Hose Protection manufacturer

※ Fire proof

※ Abrasion resistant

※ Easy to operate

※ Multiple materials

Compatible Hose Protection manufacturer in China

The hose protector is used to wrap the hose and provide protection for the hose to prevent it from leaking or wearing out. And also can prevent damage to people and machines after the hose leaks. Topa offers a wide range of high quality hose protection, so if you have a requirement, please contact our staff for more information.

Product List

Hose protector exists in different types and materials, the most common protective sleeve is made of nylon. In addition, there are fire sleeve hose protector, hose protector sleeve, wire hose protector, hose protector spring and so on. And, we can also provide other kinds of hose protectors, you can check the picture below for details.

Nylon hose protector

Nylon hose protector is the most common type, which can reduce the external abrasion and damage to the hose.

Polyester textile hose sleeve

The polyester sleeve hose protector is made of polyester fiber and is resistant to high temperatures as well as abrasion.

Hose protector sleeve

The hose sleeve eliminates damage caused by extreme heat and wear.

Fire sleeve

The fire sleeve hose protector can protect the hose in high temperature, fire environment.

Hose protector wrap

The hose protector wrap protects against abrasion, impact and weather. It is resistant to acids, solvents.

Spiral guard hose protector

The spiral guard hose protector is ideal for use with hydraulic or pneumatic hoses.

Hose protection

The hose protector is used to wrap the hose and provide protection for the hose to prevent it from leaking or wearing out.

Wire hose protector

Wire hose protectors are commonly made of plastic. Easy and flexible to use.

Steel spiral hydraulic hose protector

The steel spiral hydraulic hose protector is made of metal and is corrosion resistant, pressure resistant and durable.

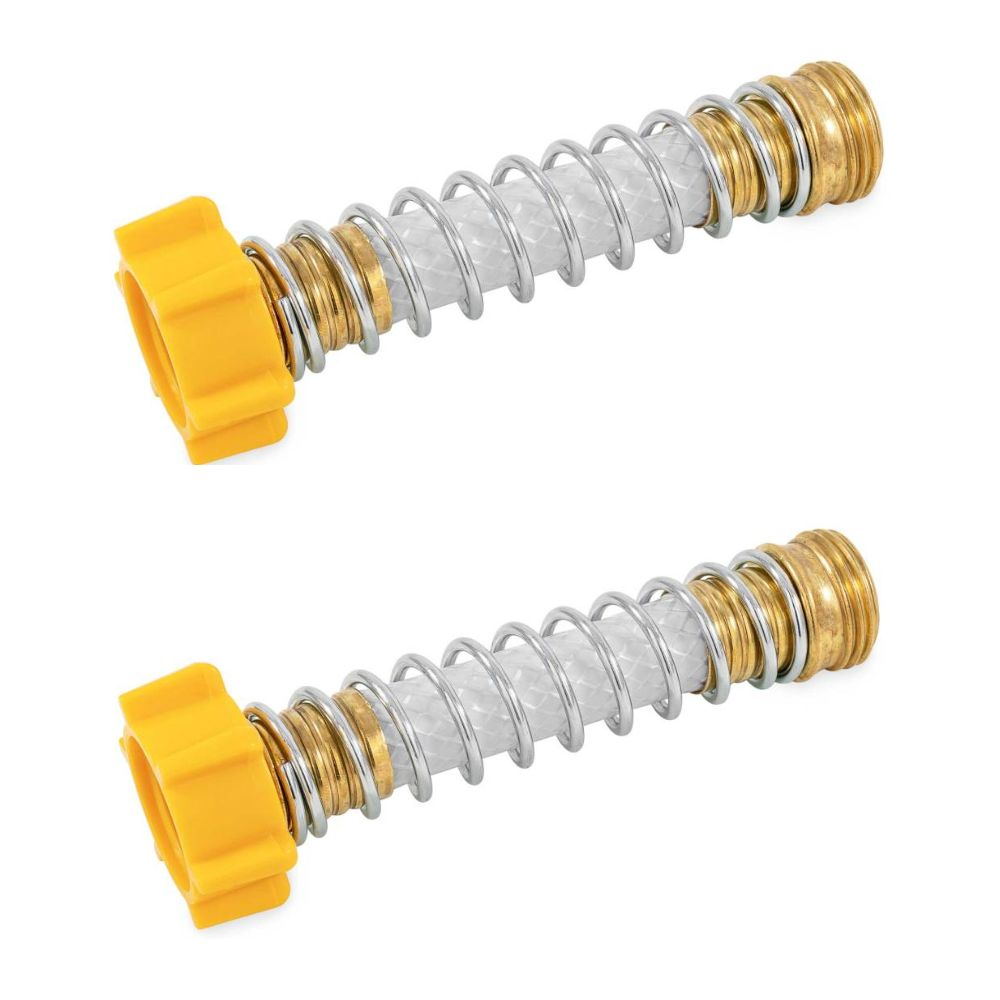

Hose protector spring

Hose protector springs are usually made of metal and can be used to enclose industrial hydraulic

Fabric heat shrink braided sleeving

Fabric heat shrink braided sleeving is mainly used for bundling and protecting cables.

PET expandable braided sleeving

PET Expandable Braided Sleeving is suitable for many applications and can be used to organize cables.

Plastic hose protector

Plastic hose protectors are usually wrap hoses for low-temperature, low-pressure environments.

Flexible hose protector

Flexible hose protectors are made of metal, plastic, silicone, etc. Flexible and durable.

Electric welding finger sleeve

Electric welding finger sleeve can be carried outside of gloves to prevent sparks from welding from causing injury to workers.

Spark plug sleeve

Spark Plug Sleeve insulates against high temperatures and is both durable and affordable.

