Quickly Identify Hydraulic Fittings: What Should You Do?

Table of Contents

Introduction

Misidentification can result in the installation of incompatible or inadequate fittings, leading to leaks, system inefficiencies, or worse, catastrophic failures. Thus, technicians and engineers must be adept at quickly and accurately identifying various types of fittings to ensure they match the specifications and demands of their systems. This article aims to arm professionals with practical tips and essential tools for the swift identification of hydraulic fittings in various field settings.

Types of Hydraulic Fittings

Hydraulic fittings play a pivotal role in connecting components within hydraulic systems, ensuring fluid flows efficiently and without leaks under high pressure. Understanding the types, their applications, and identification tips is crucial for professionals who handle hydraulic machinery.

Hydraulic Hose Fittings

Description and Visual Identification Tips:

Hydraulic hose fittings are designed to connect hoses to components like hydraulic cylinders, valves, and pumps. They typically feature a barbed end to grip the inside of a hose and may have a threaded or flanged end to connect to the system. These fittings are often made from strong metals like steel or brass to withstand high pressures. Visually, hose fittings are recognized by their robust construction and multiple ridges or barbs.

Common Applications and Examples:

These fittings are used extensively in mobile hydraulics, construction equipment, and industrial machinery. For example, an excavator uses hydraulic hose fittings to connect its hydraulic hoses to the hydraulic pump and cylinders, facilitating the smooth operation of its moving parts.

Hydraulic Adapters

Functionality and Distinguishing Features:

Hydraulic adapters are used to connect different types of fittings and are essential for transitioning between various thread types or sizes. They often come in shapes such as straight, elbow, or tee, with male and female ends of differing types. Adapters can be identified by their geometric shapes and the presence of different threading on each end.

Material Types and Their Implications:

Materials commonly used for adapters include stainless steel, carbon steel, and brass. The choice of material affects the fitting’s corrosion resistance and suitability for different fluids and environmental conditions. Stainless steel adapters are preferred in corrosive environments, while brass is typically used for lower pressure settings.

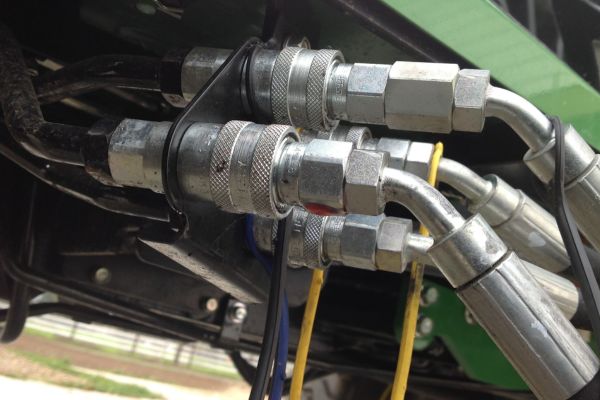

Quick Couplings

How They Work and Common Uses:

Quick couplings, or quick-connect fittings, allow for fast connection and disconnection of hydraulic lines without the need for tools. These fittings generally have a male part (the plug) and a female part (the socket) that snaps together with a simple push-pull action. They are equipped with seals to prevent leaks during disconnection and connection.

Quick Identification Guide for Rapid Deployment:

Quick couplings are identifiable by their push-pull locking mechanism and the presence of a release sleeve on the socket. They are widely used in applications requiring frequent disassembly or where flexibility is needed, such as in agricultural implements or industrial machinery maintenance.

Banjo Fittings

Characteristics and Unique Identification Markers:

Banjo fittings are named for their distinctive shape that resembles a banjo. These fittings have a hollow bolt passing through a perforated circular plate, allowing fluid to flow through the bolt. They are easily identified by this unique structure.

Usage Scenarios and Compatibility:

Banjo fittings are commonly found in automotive fuel, oil, and hydraulic brake systems where space is limited and bending of hoses is required. Their design allows for a compact connection without excessive bending of the hydraulic hose.

