What are the Parts of a Hydraulic Cylinder ?

When it comes to the mechanics of heavy machinery, few components are as crucial as the hydraulic cylinder. Understanding each part of this essential device is not just about technical knowledge; it’s about grasping the heart of modern machinery. In this comprehensive guide, we’ll delve into the anatomy of a hydraulic cylinder, ensuring you have a clear picture of its inner workings.

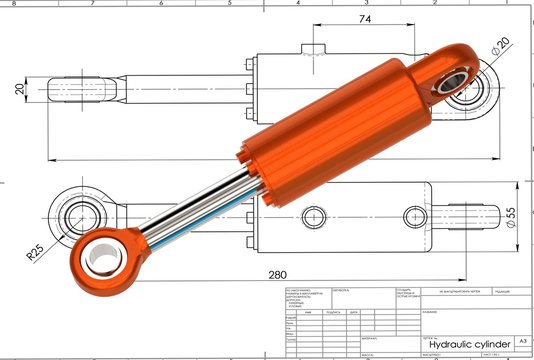

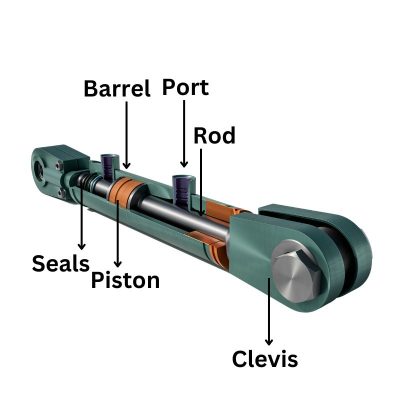

Basic Parts of a Hydraulic Cylinder

At its core, a hydraulic cylinder is a simple yet powerful device, comprising several key components: the barrel, piston, piston rod, head and base, seals, glands, clevis, and ports. Each part plays a vital role in the cylinder’s function. The barrel houses the piston and fluid, the Piston moves under fluid pressure, the piston rod transfers this motion and force, while the head and base enclose the system. seals and glands are crucial in preventing fluid leaks, ensuring efficient operation.

Basics of Hydraulic Cylinder

Explore each of the hydraulic cylinder parts in detail with us and learn about their role and contribution to the power and efficiency of the hydraulic cylinder. Whether you are an experienced engineer or a curious new learner, this guide will deepen your understanding of these precision machines.

At the heart of a hydraulic cylinder is a mechanical actuator that delivers unidirectional force through a unidirectional stroke. This seemingly simple concept is the driving force behind many applications in engineering. Whether it’s heavy lifting in construction or precision control in manufacturing, the core concept of the hydraulic cylinder is important. By harnessing the power of pressurized fluids, hydraulic cylinders convert energy into motion, making them an indispensable tool in a wide range of industries.

