How to Choose Hydraulic Hoses for Your Application

Selecting the right hydraulic hose is not merely a matter of inventory or convenience; it’s a critical decision that affects the efficiency, safety, and operational integrity of your hydraulic system. A poor choice can lead to system failures, frequent maintenance, and even safety hazards, disrupting your workflow and incurring unnecessary costs. Therefore, the objective of this comprehensive guide is to arm you with the essential knowledge you need to make an informed decision. We will delve into various factors such as application requirements, hose size, material composition, fittings, industry standards, and more. Each of these elements plays a pivotal role in determining the suitability of a hydraulic hose for your specific application.

Table of Contents

Understanding application requirements

The first step in choosing the right hydraulic hose before delving into a catalog or online store is to thoroughly understand the specific requirements of your application. This requires a multifaceted approach that takes into account factors such as pressure ratings, temperature ranges, and fluid compatibility.

Pressure rating

When it comes to pressure ratings, you need to distinguish between working pressure and burst pressure. Working pressure is the standard pressure at which a system operates, while burst pressure is the maximum pressure a hose can withstand before it fails. It’s critical to choose a hose with a working pressure rating that matches your system, but it’s also important to make sure that the hose can withstand occasional pressure surges without bursting.

Temperature

Temperature is another critical factor. Hydraulic systems typically operate in environments with varying temperature conditions. Whether your system is indoors in a controlled environment or outdoors exposed to the elements, the hose must be able to withstand the various temperatures encountered. This includes not only the ambient temperature but also the temperature of the hydraulic fluid flowing through the hose.

Fluid compatibility

Fluid compatibility is often overlooked, but it is critical to long-term performance. The inner tube of the hose must be compatible with the hydraulic fluid used in the system. Incompatibility can lead to corrosion, leaks, and premature hose failure.

Taking the time to analyze these application requirements will set the stage for the rest of the hose selection process. This initial evaluation will guide you in narrowing down your choices to ensure that the hose you select is not only right for your specific application but also performs well, optimizing performance and reducing risk.

Hose Size

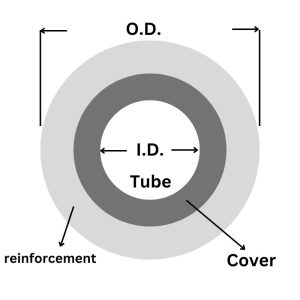

After understanding your application’s specific requirements, the next crucial step is to determine the appropriate hose size. This involves considering three main dimensions: the inner diameter (ID), the outer diameter (OD), and the length of the hose.

I.D.

The inner diameter is directly related to the flow rate of the hydraulic fluid. A hose with an ID that’s too small will restrict flow, causing a pressure drop and reducing system efficiency. On the other hand, an excessively large ID may lead to sluggish system performance. Therefore, it’s essential to match the ID with the flow rate requirements of your application for optimal performance.

O.D.

The outer diameter is often dictated by the space constraints of your system. In confined spaces, a hose with a large OD may not fit or may require additional modifications to your setup, adding unnecessary complexity and cost. Always measure the available space to ensure that the hose will fit comfortably without causing any obstructions.

Length

Length is another critical factor to consider. Hydraulic hoses can elongate or contract under pressure, so it’s vital to account for these changes when determining the length you need. Too short a hose can lead to tension, while too long a hose may result in slack, both of which can affect system performance and longevity.

In summary, selecting the correct hose size is not just a matter of matching numbers; it’s about understanding how these dimensions interact with your specific application. By carefully considering the inner and outer diameters and the length of the hose, you can make a selection that enhances your system’s efficiency, reliability, and overall performance.