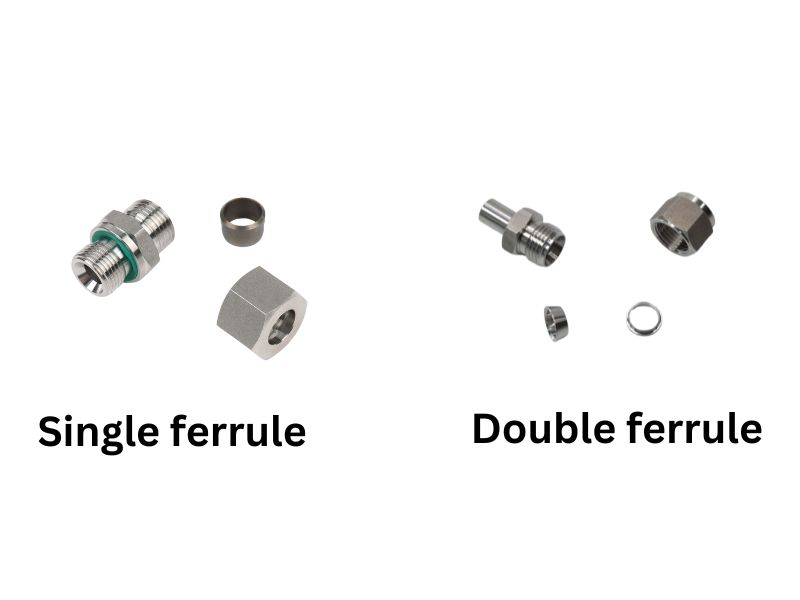

Ferrule Fittings

Detailed Description and How They Differ from Other Fittings:

Ferrule fittings consist of a circular clamp (ferrule) that tightens around the hose to secure it to the fitting body. These are typically used with softer hoses to provide a tight seal by compressing the hose between the ferrule and the fitting body.

Importance in Hydraulic Systems:

The ferrule creates a seal that can withstand high pressures, making these fittings essential for high-pressure applications like chemical processing or oil and gas delivery. They differ from other fittings in that they provide a permanent, leak-proof seal that is crucial for maintaining system integrity.

Identification Marks on Fittings

Accurate identification of hydraulic fittings in the field can significantly streamline maintenance and setup processes. Manufacturers often utilize specific marking systems on fittings to aid in this identification. Two common methods include hexagonal markings and cap identifications.

Hexagonal Markings

Explanation of Markings Found on Hexagonal Fittings:

Hexagonal fittings often feature small notches or markings on their hexagonal surfaces. These markings are not merely decorative; they provide essential information about the fitting’s standard and specifications. Typically, these are machined into the fitting during manufacturing and are designed to be easily visible to aid quick identification.

Decoding the Meaning of Single vs. Double Notches:

Single Notch: Generally indicates that the fitting adheres to British standards (BSPP, BSPT). These fittings are commonly used in applications requiring a reliable seal in the presence of high fluid pressure.

Double Notch: Indicates that the fitting conforms to American standards (NPT, JIC). This differentiation is crucial as mixing components from different threading standards can lead to leaks or thread damage.

Understanding these markings can prevent costly errors in system assembly, ensuring compatibility and functionality.

Cap Identification

How to Use Markings on Fitting Caps for Identification:

Manufacturers may also place identification marks on the caps of fittings. These caps protect the fitting during shipping and handling but can also serve as a quick reference point for technicians. Markings on caps can include the type of thread, size, and sometimes the material of the fitting. For example, a cap might be marked with “M16x1.5” indicating a metric thread with a diameter of 16 mm and a pitch of 1.5 mm.

Visual Examples for Clarity:

To aid in understanding, visual examples of cap markings include:

A cap marked with “SS” typically denotes stainless steel material, suggesting suitability for corrosive environments.

A cap with “3/8 NPT” indicates a 3/8 inch National Pipe Tapered thread, common in general industrial applications.

These cap identifications, combined with other markings, allow field technicians to quickly verify fitting characteristics without the need for additional tools or reference materials, streamlining maintenance and ensuring system integrity.

