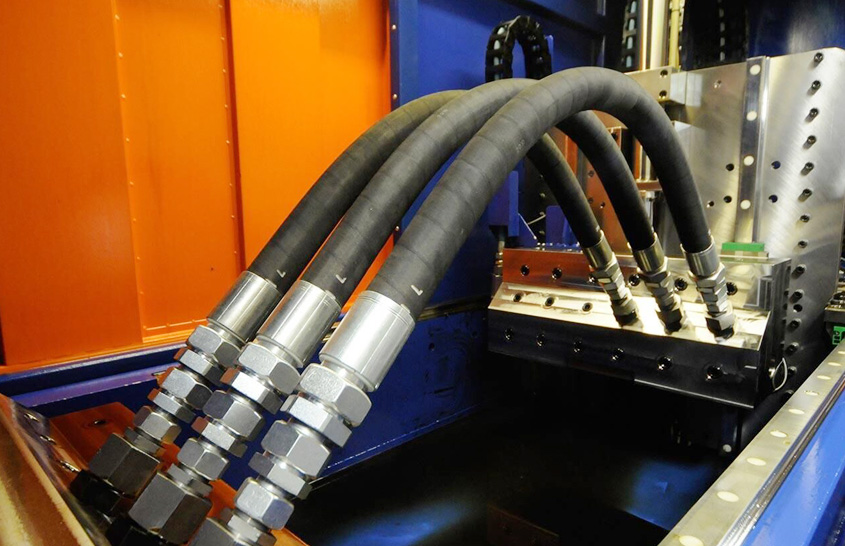

Hydraulic hoses are a critical component of hydraulic systems, and their failure can cause significant damage to machinery and equipment. Here are some common causes of hydraulic hose failure and how to prevent them:

- Abrasion and Wear: Hydraulic hoses can experience abrasion and wear due to continuous exposure to moving parts, sharp edges, and other harsh environmental conditions. To prevent abrasion, ensure that hoses are properly routed and protected, and use abrasion-resistant materials.

- Overheating: High temperatures can cause the rubber in hydraulic hoses to degrade, leading to cracks and leaks. To prevent overheating, ensure that the hydraulic system is properly cooled and that hoses are not exposed to excessive heat.

- Pressure Spikes: Hydraulic hoses can fail due to pressure spikes caused by rapid changes in pressure within the system. To prevent pressure spikes, use pressure relief valves and ensure that the system is properly designed and maintained.

- Improper Assembly: Hydraulic hoses can fail due to improper assembly, such as incorrect crimping or incorrect installation of fittings. To prevent improper assembly, follow the manufacturer’s instructions and use the proper tools and equipment.

- Chemical Degradation: Hydraulic hoses can degrade due to exposure to chemicals, such as hydraulic fluid, solvents, and cleaners. To prevent chemical degradation, use hoses made from materials that are resistant to the specific chemicals in the hydraulic system.

- Fatigue: Hydraulic hoses can fail due to repeated bending and flexing, leading to cracks and leaks. To prevent fatigue, ensure that hoses are properly supported and use hoses made from materials that are resistant to fatigue.

By understanding the common causes of hydraulic hose failure and taking steps to prevent them, you can ensure the long-term reliability and performance of your hydraulic system.