Hose material

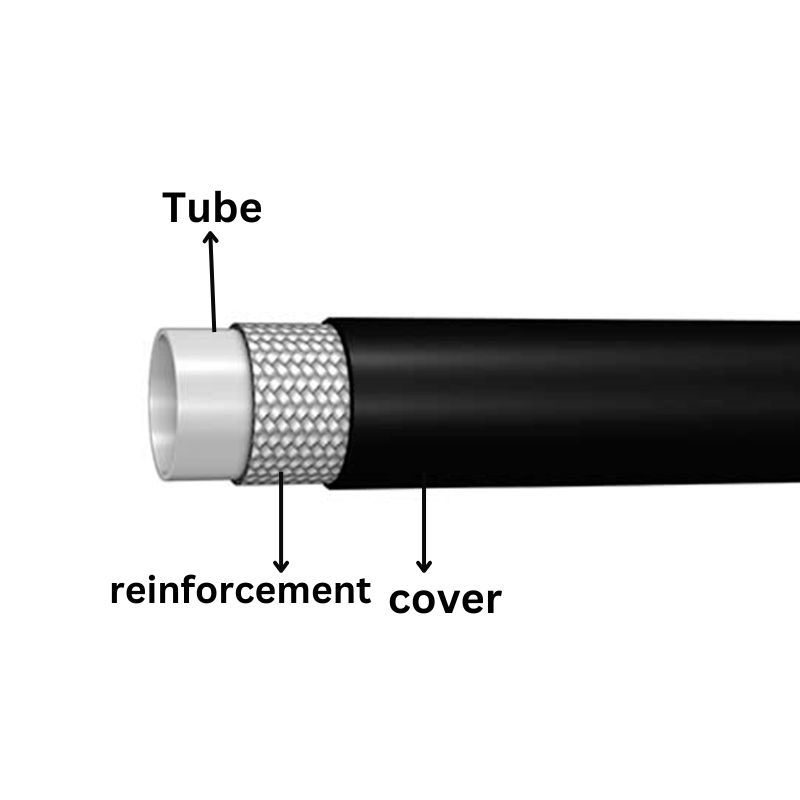

After determining the size specifications, the next focus should be on the material composition of the hose, including the inner tube, reinforcement, and outer layer.

Tube

First is the inner tube, whose material must be compatible with the hydraulic fluid being used. Common materials include nitrile, neoprene, and PTFE. Incompatible materials can degrade over time, leading to leaks, reduced efficiency, and ultimately system failure.

Fitting Types

Reinforcement layers provide strength and flexibility to the hose. Depending on the pressure requirements of your application, you can choose from several types of reinforcement layers such as steel wire braid, steel wire spiral braid, or textile braid. Steel wire braid is typically more flexible but less strong for low-pressure applications. Spiral steel wire hose, on the other hand, is designed for high-pressure systems and is stronger, but less flexible.

Fitting Types

The hose cover protects the hose from external factors such as abrasion, weather conditions, and chemical exposure. Commonly used cover materials include synthetic rubber, thermoplastic, or metal. Your choice should be consistent with the environmental conditions the hose will face, whether it’s exposed to sunlight, oil, or harsh chemicals.

Essentially, the material composition of a hydraulic hose is a balance between compatibility, strength and environmental resistance. From the inner tube to the cover, each component plays a vital role in the overall performance and longevity of the hose. By making smart choices in material selection, you are choosing a hose that not only meets but exceeds the requirements of your specific application.

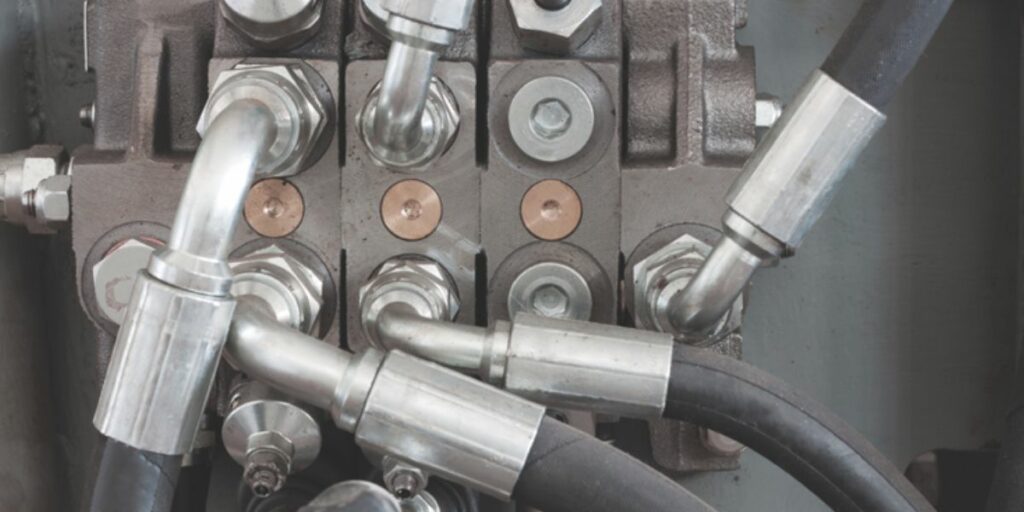

Hose fittings

After determining the hose material and size, the next step is to consider the type of fitting that will connect the hose to the rest of the hydraulic system. Fittings must be compatible with the hose and its connected components to ensure a safe and leak-free connection.