Thread Appearance

The thread type of a hydraulic fitting is crucial for ensuring compatibility and seal integrity within hydraulic systems. Different industries and regions might favor specific thread types based on standards and requirements. Recognizing these thread types visually can save time and prevent the common pitfalls of mismatching components.

Overview of Common Thread Types

Characteristics of Common Thread Types:

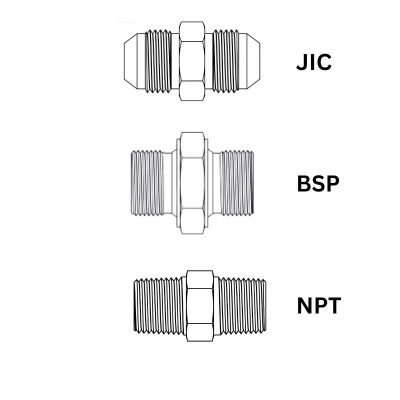

JIC (Joint Industry Council): JIC threads are characterized by their 37-degree flare seating surface and are often used in high-pressure applications. They are similar in appearance to AN (Aerospace Number) fittings used in military applications.

SAE (Society of Automotive Engineers): SAE threads are also flared (usually at 45 degrees) and are typically used in automotive and heavy equipment applications. They are robust and designed for medium to high-pressure conditions.

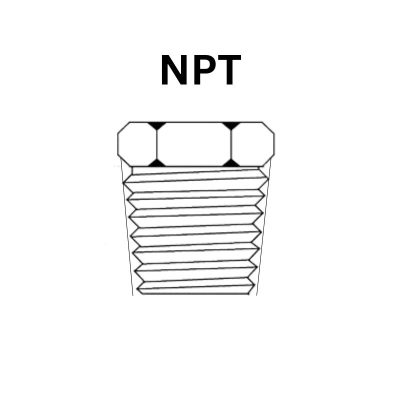

NPT (National Pipe Tapered): NPT threads are tapered and designed to provide a tight seal through the threading itself, making them ideal for plumbing applications. They require thread sealant or Teflon tape to ensure a leak-proof connection.

BSP (British Standard Pipe): BSP threads can be either parallel (BSPP) or tapered (BSPT). BSPP threads are commonly found in European equipment and require a bonded seal, while BSPT threads create a mechanical seal through thread engagement.

Metric: These threads are specified by the thread’s outer diameter and the pitch in millimeters, common in most non-North American equipment. Metric threads are straightforward and do not usually require flaring.

ORFS (O-Ring Face Seal): These have a flat sealing surface with an O-ring in a groove on the face of the fitting, providing an excellent seal. They are widely used in hydraulic systems where leakage is a critical concern.

Visual Comparison and Identification Tips:

Visually, JIC fittings can be distinguished by their shiny, metallic flare, while SAE fittings generally have a more pronounced thread and flared angle. NPT fittings taper towards the end, making them visually narrower at the tip than at the base. BSP threads are very uniform and symmetrical. Metric threads look very similar to BSP but are measured in metric units. ORFS fittings are recognizable by their flat face and visible O-ring.

Using Thread Charts and Gauges

How to Use Thread Charts Effectively:

Thread charts are essential tools for identifying thread types and sizes. These charts provide detailed illustrations and specifications of different threads. To use a thread chart effectively, measure the outer diameter of a male thread or the inner diameter of a female thread, then compare these measurements with the chart to determine the thread type and size.

Recommended Thread Gauges for Field Use:

Caliper-style Thread Gauge: Allows for quick and accurate measurement of the diameter and pitch of a thread.

Screw Pitch Gauges: Useful for determining the pitch of the thread by matching the teeth on the gauge with the thread.

Combination Gauges: These gauges combine features for measuring diameter, pitch, and thread type in one tool.

Carrying these gauges in the field allows technicians to quickly verify the thread type of a fitting, ensuring that replacements or repairs are done with the correct components, thus maintaining system integrity and function.

Determining Thread Angles

Thread angles are critical features in the identification and compatibility of hydraulic fittings, as they influence the type of seal formed and the fitting’s suitability for specific pressures and applications. Understanding how to measure and identify these angles can prevent equipment failures and maintain system integrity.

