Description

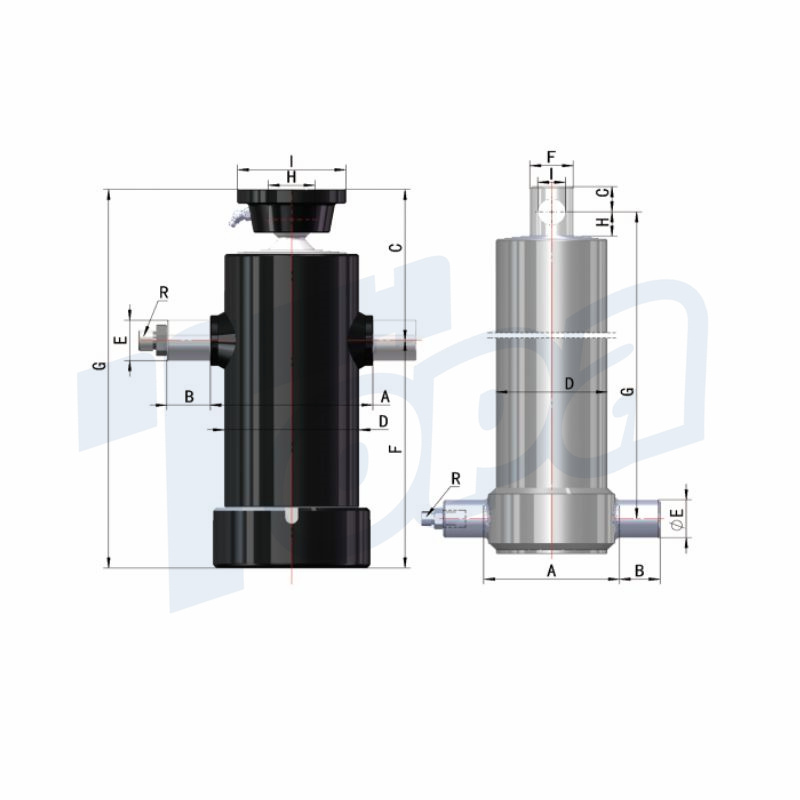

| Model | Stroke | Stages | CAP (T) | DIMENSIONS of cylinders in mm. | |||||||||

| A | B | C | D | E | F | G | H | I | R | ||||

| UTCB 75-3-630 | 630 | 3 | 3 | 115 | 40 | 140 | 95 | 35 | 234 | 374 | 43 | 100 | 1/2″ |

| UTCB 90-4-840 | 840 | 4 | 4 | 135 | 40 | 140 | 112 | 35 | 235 | 375 | 43 | 100 | 1/2″ |

| UTCB 105-4-830 | 830 | 4 | 9 | 150 | 40 | 157 | 124 | 40 | 228 | 385 | 55 | 115 | 1/2″ |

| UTCB 105-4-1310 | 1310 | 4 | 9 | 150 | 40 | 157 | 124 | 40 | 351 | 508 | 55 | 115 | 1/2″ |

| UTCB 105-4-1510 | 1510 | 4 | 9 | 150 | 40 | 157 | 124 | 40 | 401 | 558 | 55 | 115 | 1/2″ |

| UTCB 105-4-1710 | 1710 | 4 | 9 | 150 | 40 | 157 | 124 | 40 | 451 | 608 | 55 | 115 | 1/2″ |

| UTCB 105-4-1990 | 1990 | 4 | 9 | 150 | 40 | 157 | 124 | 40 | 521 | 678 | 55 | 115 | 1/2″ |

| UTCB 105-5-1040 | 1040 | 5 | 8 | 150 | 40 | 150 | 124 | 40 | 228 | 378 | 43 | 100 | 1/2″ |

| UTCB 105-5-1250 | 1250 | 5 | 8 | 150 | 40 | 150 | 124 | 40 | 267 | 417 | 43 | 100 | 1/2″ |

| UTCB 105-5-1500 | 1500 | 5 | 8 | 150 | 40 | 150 | 124 | 40 | 318 | 468 | 43 | 100 | 1/2″ |

| UTCB 125-5-1020 | 1020 | 5 | 11 | 175 | 45 | 165 | 152 | 45 | 222 | 387 | 55 | 115 | 1/2″ |

| UTCB 125-5-1230 | 1245 | 5 | 11 | 175 | 45 | 165 | 152 | 45 | 264 | 429 | 55 | 115 | 1/2″ |

| UTCB 125-5-1480 | 1480 | 5 | 11 | 175 | 45 | 165 | 152 | 45 | 315 | 480 | 55 | 115 | 1/2″ |

| UTCB 125-5-1630 | 1630 | 5 | 11 | 175 | 45 | 165 | 152 | 45 | 344 | 509 | 55 | 115 | 1/2″ |

| UTCB 125-5-1880 | 1880 | 5 | 11 | 175 | 45 | 165 | 152 | 45 | 395 | 560 | 55 | 115 | 1/2″ |

| UTCB 125-5-2130 | 2130 | 5 | 11 | 175 | 45 | 165 | 152 | 45 | 445 | 610 | 55 | 115 | 1/2″ |

| UTCB 125-5-2480 | 2480 | 5 | 11 | 175 | 45 | 165 | 152 | 45 | 515 | 680 | 55 | 115 | 1/2″ |

| UTCB 125-6-1480 | 1480 | 6 | 10 | 175 | 45 | 155 | 152 | 45 | 265 | 420 | 43 | 100 | 1/2″ |

| UTCB 125-6-1780 | 1780 | 6 | 10 | 175 | 45 | 155 | 152 | 45 | 315 | 470 | 43 | 100 | 1/2″ |

| UTCB 125-6-1960 | 1960 | 6 | 10 | 175 | 45 | 155 | 152 | 45 | 345 | 500 | 43 | 100 | 1/2″ |

| UTCB 125-6-2980 | 2980 | 6 | 10 | 175 | 45 | 155 | 152 | 45 | 515 | 670 | 43 | 100 | 1/2″ |

| UTCB 145-5-1585 | 1580 | 5 | 15 | 200 | 50 | 200 | 170 | 45 | 316 | 516 | 55 | 115 | 3/4″ |

| UTCB 145-5-2085 | 2080 | 5 | 15 | 200 | 50 | 200 | 170 | 45 | 416 | 616 | 55 | 115 | 3/4″ |

| UTCB 145-6-1920 | 1920 | 6 | 13 | 200 | 50 | 210 | 170 | 45 | 307 | 517 | 55 | 115 | 3/4″ |

| UTCB 145-6-2940 | 2940 | 6 | 13 | 200 | 50 | 210 | 170 | 45 | 477 | 687 | 55 | 115 | 3/4″ |

| UTCB 165-5-1500 | 1500 | 5 | 20 | 230 | 50 | 240 | 190 | 45 | 279 | 519 | 55 | 115 | 3/4″ |

| UTCB 165-5-1750 | 1750 | 5 | 20 | 230 | 50 | 240 | 190 | 45 | 329 | 569 | 55 | 115 | 3/4″ |

