Description

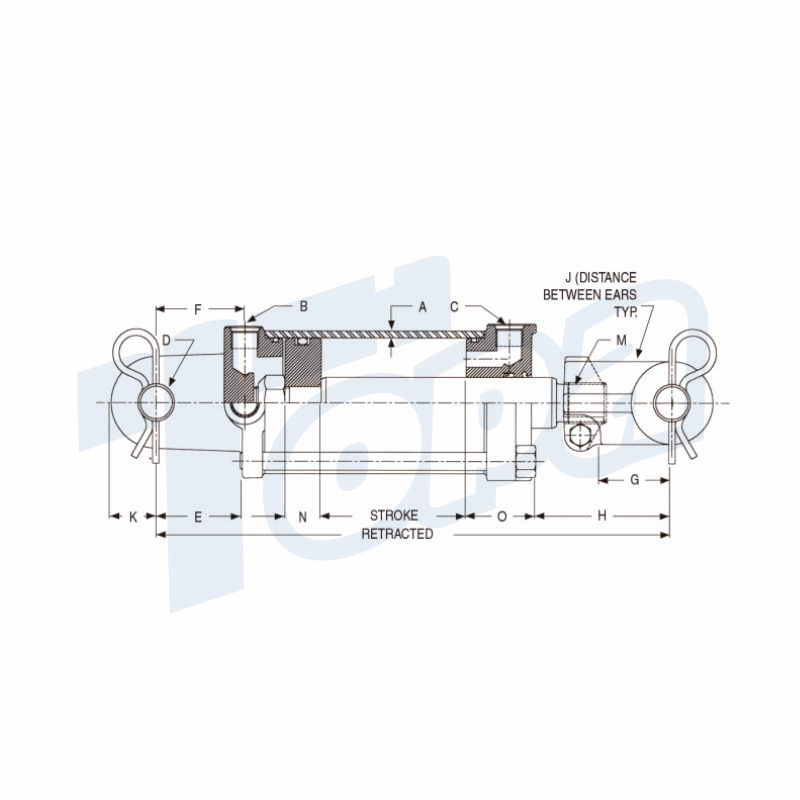

TRH | MFGR NO. | BO RE | STR OKE | ROD DIA. | RE- TRACT DIMEN. | A | B/C PORT SIZE | D | E | F | G | H | J | K | M | N | O |

TRH-2004 | 8404 | 2 | 4 | 1 | 141/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 5/16 | 2 7/16 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1-14 | 7/8 | 2 1/4 |

TRH-2006 | 8406 | 2 | 6 | 1 | 161/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 5/16 | 2 7/16 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1-14 | 7/8 | 2 1/4 |

TRH-2008 | 8408 | 2 | 8 | 1 | 201/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 5/16 | 2 7/16 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1-14 | 7/8 | 2 1/4 |

TRH-2010 | 8410 | 2 | 10 | 1 | 201/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 5/16 | 2 7/16 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1-14 | 7/8 | 2 1/4 |

TRH-2012 | 9012 | 2 | 12 | 1 1/8 | 22 1/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1 1/8-12 | 7/8 | 2 3/8 |

TRH-2014 | 9014 | 2 | 14 | 1 1/8 | 24 1/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1 1/8-12 | 7/8 | 2 3/8 |

TRH-2016A | 9016 | 2 | 16 | 1 1/8 | 31 1/2 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 81/2 | 1.06 | 15/16 | 1 1/8-12 | 7/8 | 2 3/8 |

TRH-2018 | 9018 | 2 | 18 | 1 1/8 | 28 1/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1 1/8-12 | 7/8 | 2 3/8 |

TRH-2020 | 9020 | 2 | 20 | 1 1/8 | 301/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1 1/8-12 | 7/8 | 2 3/8 |

TRH-2024 | 9024 | 2 | 24 | 1 1/8 | 341/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1 1/8-12 | 7/8 | 2 3/8 |

TRH-2030 | 9030 | 2 | 30 | 1 1/8 | 401/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1 1/8-12 | 7/8 | 2 3/8 |

TRH-2506 | 7006 | 2 1/2 | 6 | 1 1/8 | 161/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 2 3/8 |

TRH-2508 | 9108 | 2 1/2 | 8 | 1 1/4 | 201/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 51/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 2 3/8 |

TRH-2510 | 9110 | 2 1/2 | 10 | 1 1/4 | 201/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 2 3/8 |

TRH-2512 | 9112 | 2 1/2 | 12 | 1 1/4 | 221/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 2 3/8 |