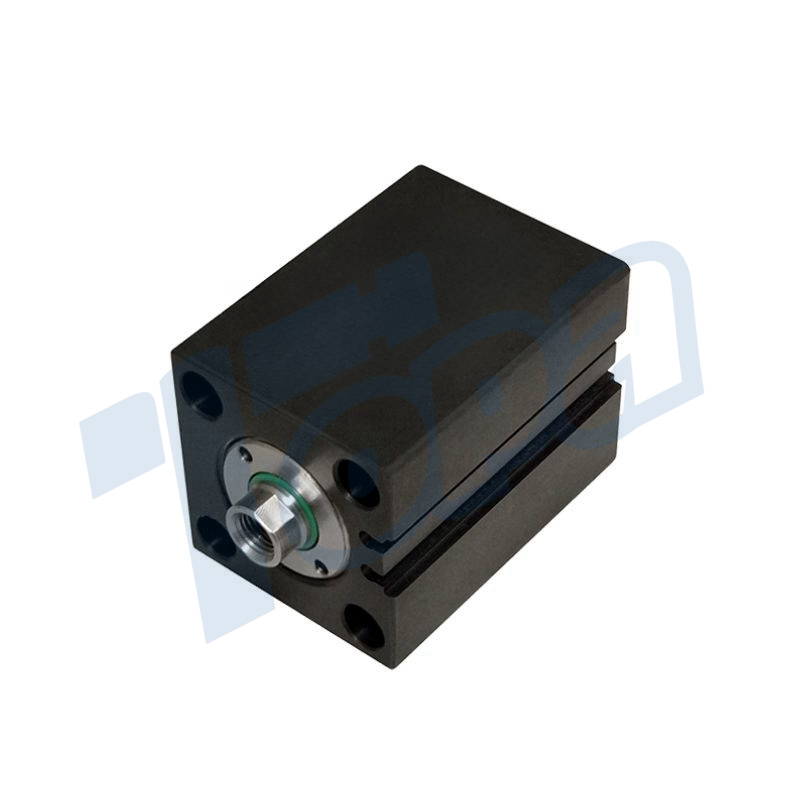

Barrel

The journey into the inner workings of a hydraulic cylinder begins with the unassuming but sturdy component known as the cylinder barrel. This cylindrical body is the core of the hydraulic cylinder and the primary housing for the fluid. Imagine it as a sturdy shell encasing the power and potential within.

The main function of the hydraulic cylinder barrel is to withstand the immense internal pressure generated during hydraulic operation. When hydraulic fluid is pumped into a hydraulic cylinder, it exerts a force on the inner wall of the cylinder barrel, which creates an outward force. However, hydraulic cylinder barrels are extremely strong and are not subject to any structural failure. This strength depends on the material, and in heavy-duty applications where the pressure generated by machinery can reach astronomical levels, a quality hydraulic cylinder barrel is vital.

The materials used to make cylindrical barrels are carefully selected for their toughness and durability. These cylinders are usually made from high quality steel that can withstand the rigors of the industrial environment. The choice of material is a key factor in ensuring that the cylinders operate reliably under varying conditions.

Piston

The hydraulic cylinder’s inner workings bring us to a crucial component that lies at the heart of its functionality—the Piston. At its core, the Piston serves as the dynamic force within the hydraulic cylinder. It’s the component that responds to the hydraulic pressure, translating it into mechanical movement. When hydraulic fluid is pressurized and introduced into the cylinder, it exerts force on the Piston, propelling it in a specific direction. This fundamental principle of pressure and movement is the essence of hydraulic power.

However, not all pistons are created equal. Hydraulic systems come in various shapes and sizes, each with unique requirements. Consequently, pistons are tailored to meet these specific needs. From single-acting to double-acting cylinders, and from compact machinery to heavy industrial applications, there’s a diverse range of pistons designed to excel in their respective roles.

Material selection for pistons is a critical consideration. The choice of materials depends on factors like operating pressure, temperature, and the environment in which the hydraulic cylinder operates. High-strength steel is a common choice due to its ability to withstand extreme pressures, while specialized coatings or treatments may be applied to enhance durability.

Piston Rods

As we continue to learn about the complex components of a hydraulic cylinder, we will look at a key part – the piston rod. It usually plays a vital role in ensuring that hydraulic power is converted into precise and reliable mechanical force however.

Essentially, the piston rod is the bridge between the piston and the external machinery that performs the actual work. The force generated by the hydraulic system is transmitted through the piston rod to accomplish tasks ranging from lifting heavy loads to controlling complex movements.

Piston rods are carefully designed and constructed to withstand the immense pressure exerted by hydraulic fluid. This component must withstand compression and tension cycles under extreme conditions, making it a very important accessory.

To meet these stringent requirements, piston rods are made from materials known for their strength and durability. Hardened steel is a commonly used material, known for its resistance to wear and deformation, ensuring the long-term integrity of hydraulic cylinders. Precision machining and surface treatments can further enhance the toughness of the rods, making them reliable tools for a variety of applications.

Heads and base

Cylinder heads and bases play a vital role in ensuring that hydraulic cylinders operate seamlessly under the tremendous forces they encounter. Their primary function is to enclose the hydraulic cylinder, creating a sealed chamber that holds the pressurized hydraulic fluid. Without cylinder heads and bases, hydraulic fluid would spill out, causing the cylinder to fail.

However, their role is not limited to sealing, but also includes maintaining the internal pressure necessary for the hydraulic cylinder to function. This function is critical because hydraulic systems rely on precise pressure levels to perform tasks accurately. The design of hydraulic cylinder heads and bases incorporates features that enable them to withstand the tremendous forces generated during operation.

Seals and Glands

The unassuming components of seals and glands play a key role in safeguarding hydraulic integrity by preventing leakage of hydraulic fluid. Their main task is both to create an impermeable seal within the hydraulic cylinder. Without them, hydraulic systems suffer from leakage, inefficiency and performance degradation.

