are available in a variety of types to meet different applications and operational requirements.

The most common classifications include Single-Acting, Double-Acting, and Rod types. Each type has its unique advantages and is designed to meet specific needs, whether it’s for lifting, tilting, or pushing and pulling actions. Understanding these classifications can help you select the most appropriate telescopic hydraulic cylinder for your specific application, ensuring efficiency and reliability.

Topa is one of the best telescopic hydraulic cylinder manufacturers, so contact Topa for more information and your hydraulic cylinders needs!

Designed for dump trucks, this inverted cylinder offers a unique configuration that allows for a lower mounting height and increased dumping angles.

Specifically engineered for dump trucks, this cylinder provides powerful lifting and tilting capabilities with its multi-stage extension.

This cylinder is equipped with eye mounts for easy attachment and is commonly used in front-end loaders for lifting and tilting actions.

Ideal for applications requiring extension through hydraulic pressure and retraction via gravity, commonly used in dump trailers.

Designed for telescopic loaders, this cylinder offers extended reach and high load capacity, making it ideal for material handling tasks.

This cylinder features a single ear mounting option and is used in applications where lateral space is limited but high lifting force is required.

These cylinders are used in tipper trailers and offer the ability to tilt the trailer bed at steep angles for efficient unloading.

Positioned under the body of the vehicle, this cylinder is used for lifting applications where space is limited.

Telescopic Hydraulic Cylinder

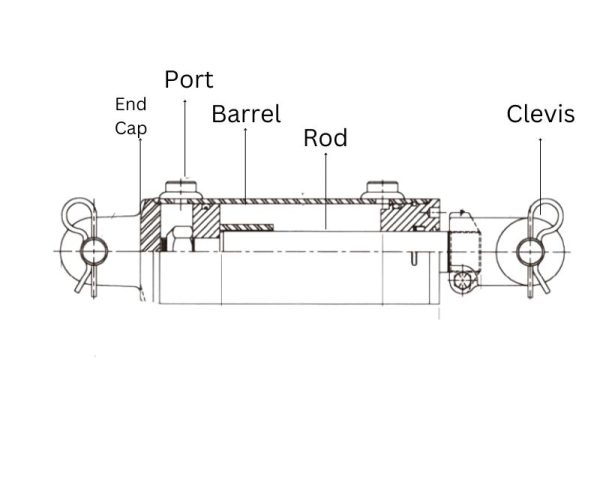

When choosing a hydraulic cylinder for your operation, understanding the features of telescopic hydraulic cylinders can help you make a better choice. These cylinders have special design features that make them very popular in a variety of applications. Here are some of the key features that set them apart:

Features

Telescopic hydraulic cylinders have a multi-stage retraction capability that provides a greater range of expansion and contraction than standard hydraulic cylinders. This is especially useful in space-constrained applications, as their compact design maximizes space when retracted. Designed for high load capacities, these cylinders are rugged and ideal for heavy-duty tasks. Variable stroke lengths add flexibility, making them suitable for a wide range of applications.

Functionally, they excel at lifting heavy loads vertically, pulling and pushing efficiently thanks to their multi-stage design, and can also be used for inclined applications such as tipping trucks. All of these features make telescopic hydraulic cylinders an invaluable asset to a wide range of industries.

Applications

Construction Industry: In cranes and earth-moving equipment, these cylinders provide the necessary lifting and tilting actions.

Transportation: They are commonly found in vehicles like garbage trucks and dump trucks where space is limited, and heavy lifting is required.

Agriculture: Used in modern farming equipment like tractors and harvesters for various functions including lifting and tilting.

Manufacturing: In factories, these cylinders are used in automated assembly lines and material handling systems.

Marine Applications: Used in applications like ship lifts and hoists.

Mining: Employed in heavy machinery used for digging and transporting materials.

Waste Management: In recycling plants, these cylinders are used for compacting waste materials.

Advantages

Space Efficiency: One of the most significant advantages is the compact design when fully retracted, making them ideal for applications where space is a premium.

High Load Capacity: These cylinders are designed to handle heavy loads efficiently, making them suitable for heavy-duty applications.

Versatility: The ability to vary the stroke length means these cylinders can be customized for a wide range of applications, from construction to transportation.

Operational Speed: The multi-stage extension and retraction capabilities allow for quicker operations, which is crucial in time-sensitive tasks.

Cost-Effectiveness: While the initial investment might be higher than standard cylinders, the long-term benefits in terms of durability and efficiency make them a cost-effective choice.