Fitting Types

There are several types of fittings available, such as JIC (Joint Industry Committee), NPT (National Pipe Thread), and ORFS (O-Ring Face Seal). Each type has its own advantages and limitations, so it is critical to select the type that best suits the system requirements.

Fitting materials

Fittings are usually made from materials such as stainless steel, brass, or carbon steel. When selecting a material, consideration should be given to its compatibility with the hydraulic fluid and the environmental conditions in which it will be used.

Compatibility

It is vital to ensure that the fitting is compatible with the chosen hose. Incompatibility can lead to weak points in the system, causing leaks and even catastrophic failure under pressure. Always refer to the manufacturer’s guidelines or consult an expert to confirm compatibility.

Installation and Assembly

Proper installation is just as important as the selection of the fitting itself. Incorrectly installed fittings can compromise the integrity of your hydraulic system. Always follow the manufacturer’s installation guidelines and consider using professional services for critical applications.

Paying due attention to the type, material, and compatibility of hose fittings is an important step in optimizing your hydraulic system. Proper selection and installation of fittings not only secures hoses but also improves the overall efficiency and safety of your system. This will ensure that you get the most out of your investment in terms of both performance and longevity.

Industry standards

After considering application requirements, dimensions, materials and fittings, it is critical to turn your attention to industry standards and codes. These guidelines serve as benchmarks for quality, performance and safety, ensuring that hydraulic hose meets or exceeds the standards required for the application.

SAE, EN and ISO Standards

Commonly followed standards include those set by the Society of Automotive Engineers (SAE), European Standards (EN) and the International Organization for Standardization (ISO). These standards outline minimum requirements for various aspects such as pressure ratings, dimensions and material quality.

Compliance Requirements

Depending on the industry and location, hydraulic hoses may have to meet specific compliance requirements. These vary from food-grade specifications for the food and beverage industry to flame-retardant requirements for mining or oil and gas applications.

Manufacturer specifications

When choosing a hydraulic hose, always refer to the manufacturer’s guidelines. These specifications are tailored to the design and material composition of the hose and will give you a complete understanding of the hose’s performance and service life.

Certification and Documentation

Ensure that the hose has the appropriate certifications showing that it has been tested and approved to meet the relevant industry standards. Not only is this reassuring, it’s also a quality assurance.

Cost-Performance Ratio

After ticking off the technical boxes, it’s time to consider the financial aspect of your hydraulic hose selection. While it might be tempting to opt for the cheapest option, it’s crucial to weigh the initial cost against the hose’s expected longevity and performance.

Initial Cost vs. Longevity

A low-cost hose may save you money upfront but could result in frequent replacements and increased maintenance, driving up the total cost of ownership. On the other hand, a more expensive, high-quality hose is likely to last longer and perform better, offering a more cost-effective solution in the long run.

Quality as a Non-Negotiable Factor

Quality should never be compromised for short-term savings. A subpar hose can lead to system inefficiencies, downtime, and even safety hazards, which could end up costing far more than the initial savings.

Calculating the Cost-Performance Ratio

To get a true sense of the hose’s value, consider calculating its cost-performance ratio. This involves dividing the total cost of ownership by the expected lifespan of the hose, giving you a per-year or per-month cost that can be compared across different options.

By carefully evaluating the cost-performance ratio, you’re not just making a purchase; you’re making an investment in the efficiency and reliability of your hydraulic system. This approach ensures that you’re not only meeting the immediate needs of your application but also securing its long-term success.

Vendor Selection

Once you’ve identified the specifications and cost considerations, the final step is to choose a reliable vendor to supply your hydraulic hose. This decision is just as critical as the technical aspects, as the right vendor can offer not only a quality product but also valuable support and services.

Reputation

Start by researching the vendor’s reputation in the market. Look for customer reviews, testimonials, or case studies that can provide insights into the quality of their products and customer service.