Each type of seal is customized for a specific application. The materials used for these seals contain polyurethane, PTFE, and others. These materials are carefully selected to withstand the rigors of hydraulic operation. Different materials are adapted to factors such as pressure, acidic and alkaline environments, and temperature.

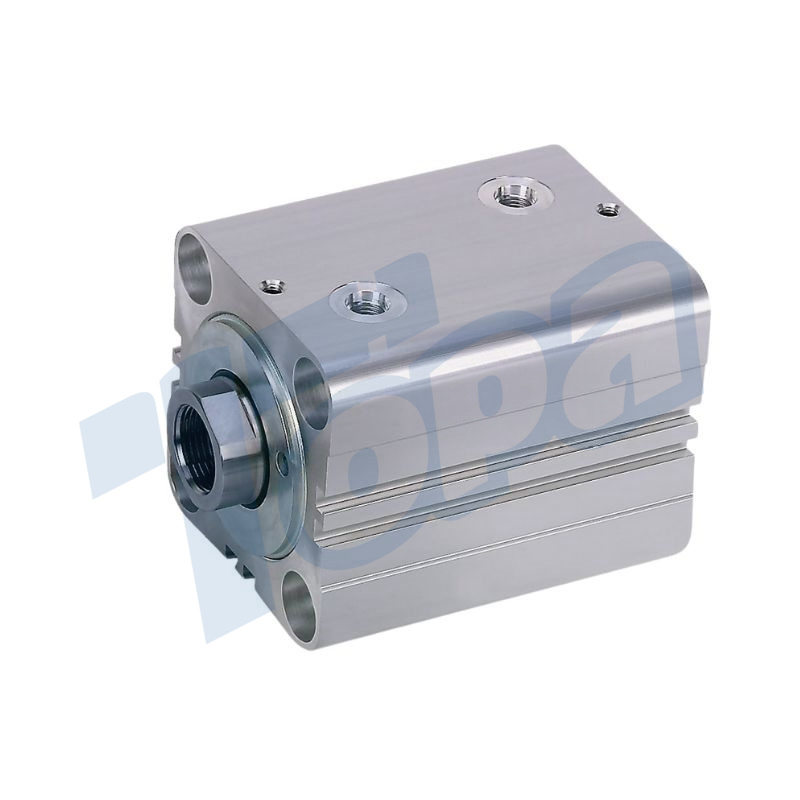

Ports

The ports are the channels through which hydraulic fluid moves in and out of the hydraulic cylinder. They facilitate the interaction between the hydraulic system and the hydraulic cylinders, resulting in precise control of the fluid flow. This control is at the heart of the hydraulic cylinder’s ability to generate force and perform precise motions.

The type of port and its configuration are critical to customizing a hydraulic cylinder for a specific application. Whether you are designing a single-acting hydraulic cylinder with one port for fluid entry and exit or a double-acting cylinder with multiple ports for bi-directional movement, the choice of port is dictated by the intended function.

The ports must be able to withstand the pressures and fluid characteristics encountered during hydraulic operation. Materials such as stainless steel or high-strength alloys are often chosen to ensure durability and corrosion resistance.

