How to Identify Hydraulic Fittings ?

Hydraulic fittings are a crucial component in many industries, including manufacturing, construction, aviation, and many other areas where hydraulic systems are used. And since there are numerous classifications of hydraulic fittings and differences in application environments, you need to have basic fitting information to be able to accurately distinguish fittings. Here are some key steps that will help you identify hydraulic fittings more accurately:

Identify the Type of Fittings

You can simply determine the type of hydraulic fitting by the appearance of the fitting. Common hydraulic fittings can be broadly classified into the following categories:

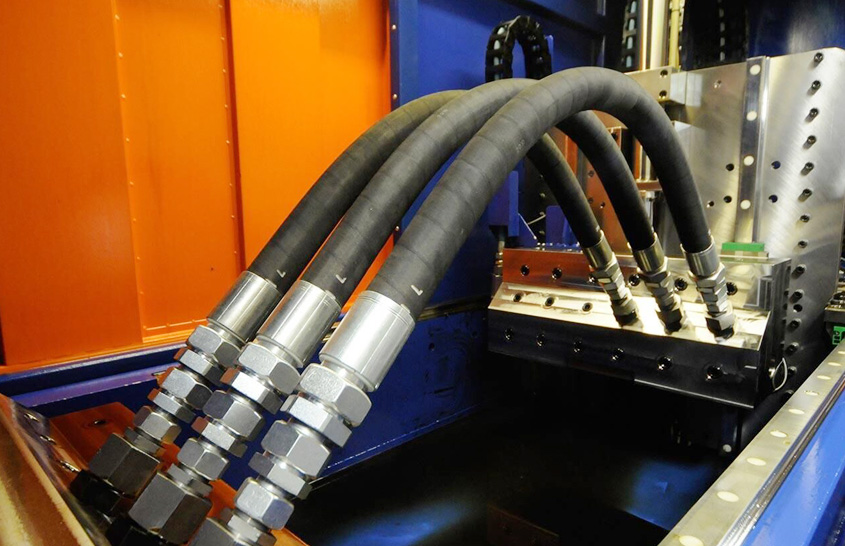

Hose Fittings

Hose fittings are used to connect with hydraulic hoses. They have a hose port on one end, which can be inserted into a hose and used in a hydraulic system. The other end is a threaded end, either male or female, and is used with other fittings or components. Hose fittings are available with bends from 15 degrees to 180 degrees included and can be used in a variety of applications.

Adapters

Hydraulic adapters are the most common type of fitting. Each port of those fittings is threaded end and there exists a variety of different threads. Adapters include many types of hydraulic fittings: like tees, crosses, plugs, caps, bulkheads, grease nipples, etc. The different adapters have their own specific appearance and are very easy to distinguish.

Compression Fittings

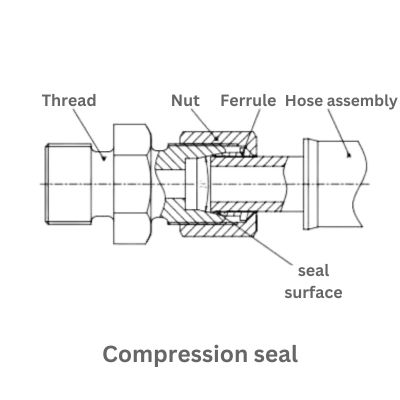

There are three parts to a compression fitting: the nut, the ferrule, and the fitting. Commonly, there is a one-piece ferrule fitting and a two-piece ferrule fitting, which means that one or two ferrules are present in the fitting. These fittings can be used in tight places and do not require additional tools for installation.

Permanent or Reusable Fittings

Permanent hydraulic fittings, also known as one-piece fittings, are crimped fittings that are one piece. They are easy to install and operate and are the most popular type of fitting.

Reusable fittings have removable sleeves. They can be installed with a sleeve to hold the hose in place without causing displacement. Reusable hydraulic fittings are commonly used in applications that require field disassembly, saving most of the operating time.

Quick Connects

Quick disconnect fittings are divided into two parts, the plug and the coupler, which are mounted together with a single push. Quick disconnects increase user productivity by minimizing the time spent establishing and disconnecting fluid connections.