TRH-2514 | 9114 | 2 1/2 | 14 | 1 1/4 | 241/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 2 3/8 |

TRH-2516 | 9116 | 2 1/2 | 16 | 1 1/4 | 31 1/2 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 81/2 | 1.06 | 15/16 | 1 1/8-12 | 1 | 2 3/8 |

TRH-2518 | 9118 | 2 1/2 | 18 | 1 1/4 | 281/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 2 3/8 |

TRH-2520 | 9120 | 2 1/2 | 20 | 1 1/4 | 301/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 2 3/8 |

TRH-2524 | 9124 | 2 1/2 | 24 | 1 1/4 | 341/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 2 3/8 |

TRH-2530 | 9130 | 21/2 | 30 | 1 1/4 | 401/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 3/8 | 1 13/16 | 31/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 2 3/8 |

TRH-3006 | 7106 | 3 | 6 | 1 1/8 | 161/4 | 1/8 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 7/16 | 1 13/16 | 3 3/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 1 15/16 |

TRH-3008 | 9208 | 3 | 8 | 1 3/8 | 201/4 | 3/16 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 7/16 | 1 13/16 | 5 3/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 1 15/16 |

TRH-3010 | 9210 | 3 | 10 | 1 3/8 | 201/4 | 3/16 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 7/16 | 1 13/16 | 3 3/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 1 15/16 |

TRH-3012 | 9212 | 3 | 12 | 1 3/8 | 22 1/4 | 3/16 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 7/16 | 1 13/16 | 3 3/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 1 15/16 |

TRH-3014 | 9214 | 3 | 14 | 1 3/8 | 241/4 | 3/16 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 7/16 | 1 13/16 | 3 3/16 | 1.06 | 15/16 | 1 1/8-12 | 1 | 1 15/16 |

TRH-3016 | 10616 | 3 | 16 | 1 3/8 | 261/4 | 3/16 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 7/16 | 1 13/16 | 3 3/4 | 1.06 | 1 1/4 | 1 1/8-12 | 1 | 1 15/16 |

TRH-3016A | 9216 | 3 | 16 | 1 3/8 | 31 1/2 | 3/16 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 7/16 | 1 13/16 | 9 | 1.06 | 15/16 | 1 1/8-12 | 1 | 1 15/16 |

TRH-3018 | 9218 | 3 | 18 | 1 3/8 | 281/4 | 3/16 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 7/16 | 1 13/16 | 3 3/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 1 15/16 |

TRH-3020 | 9220 | 3 | 20 | 1 3/8 | 301/4 | 3/16 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 7/16 | 1 13/16 | 3 3/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 1 15/16 |

TRH-3024 | 9224 | 3 | 24 | 1 3/8 | 341/4 | 3/16 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 7/16 | 1 13/16 | 3 3/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 1 15/16 |

TRH-3030 | 9230 | 3 | 30 | 1 3/8 | 401/4 | 3/16 | 3/4-16 SAE | 1.015 | 2 7/16 | 2 7/16 | 1 13/16 | 3 3/4 | 1.06 | 15/16 | 1 1/8-12 | 1 | 1 15/16 |

TRH- Heavy Duty Tie rod Hydraulic Cylinders

The heavy duty Tie Rod Hydraulic Cylinders are specially designed for the toughest tasks. They like the strong backbone of heavy machinery, capable of handling massive loads with ease.

Topa’s global presence allows us to serve clients not only in the United States, Canada, Australia, and Europe but also in regions like Afghanistan, Algeria, India, Indonesia, Thailand, South Korea, and more. We are your reliable partner, no matter where your operations are based.

If you have any specific inquiries or require further assistance, please do not hesitate to reach out. We are here to support your hydraulic cylinder products and component needs.

Advantages of Hydraulic Cylinders From Topa

To make sure it lasts, Topa uses top-quality materials. These materials resist wear, rust, and damage, so your cylinder keeps working, even under harsh conditions.

Our Tie rod Hydraulic Cylinders are all about precision. Each part is carefully made to fit perfectly, reducing leaks and ensuring it performs at its best.

Topa Heavy Duty Hydraulic Cylinder is all about precision. Each part is carefully made to fit perfectly, reducing leaks and ensuring it performs at its best.

In summary, our heavy hydraulic cylinder is the powerhouse you need for the toughest jobs. Whether it’s construction, mining, or any heavy-duty work, it’s up to the task. If you have questions or need more information, please reach out. We’re here to support your hydraulic product needs.