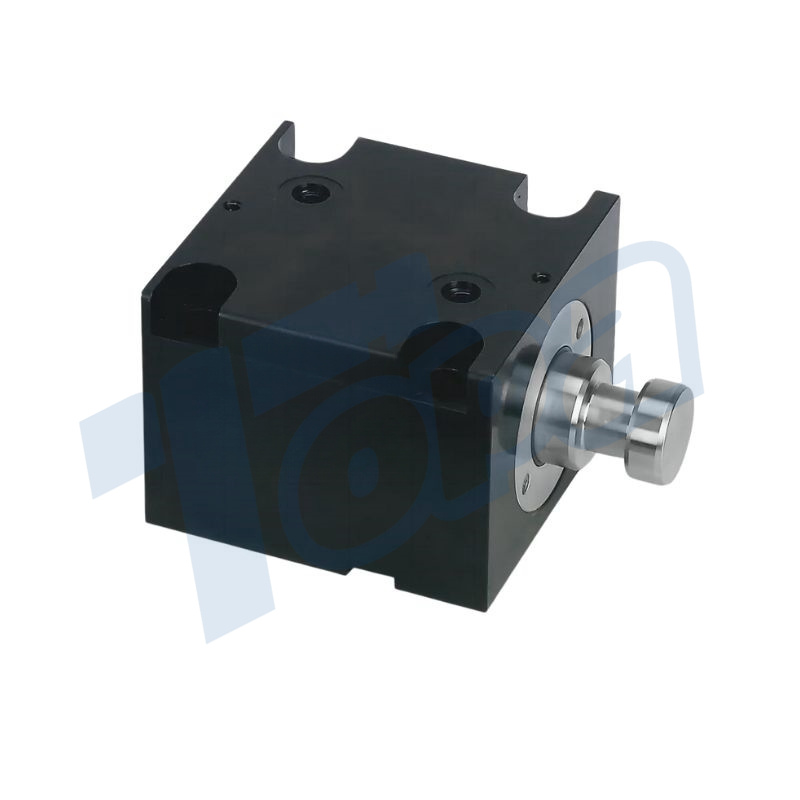

Clevis

A clevis is an integral part of a hydraulic cylinder used as a pivot mounting system. It is designed for pivot mounting and allows the hydraulic cylinder to move along its axis in a single range of motion. This feature is particularly important in applications where the hydraulic cylinder needs to move through a circular pivot during the extension and retraction phases.

The clevis is attached to the hydraulic cylinder cover and plays a vital role in maintaining pressure within the hydraulic cylinder barrel. It is mainly used in hydraulic systems for mobile industrial and construction equipment, such as the movable arms of excavators. And it is particularly suitable for hydraulic cylinders with small to medium bores and short strokes.

The clevis is mounted to the end of the hydraulic cylinder using a mounting bracket, secured with a steel pin and held in place with a cotter pin or snap ring. Mounting in this manner provides a solid connection for the hydraulic cylinder. Clevis mounting has the advantage of centerline mounting, which improves the efficiency of the hydraulic cylinder. However, it should be noted that due to their single range of motion, wedges are prone to side loading problems. To alleviate this problem, sometimes a spherical bearing can be used with the clevis to allow for some degree of misalignment, thereby extending the life of the hydraulic cylinder and preventing premature failure.

Other hydraulic cylinder mounting options:

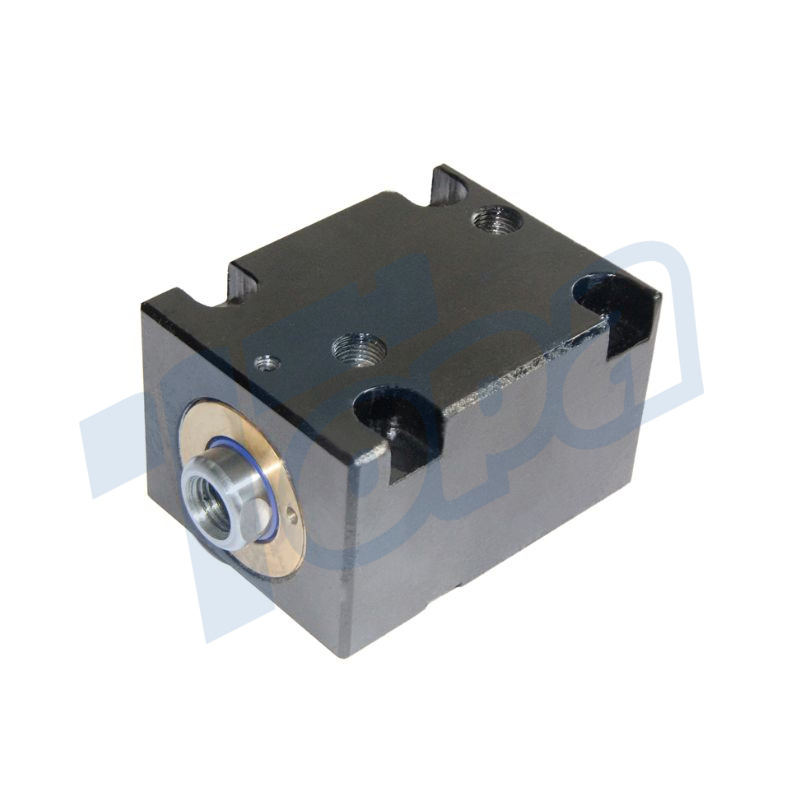

Flange Mount:

Characteristics: The flange mount involves fixing the hydraulic cylinder through a flat plate at its head. This connection has no joints or bearings and is fixed at the cylinder’s centerline.