| UTCB 165-5-2000 | 2000 | 5 | 20 | 230 | 50 | 240 | 190 | 45 | 379 | 619 | 55 | 115 | 3/4″ |

| UTCB 165-5-2350 | 2350 | 5 | 20 | 230 | 50 | 240 | 190 | 45 | 449 | 689 | 55 | 115 | 3/4″ |

| UTCB 165-6-2130 | 2130 | 6 | 18 | 230 | 50 | 240 | 190 | 45 | 330 | 570 | 55 | 115 | 3/4″ |

| UTCB 165-6-2850 | 2850 | 6 | 18 | 230 | 50 | 240 | 190 | 45 | 450 | 690 | 55 | 115 | 3/4″ |

| UTCE 105-4-1310 | 1310 | 4 | 9.8 | 150 | 45 | 30 | 124 | 45 | 57 | 450 | 32 | 31 | 1/1″ |

| UTCE 105-4-1510 | 1510 | 4 | 9.8 | 150 | 45 | 30 | 124 | 45 | 57 | 500 | 32 | 31 | 1/0″ |

| UTCE 105-4-1710 | 1710 | 4 | 9.8 | 150 | 45 | 30 | 124 | 45 | 57 | 550 | 32 | 31 | 1/1″ |

| UTCE 105-4-1990 | 1990 | 4 | 9.8 | 150 | 45 | 30 | 124 | 45 | 57 | 620 | 32 | 31 | 1/2″ |

Customization options are readily available for hydraulic tipping cylinders. This allows for the tailoring of stroke lengths, mounting options, and pressure ratings to meet the precise requirements of different equipment and industries.

UTC - Hydraulic Tipping Cylinders

Tipping cylinders present a robust and cylindrical design. They are typically crafted from durable materials such as steel, featuring a piston and rod assembly. The outward appearance showcases a sturdy and dependable hydraulic component.

Tipping hydraulic cylinders are prominently used in various industrial applications, particularly in the handling and tilting of heavy loads. They are essential in sectors such as construction, agriculture, waste management, and transportation.

These cylinders are meticulously manufactured from high-strength materials, ensuring longevity and resilience in challenging environments. The choice of materials is a critical factor in their ability to endure the rigors of heavy-duty operations.

Advantages of Hydraulic Cylinders From Topa

Comprehensive Solutions: As a one-stop solution provider, Topa offers a wide range of hydraulic products and components. This convenience streamlines the procurement process for clients, saving time and effort.

Customization Expertise: Topa understands that each application is unique. They excel in tailoring hydraulic tipping cylinders to precise specifications, ensuring they perfectly align with their clients’ needs.

Global Reach: With a presence on international platforms like Alibaba and participation in exhibitions and trade shows, Topa Hydraulic ensures that its products reach clients worldwide, including the United States, Canada, Australia, and many more.

Cost-Performance Ratio: Clients appreciate the balance between cost and performance that Topa offers. Their products, manufactured in China, provide a favorable ratio, allowing clients to remain competitive without compromising on quality.