Identify Thread Types

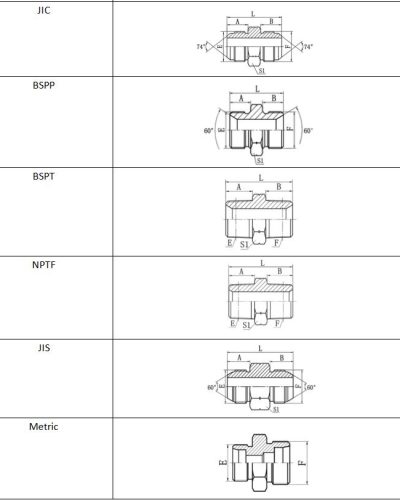

Threads are generally present in hydraulic fittings, and threads are all available at different standards. Common thread standards include American Standard Thread, British Standard, and International Metric Thread System.

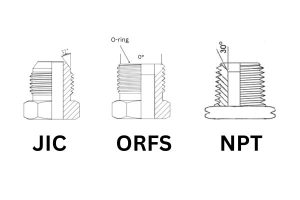

American Standard Thread

American Standard threads have two notch marks on the outside of the fitting and a “U” on the thread cap. There are many types of threads involved in the American Standard thread, including JIC, NPT, and ORFS threads.

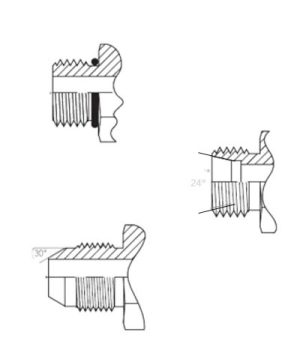

JIC fittings are straight threads with a 37-degree flare cone on both the internal and external thread cones. NPT fittings are tapered threads with a 30-degree chamfered internal flare, NPTF fittings are upgraded versions of NPT for better sealing. And ORFS fittings are straight threads with a groove on the top of the fitting to allow for the installation of an O-ring.

British Standard Threads

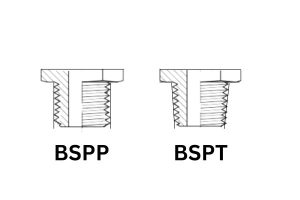

BSP fittings are marked with a notch on the surface and a “G” on the thread cap. BSPP threads are straight threads with a 60-degree chamfer on the male thread and a 60-degree taper on the female thread (swivel fitting). They can be sealed with a sealant or gasket.

BSPT fittings have a tapered thread, which can be easily confused with NPT. However, BSPT fittings do not have any chamfers, while NPT fittings have a 60-degree chamfer.

Metric Standard Threads

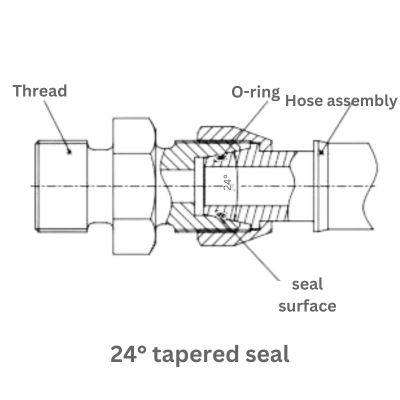

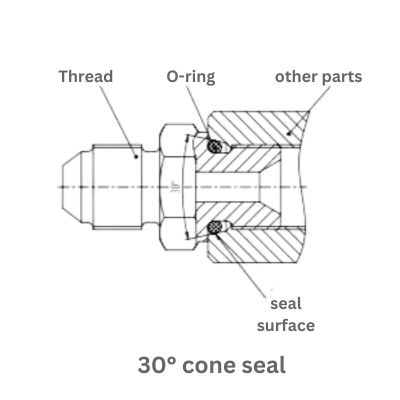

Metric threads are abbreviated as “M” and they are one of the most common threads used in hydraulic fittings. Globally, there are three standard metric fittings: DIN metric, JIS metric, and Komastu metric fittings. DIN metric fittings often have 24°, 45°, and 30° tapers. Some common fittings also require the help of O-rings or other seals.