Advantages: Offers high strength and stability, suitable for applications that require heavy loads and high strength.

Trunnion Mount:

Characteristics: The trunnion mount resembles a cylindrical extension that forms a mounting point. This design was originally used for mounting old cannons, allowing them to pivot up and down.

Advantages: Allows the cylinder to swing within a certain range, suitable for applications that need some degree of swinging freedom.

Lug Mount:

Characteristics: The lug mount is a fixed-style mounting option, achieved by machining or welding rectangular tabs onto the cylinder’s head and cap.

Advantages: Provides good strength and stability but, like other fixed-type mounts, has a lower tolerance for misalignment.

Spherical Bearing Connections:

Characteristics: In some connections, such as the clevis mount, spherical bearings may be used to allow a degree of misalignment.

Advantages: Can reduce the effects of misalignment, extending the life of the cylinder.

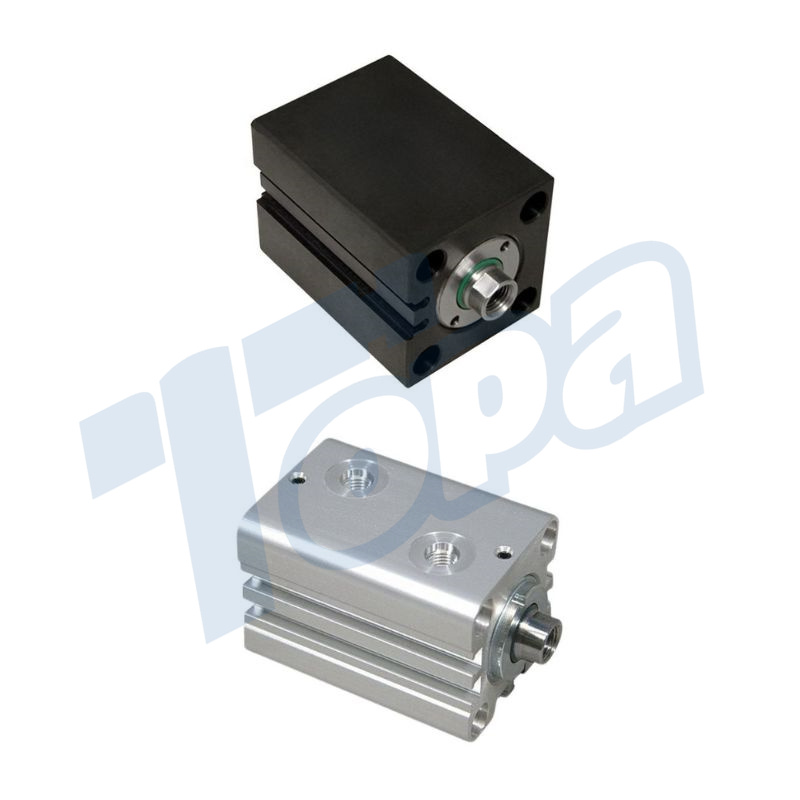

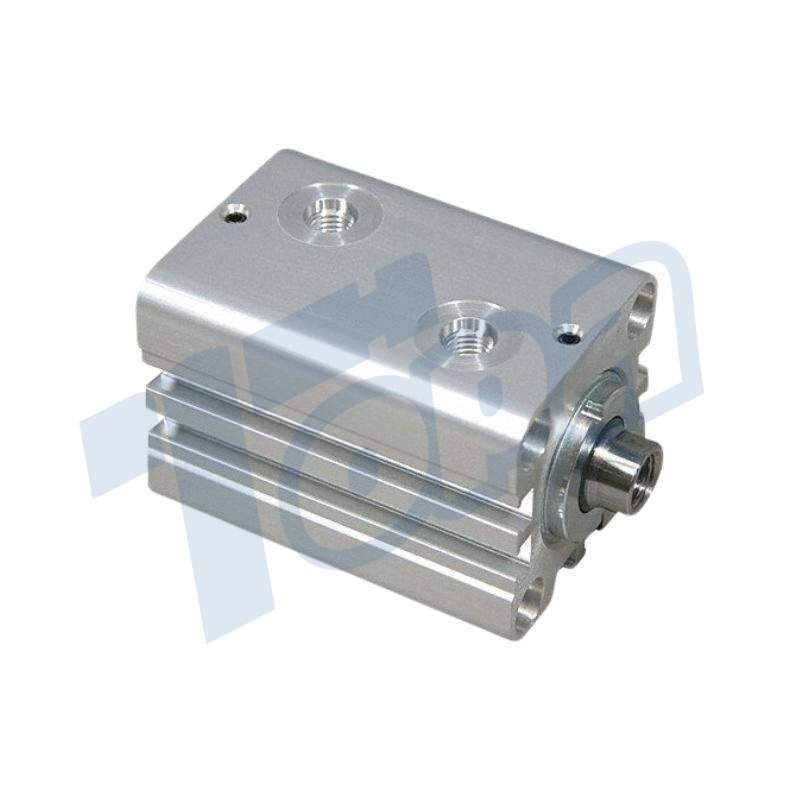

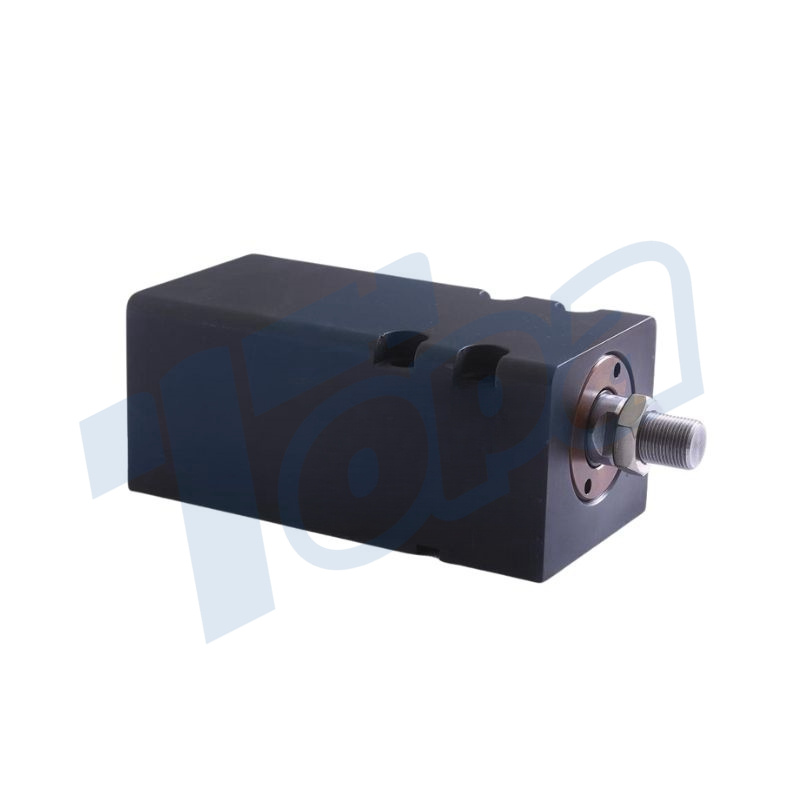

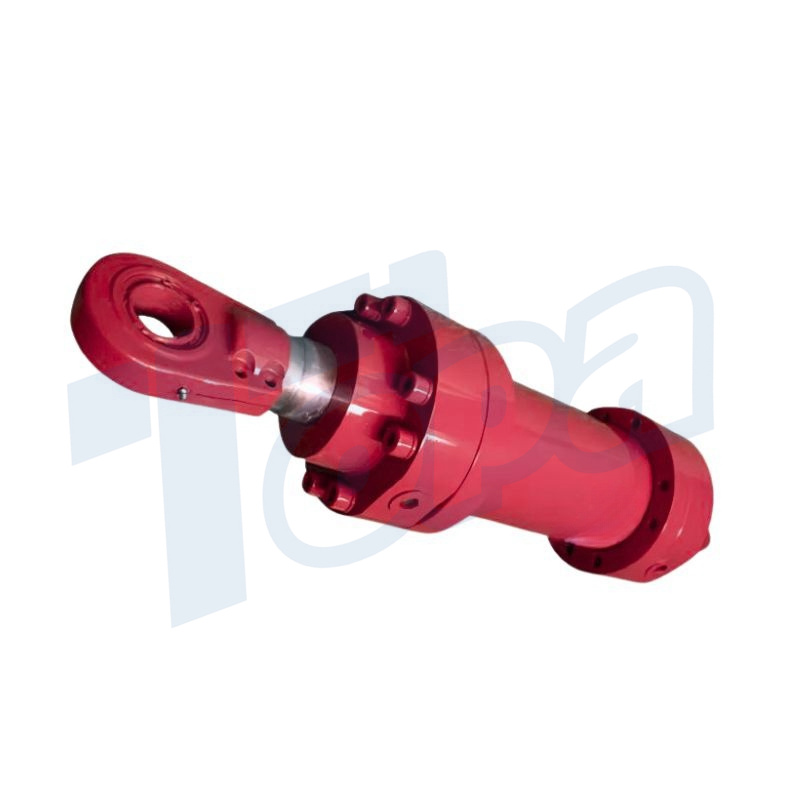

Different Hydraulic Cylinder Types

Hydraulic cylinders span a spectrum of types, each designed for distinct purposes. These include tie-rod cylinders, welded body cylinders, telescopic cylinders, and compact cylinders, among others. The selection of the right type hinges on factors like space constraints, load capacity, and environmental conditions.

Single-Acting vs Double-Acting

One of the fundamental differences in hydraulic cylinders lies in their actuation. Single-acting cylinders use hydraulic fluid pressure to generate force in one direction, typically requiring an external force for the return stroke. In contrast, double-acting cylinders can apply force in both directions, using hydraulic pressure for both extension and retraction. The choice between these two types depends on the specific needs and constraints of the application.

