FAQ

What sizes of hydraulic tube assemblies are available?

We provide tubing in outer diameters ranging from 6 mm to 50 mm (or 1/4″ to 2″), with custom lengths and bends based on your requirements.

What materials are your tubes made from?

Our hydraulic tubes are available in carbon steel (ST 37.4 / ST 52), 304/316 stainless steel, and aluminum or copper for low-pressure applications.

What wall thickness options are offered?

We support Light (L), Medium (M), and Heavy (H) wall series to accommodate varying pressure ratings and mechanical strength.

What is the maximum working pressure for these assemblies?

Pressure ratings vary by material and size but can reach up to 6000 PSI for thick-walled carbon or stainless steel tubes.

Are the hydraulic tubes seamless or welded?

We primarily offer cold-drawn seamless hydraulic tubes to meet DIN 2391, EN 10305-1, and SAE J524 precision standards.

What surface treatments are available?

Tubes can be supplied with zinc plating, phosphate coating, powder coating, or natural stainless steel finish for corrosion resistance.

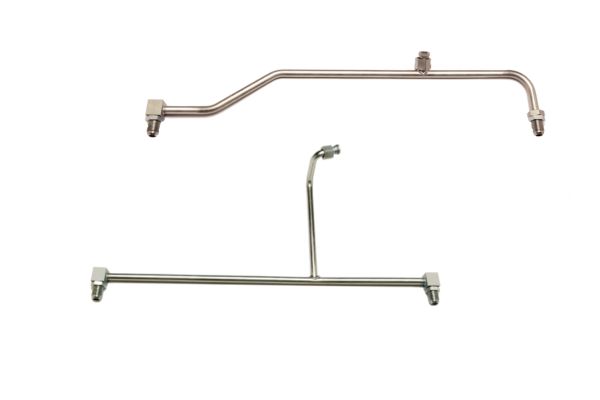

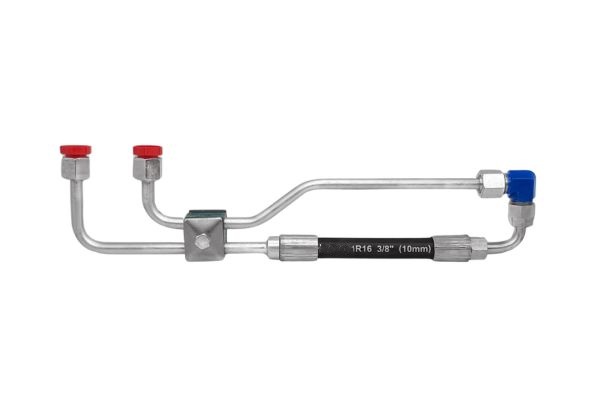

What type of ends and fittings are compatible?

Our tube ends support JIC, ORFS, BSPP, NPT, DIN 2353 compression, flare, or welded connections. Custom thread machining is also available.

Do the tubes meet international hydraulic standards?

Yes. Our tubing complies with ISO 8434-1, SAE J524, DIN 2391, and other global hydraulic fluid conveyance standards.

Are the tubes suitable for high-temperature environments?

Yes. Stainless steel tubes can operate up to +400°C, while carbon steel tubes are typically rated up to +120°C depending on surface treatment.

Can your hydraulic tubes be bent into complex shapes?

Yes. We use CNC mandrel bending for precise, multi-plane tube geometry while maintaining internal flow integrity and structural strength.