Thread Angle Identification

BSP (British Standard Pipe): BSP threads can be either parallel or tapered, but the thread angle is consistently set at 55 degrees. This angle helps in forming a tight seal when used with appropriate sealing washers or bonding compounds, particularly in high-pressure systems common in Europe.

Metric Threads: Metric threads, used predominantly outside of North America, generally feature a thread angle of 60 degrees. This angle is common across most metric fittings, making them slightly sharper compared to BSP threads. They are straightforward to identify due to their widespread use in automotive and industrial applications globally.

NPT (National Pipe Tapered): NPT threads have a unique feature of a 60-degree thread angle but are tapered, which allows the threads to form a seal as they are tightened. The tapering and angle are designed to mesh tightly as the male and female threads are screwed together, using the thread itself to form a seal, which is enhanced by thread sealants.

Practical Tips on Measuring and Identifying Thread Angles

Use a Thread Gauge: The most straightforward method to determine thread angles is to use a thread gauge, which can directly measure the angle formed at the thread’s peak. Simply place the gauge against the thread; if it fits perfectly, you have found the correct angle.

Calipers and Micrometers: For a more precise measurement, use calipers or micrometers to measure the outer and inner diameters of the threads. Once you have these measurements, refer to a thread identification chart to determine the angle based on known standards.

Visual Comparison: Often, a trained eye can distinguish between the slightly different angles of Metric (60 degrees) and BSP (55 degrees) threads through visual inspection, especially when they have samples for comparison. This method is quick and useful in field conditions where precise instruments may not be available.

Consult Technical Specifications: When possible, consult the technical specifications of the fitting. Manufacturers often provide detailed diagrams and specifications, including thread angles, which can be invaluable for verification.

When to Contact the Manufacturer

Unusual or Custom Fittings: If the fitting in question is not standard or appears to be custom-made for specific equipment, manufacturer insights can provide necessary specifications and replacement details.

Obsolete or Discontinued Parts: When dealing with older or discontinued models, the manufacturer can often suggest modern equivalents or provide sources for obtaining rare parts.

Safety-Critical Applications: For fittings used in critical safety applications, such as aerospace or chemical processing, confirming specifications with the manufacturer ensures compliance with safety standards and regulatory requirements.

Complex Assemblies: In systems with complex integration of various fitting types, manufacturers can offer assembly diagrams and compatibility guidance to avoid errors in reassembly after maintenance or repair.

Conclusion

The ability to quickly and accurately identify hydraulic fittings in the field is a critical skill for technicians and engineers working in the maintenance and assembly of hydraulic systems. Professionals should keep abreast of industry standards and new developments. The tips and strategies outlined in this guide are designed not only to improve individual skills, but also to foster a culture of precision and safety that benefits the industry as a whole. If you are still in any doubt, feel free to contact Topa!

FAQ

What are the most common types of hydraulic fittings?

The most common types include JIC (Joint Industry Council), SAE (Society of Automotive Engineers), NPT (National Pipe Tapered), BSP (British Standard Pipe), Metric, and ORFS (O-Ring Face Seal).

How can I visually distinguish between JIC and SAE fittings?

JIC fittings have a 37-degree flare, and SAE fittings typically have a 45-degree flare. The difference in the angle of the flare is visually noticeable when compared side by side.

What is the best way to determine the thread type of a hydraulic fitting?

Use a thread gauge to measure the pitch and diameter of the thread. Comparing these measurements with a thread identification chart can confirm the type.

Can NPT and BSP threads be interchanged?

No, NPT and BSP threads should not be interchanged. NPT threads have a different taper and pitch compared to BSP threads, which can lead to leaks and thread damage if forced together.

Why is it important to identify hydraulic fittings correctly?

Correct identification ensures compatibility and seal integrity, which are crucial for preventing leaks and maintaining system pressure and efficiency.

What tools are essential for identifying hydraulic fittings in the field?

Essential tools include calipers for measuring dimensions, thread gauges for identifying thread types, and possibly a reference book or mobile app with visual identifiers.