When selecting a hydraulic cylinder type, it’s crucial to align your choice with the demands of the application. For example, if you require precise control over both extension and retraction, double-acting cylinders are the preferred choice. On the other hand, single-acting cylinders may be suitable for applications where force is primarily needed in one direction, such as lifting or pushing.

Some hydraulic cylinder types come with specialized features to cater to unique requirements. For instance, telescopic cylinders are known for their space-saving design, making them ideal for applications with limited room for cylinder extension. Understanding these specialized features can help you make an informed decision when choosing the right cylinder type for your specific needs.

How to Assembly Hydraulic Cylinder Parts Together?

Assembling the components of a hydraulic cylinder is a precise and methodical process that requires attention to detail and an understanding of the mechanics involved. Here’s a step-by-step guide on how to assemble the parts of a hydraulic cylinder:

Prepare the Components

Before starting the assembly, ensure that all the parts of the hydraulic cylinder – the barrel, piston, piston rod, cylinder head, cylinder base, seals, glands, clevis, and ports – are available and in good condition. It’s crucial to inspect each component for any signs of damage or wear.

Install the Seals

Begin by installing the seals in the cylinder head and base. The seals are critical for preventing fluid leaks and maintaining the efficiency of the cylinder. Make sure that the seals are properly seated and lubricated to facilitate smooth movement.

Assemble the Piston onto the Rod

Attach the piston to the piston rod. This is usually done by threading the piston onto the rod or securing it with bolts or nuts. Ensure that the connection is tight and secure.

Insert the Piston and Rod into the Barrel

