FAQ

Hose barb fittings are commonly made from materials like brass, stainless steel, or aluminum, selected based on application requirements for durability and compatibility.

Yes, hose barb fittings are designed to accommodate various types of hoses including PVC, rubber, silicone, and polyethylene, offering versatility in fluid handling applications.

It’s crucial to match the fitting’s material and size specifications with the hose type and system pressure ratings. Consulting with our technical support team can ensure compatibility.

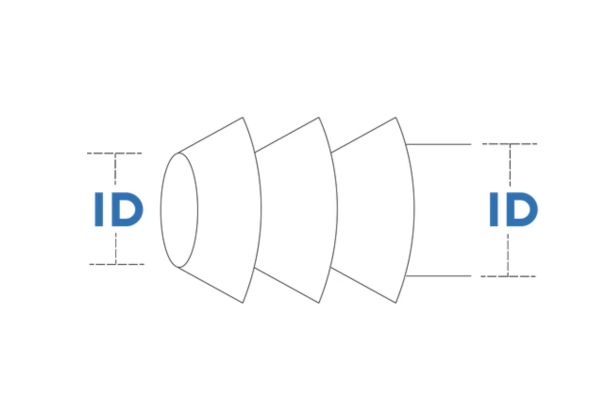

Hose barb fittings come in a range of sizes typically measured in inches or millimeters, catering to different hose diameters and fluid flow requirements.

Yes, hose barb fittings require hose clamps or crimped ferrules to securely attach hoses and prevent leaks. Proper installation ensures a tight seal.

Yes, depending on the material and design, hose barb fittings can be suitable for both low and high-pressure applications. It’s essential to select fittings rated for the specific pressure range needed.

Yes, hose barb fittings are versatile and can be used for both liquid and gas applications. The choice of material and proper installation ensure compatibility and safety.

Installation typically involves pushing the hose onto the barbed end of the fitting and securing it with a hose clamp or crimping tool. Following manufacturer guidelines ensures a proper fit.

Regular inspection for wear or corrosion is recommended to maintain optimal performance. Replace worn fittings promptly to prevent leaks and ensure system integrity.

Topa provides comprehensive technical support, including guidance on selection, installation, and troubleshooting. Contact our team for expert assistance tailored to your needs.