Topa Hydraulic Cylinder Video

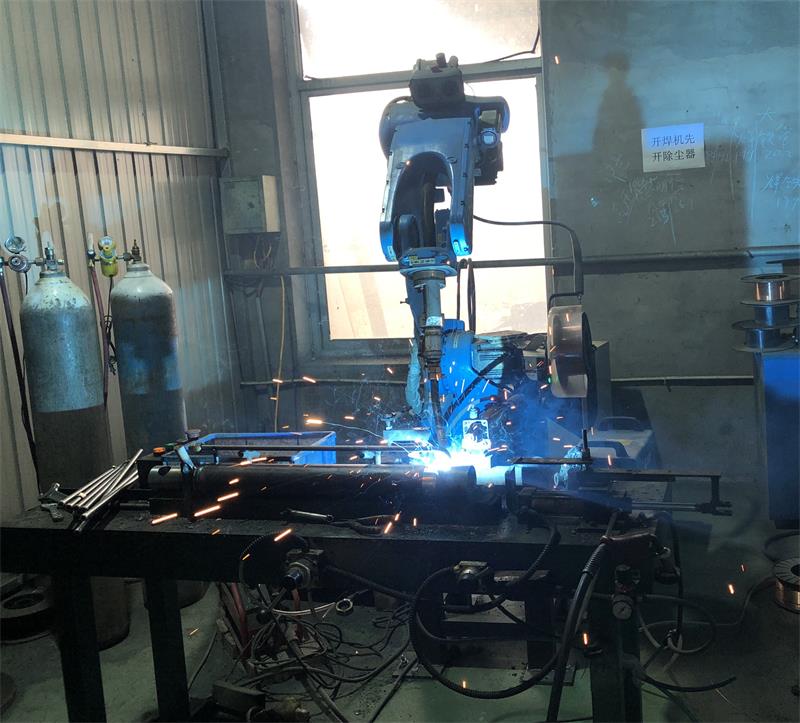

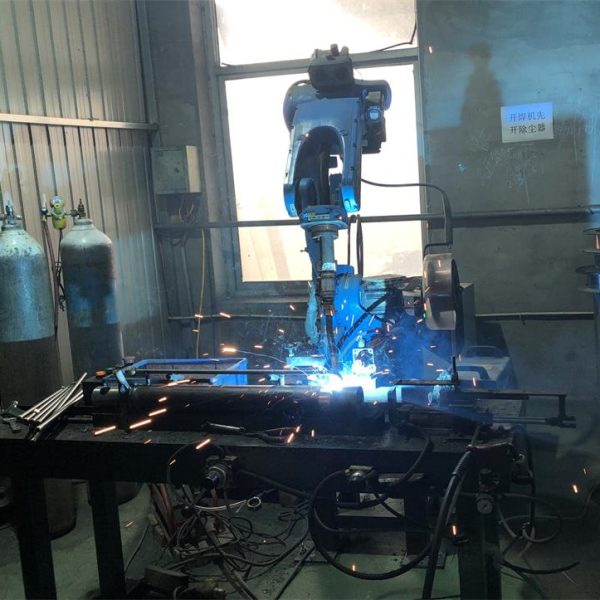

At Topa, the manufacturing process of our hydraulic cylinders is meticulously planned and executed to ensure the highest quality and performance.

The journey begins with the sourcing of premium raw materials, which are then subjected to rigorous quality checks. Our state-of-the-art manufacturing facility employs advanced machining techniques, to achieve precision and durability in each component.

Once the components are assembled, the cylinders undergo a series of tests, including pressure tests, leak tests, and performance evaluations, to confirm their reliability and efficiency. Our team of skilled professionals closely monitors each step, applying their expertise to troubleshoot and optimize the process. With a focus on both quality and efficiency, Topa’s manufacturing process is designed to meet the diverse needs of our clients, offering hydraulic cylinders that are not just robust and reliable, but also cost-effective.

Why Choose Topa?

At Topa, we specialize in providing high-quality telescopic hydraulic cylinders that stand out in the market for several reasons:

Quality Assurance: Our cylinders are manufactured under stringent quality control measures, ensuring durability and long-lasting performance.

Customization: We offer customized solutions to meet the specific needs of your applications, whether it’s for construction, transportation, or industrial machinery.

High Load Capacity: Our telescopic cylinders are designed to handle heavy loads efficiently, making them ideal for heavy-duty tasks.

Cost-Performance Ratio: Sourced and manufactured in China, our products offer a higher cost-performance ratio, providing both quality and affordability.

Expert Support: Our team of skilled professionals is always ready to provide technical support and guidance, ensuring that you get the most out of your hydraulic systems.

Quick Turnaround: Our efficient manufacturing processes and logistics ensure quick delivery, helping you meet your project timelines.

By choosing Topa, you’re investing in a solution that brings value, efficiency, and reliability to your operations. Feel free to reach out for more specialized solutions tailored to your needs.