Carefully slide the piston and rod assembly into the barrel. This step must be done with care to avoid damaging the seals or the interior surface of the barrel.

Attach the Cylinder Head and Base

Once the piston and rod are inside the barrel, attach the cylinder head and base to either end of the barrel. These components are typically bolted or threaded onto the barrel. Ensure that they are aligned correctly and secured tightly.

Connect the Clevis (if applicable)

If the cylinder uses a clevis for mounting, attach it to the end of the piston rod. The clevis must be securely fastened to ensure a stable connection.

Attach the Ports

Finally, install the ports on the cylinder. The ports are the channels through which the hydraulic fluid will enter and exit the cylinder. Make sure they are properly aligned and secured.

Final Inspection

Once the cylinder is fully assembled, conduct a thorough inspection to ensure that all parts are correctly installed and there are no leaks. It’s also advisable to perform a pressure test to verify the integrity of the assembly.

Lubrication and Protection

Apply lubrication where necessary, especially on moving parts like the piston rod. Additionally, consider applying a protective coating to prevent corrosion, especially if the cylinder will be used in harsh environments.

If you still have more concerns, you can refer to this video to learn how to install hydraulic cylinders:

Conclusion

Understanding each component of a hydraulic cylinder is more than just technical knowledge; it’s about appreciating the ingenuity behind the machine. From the sturdy cylinder barrels to the intricate seals, these components work in harmony to convert hydraulic pressure into mechanical movement for heavy lifting, precise control and powerful maneuvers that drive industries around the globe. If you are ready to explore further or learn about the latest developments in hydraulics, please continue to visit our website.