Availability

Check the vendor’s stock availability and lead times. A vendor with a well-stocked inventory can provide quicker delivery, reducing downtime in case of an emergency replacement need.

Support

Consider the level of pre-sales and after-sales support offered by the vendor. Expert guidance during the selection process and robust customer service afterward can make a significant difference in your overall experience.

Certifications and Quality Assurance

Ensure that the vendor adheres to industry standards and offers products with the necessary certifications. This is a strong indicator of quality and compliance, providing an additional layer of assurance.

By taking the time to evaluate potential vendors on these criteria, you’re not just buying a product; you’re establishing a partnership. A reliable vendor can offer ongoing support, timely deliveries, and quality assurance, contributing to the long-term success of your hydraulic system.

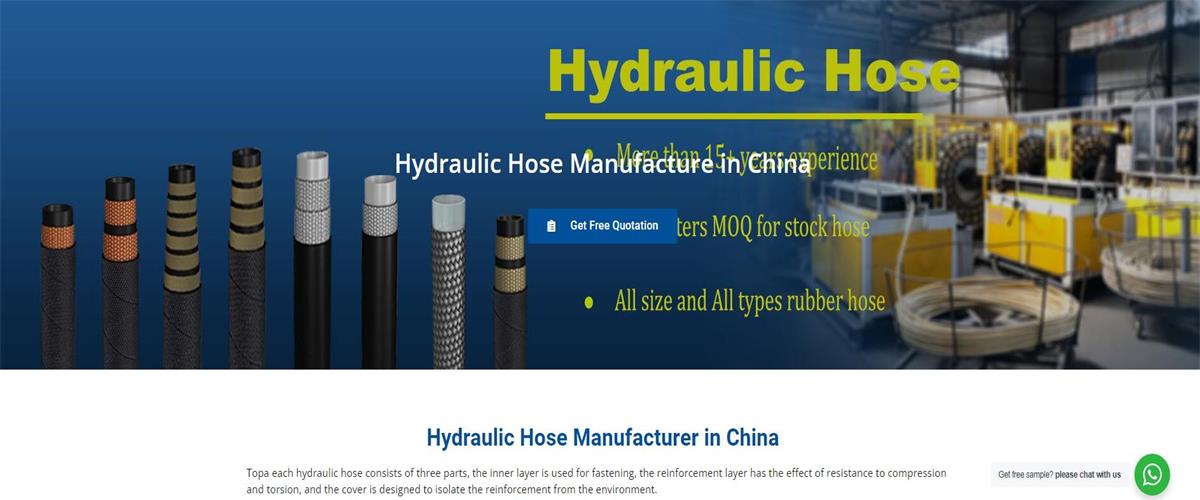

Why choose Topa

After presenting you with a comprehensive step-by-step process for selecting the ideal hydraulic hose, we introduce you to Topa hydraulic hose – the choice that embodies quality, performance and value.

At Topa, we understand the complexities and requirements of hydraulic systems. That’s why our hoses meet the highest industry standards, from pressure ratings and material composition to compliance with SAE, EN and ISO specifications. Our hoses offer the perfect blend of durability, flexibility and abrasion resistance to ensure your hydraulic system operates at peak efficiency.

Every Topa hydraulic hose undergoes rigorous testing and quality assurance processes to ensure it meets or exceeds industry standards. When you choose Topa, you’re choosing a product that’s built to last.

Our team of highly skilled professionals is ready to help you make the right choice for your specific application. From pre-sales advice to post-sales support, we’re with you every step of the way.

We believe that quality should not come at a price. Our factory direct model allows us to offer competitive prices without sacrificing the features that are most important to you.

We invite you to experience the Topa difference. When you choose Topa hydraulic hoses, you get a solution that delivers performance and peace of mind. If you have any questions or need assistance, please feel free to contact us. With just one Topa hose, you can have the best hydraulic system possible.

Conclusion

In conclusion, choosing the right hydraulic hose is a multi-dimensional decision that requires a deep understanding of various factors. These include your application’s requirements, hose dimensions, material composition, fittings, industry standards, cost considerations, and vendor reliability. Making an informed choice is not merely a short-term solution but a long-term investment in the efficiency and reliability of your hydraulic system. By following this guide, you’re setting the stage for a system that performs optimally, minimizes risks, and offers long-lasting benefits.