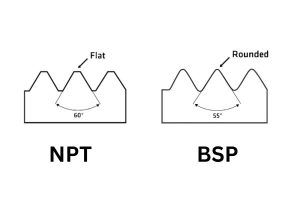

Metric, BSP, and American fittings also differ in thread shape (the angle between adjacent threads), with American and metric fittings having a 60° thread shape and metric threads having a 55° thread shape.

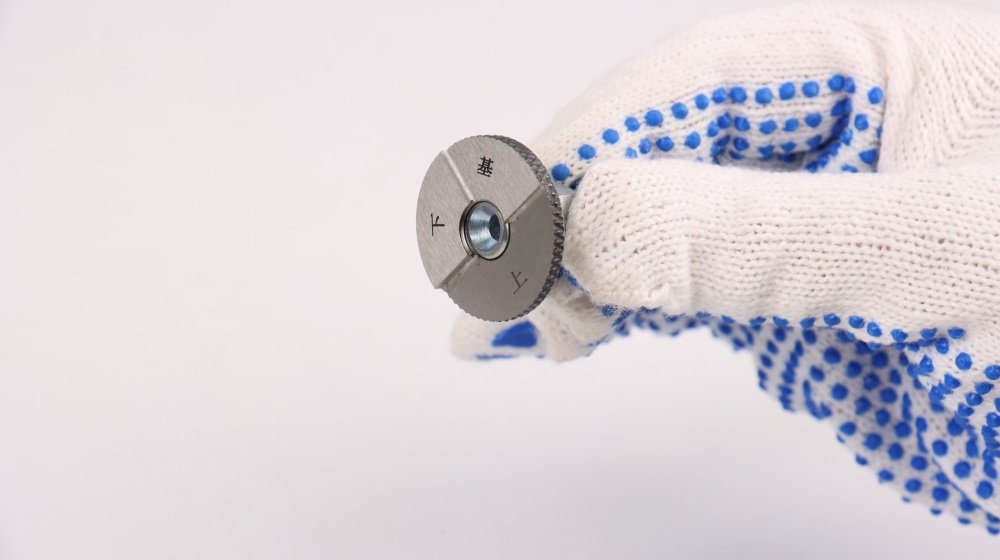

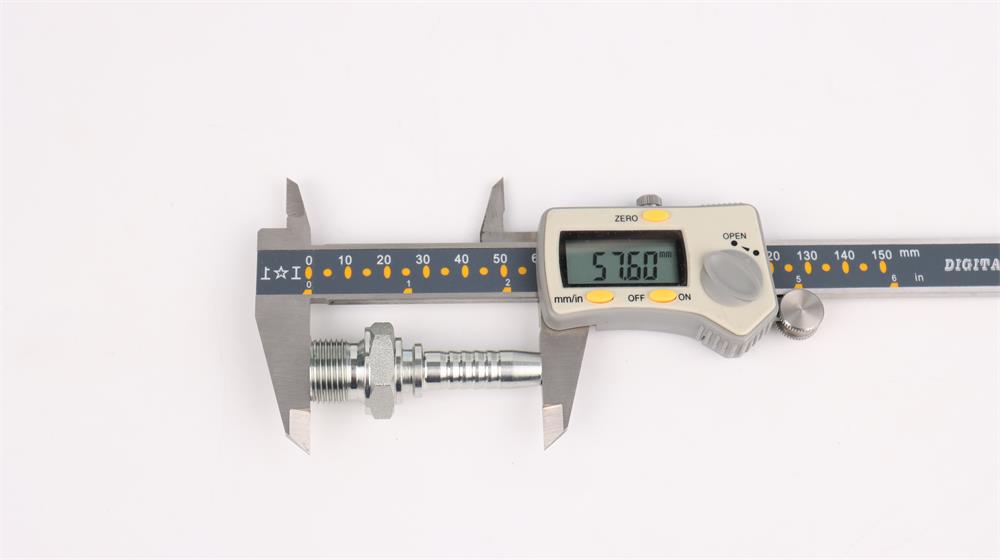

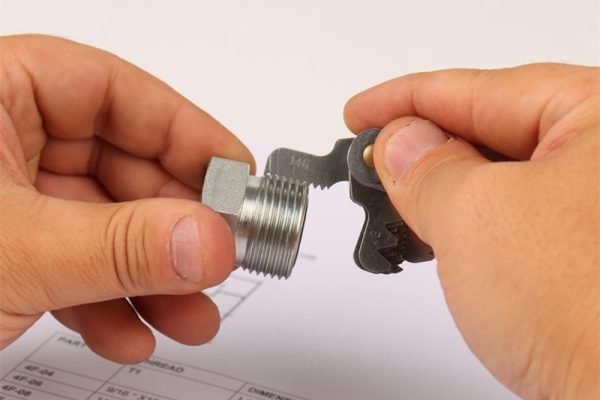

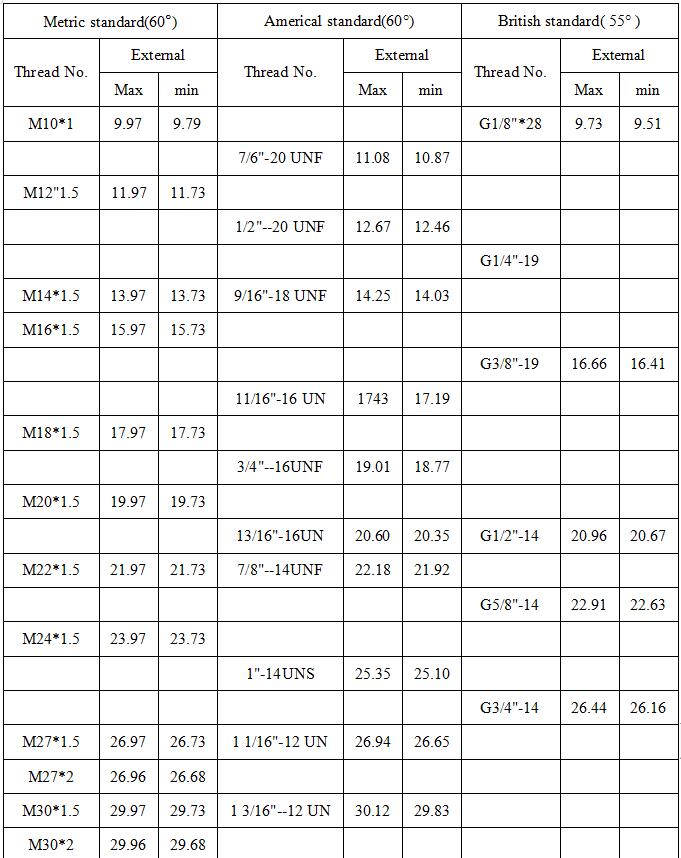

Measuring Dimensions

Once you have identified the type of fitting, then you need to determine the size of the fitting. Vernier calipers and pitch gauges are used to measure the size of the fitting. Vernier calipers can be used to measure the length, I.D., and O.D. of the fittings. The pitch gauge is used to determine the pitch of the adapter. These data can be measured to correspond to the supplier’s data, and then the corresponding joint can be selected.

Note: Do not use these steps to determine the internal threads. If you want to determine the female threaded fitting, you can first distinguish the male threaded fitting and then go directly to the corresponding female thread.

The measured data may be in error with the standard data. However, the measured diameter should not be larger than the standard data.

Conclusion

It is not difficult to distinguish hydraulic fittings, but it is necessary to be careful and distinguish all the details of the fittings. If you really can’t tell the type of hydraulic fittings, please take a detailed picture or video and contact us, Topa can give you a comprehensive answer!

Other Articles

What are hydraulic fittings?

Different types of hydraulic fittings

How to seal hydraulic fittings?

How to measure hydraulic fittings?

BSP vs NPT thread: what are the differences?

How do you stop a hydraulic fitting from leaking?

How tight should hydraulic fittings be?

How to attach hydraulic hose fittings?