Heat Shroud sleeve aluminized sleeving

Heat Shroud aluminized sleeves can be insulated from high temperatures to better protect cables, and hoses.

Turbocharger heat shield protection

The titanium fiber turbocharger heat shield protection provides better insulation from heat.

Golden aluminum foil fiberglass tape

Golden Aluminum Foil Fiberglass Tape can be wrapped around the hose where protection is needed, reducing the damage caused by heat and abrasion.

High silicon-oxygen fireproof cloth

High silicon-oxygen fireproof cloth is made of silica-containing thread braided to resist high temperatures and sparks.

Nylon hose sleeve with velcro

The protective nylon hose sleeve with Velcro is easier and more convenient to use and can be used in many applications.

Hose Protection video

We have a wide variety of hose protectors with great quality and detail. You can click on the video above to see the details of the hose protectors.

Topa manufacturer hydraulic fittings

We are hydraulic fittings manufacturer, we provide all types of hydraulic fittings. And if you want to know more information, please feel free to contact us.

Your reliable Hose Protection manufacturer

Topa offers different types of hose protectors in different materials, which can be used in many different environments. There are different types and materials of hose protectors, and the application range is very wide. Hose protection sleeves can be used in various applications of piping systems.

In addition, the advantages of the hose protector are also very significant:

1.Wear-resistant

2.Durable

3.Easy to bend

4.Easy to install

5.Complete range

6.Fair price

Why choose us

As a hydraulic parts company with extensive expertise, Topa is committed to providing every customer with a wide range of high quality hydraulic parts at excellent prices. In addition, we offer a wide range of hydraulic hoses, hydraulic hose protectors, ball valves, pipe shrinkers, and other industrial products.

We can also provide each customer with.

1.Perfect process

We have a complete process from inquiry, order, production and shipping, after the customer has completed the order, and we will arrange the production and shipping as soon as possible, so that you can get your goods as soon as possible.

2.Serious working attitude

Every Topa staff will serve every customer with strict and serious working attitude to provide you with a comfortable buying environment.

3.Suitable price

Most of our products are of good quality and low price.

4.A wide range of categories

Topa offers a wide range of fittings, hoses, and other accessories in a variety of styles and materials to meet most people’s needs.

Application

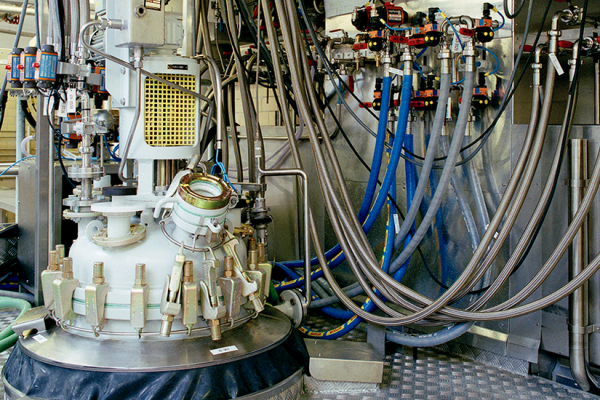

Hose protectors have a wide range of applications, they can be used in many systems where pipelines exist, such as factories, oil and gas, agriculture, chemical transportation and other industries.

Manufacturing

Topa offers top of the line hose protectors that play a major role in the manufacturing industry, protecting hoses and cables from abrasion, heat and damage, and making it easier for workers to identify the hoses they are looking for.

Construction

In the construction site, the hose and cable is easy to be worn and damaged because of the external environment, and after the use of hose protection sleeve, the chance of damage is greatly reduced, the use of hose and cable life has been extended, saving part of the expenditure.

Factory

Most factories use hoses and cables, so protective sleeves are an essential need. Hose protection sleeve not only can extend the life of the hose and cable, but also can protect the workers from the injury caused by the leakage of the object in the broken hose.

Hose Protection quality control

For each Topa product, multiple checks such as manufacturing monitoring, quality testing and packaging inspection are carried out to ensure the quality and level of the product.

FAQ

What is a hose protector?

The hose protector is used to wrap the hose and provide protection for the hose to prevent it from leaking or wearing out. And also can prevent damage to people and machines after the hose leaks.

what is a hose protection used for?

There are different types and materials of hose protectors, and the application range is very wide. Hose protection sleeves can be used in various applications of piping systems.

How many types of hose protector?

Hose protector exists in different types and materials, the most common protective sleeve is made of nylon, in addition, there are fire sleeve hose protector, plastic hose protector, wire hose protector, steel hydraulic hose protector spiral and so on.

What are the advantages of hose protector?

GHose protection sleeve can reduce the external environment on the hose abrasion, pollution and the impact of extreme weather, but also to reduce the hose breakage of the external environment, people and machinery damage.

Is the hose protector fireproof?

There is a special kind of protection sleeve called fire sleeve, this kind of protection sleeve can withstand high temperature and fire.

How to install hose protector?

The wrap-around hose protector can be wrapped directly onto the hose to be protected, easily and quickly. Some other protectors can be wrapped directly onto the hose.

Why do hoses need hose protectors?

Hydraulic hose working environment is generally harsh, there will be high temperature, extrusion, wear and tear, or twisted conditions, and hose protection sleeve can provide some protection to extend the service life of the hose.

Can I reuse the hose protector?

It is not recommended to reuse the hose protection sleeve, because, after abrasion, high temperature, and other factors, the protective strength of the sleeve has been reduced, can not better protect the hose.

Can I get free sample?

If our products are in stock, we can provide you with some free samples, and you only need to provide the shipping cost.

How long does it take to ship?

With no external influence, we will arrange production and shipping as soon as possible after you place a successful order.