Whip Check manufacturer

※ No rust

※ Corrosion-resistance

※ Easy to operate

※ Durable

Compatible Whip Check manufacturer in China

Topa can provide a variety of different types of whip checks in different materials. Whip checks are a safety device, they hold the hose in place and prevent it from being thrown out after disengagement. And if you have any question of whip check or other products, please feel free to get in touch with us.

Product List

From the use of objects, the whip check has two types of hose to hose, hose to equipment; from the material, there are metal, nylon and PVC whip check. Topa is committed to meeting the needs of our customers. If the products we offer do not satisfy you, please contact us, we can also provide custom services.

200 psi whip check

Whip checks are generally made of metal and can withstand pressures of no more than 200 psi.

Cable whip check

Cable whip check is generally made of metal, easy to install, corrosion-resistant and wear-resistant.

Hose to hose whip check

Hose to hose whip check attached to the hose fixed to prevent the hose from detaching to cause injury.

Hose to eauipment whip check

The hose to equipment whip check is attached to one end of the hose and the other end is on the equipment to prevent the hose from falling off and causing injury.

Cable pulling grip

The cable pulling grip is reusable and can be used with cables, fiber optic cables, wire ropes, etc.

Whip stops

Whip stops are usually made of woven steel and hold the broken pipe firmly to prevent it from coming out and causing injury.

Steel wire rope

Steel wire ropes are made of braided steel wire and can be used in many applications.

Heavy duty car towing drawbar rope

Heavy Duty Car Towing Drawbar Rope is used to tow the broken down vehicle, but do not move too fast to prevent accidents.

Red round slings

Red iron choker can also be called red iron slings, used to prevent the hose from falling off after causing injury.

Nylon whip check

The nylon whip choker can be tightly pressed against the hose in the event of a failure and is a good alternative to a whip check.

Hose hobble

Hose hobble can be on the hose or hard pipe wall, can prevent the hose from throwing out.

Breakaway trailer cable

The Breakaway Trailer Cable connects the brake system to your trailer and prevents the trailer from unhooking.

Hosebun

The hosebun is designed to suspend the hose and prevent it from kinking and distorting.

Whip Check video

This video is about Topa’s whip check, which shows various details, please click to check it out.

Topa manufacturer hydraulic fittings

We provide all types of hydraulic fittings, we accept custom and personalized manufacturing, so if you want to know more information, please feel free to contact us.

Your reliable Whip Check manufacturer

The whip check can be extended to the entire hose joint to provide safety for the hose. When a hose is accidentally disconnected, it can be thrown outward due to the pressure inside the pipe, causing injury to people and machinery. The presence of whip checks, on the other hand, greatly reduces this risk and protects personal safety and property.Topa offers various styles of whip checks, and many advantages exist for our products: 1. Corrosion resistance

- Corrosion resistant

- Not easy to rust

- Not easy to wear and tear

- No additional tools required

- Easy to install

Why choose us

As a company specialized in providing hydraulic parts, Topa has a large variety of hydraulic parts. Our hydraulic fittings are available in different threads, sizes and materials; hoses are also available to meet various needs; in addition to this, we can also supply industrial hoses, cylinders, constrictors, ball valves, etc.

We also have many advantages:

- High quality products

Our products are of high quality and can meet the needs of most customers.

- Rigorous working attitude

Our staff will treat customers with strict and serious attitude to provide a comfortable buying environment for customers.

- Fast shipping

After the customer’s order is successful, we will arrange the shipment directly for the goods in stock, and we will arrange the production and then shipping for the products without stock as soon as possible.

4.Customized service

If customers have special product requirements, we can produce according to your needs.

Application

Whip check does not require tools to assist in installation and is easy to operate; it is corrosion resistant and not prone to rust; it is less expensive and extremely practical. And whip checks can be used in plants, oil and gas, construction and automotive.

Industry

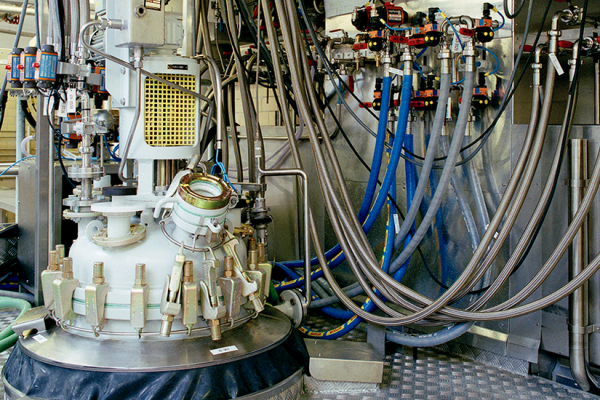

Whip checks also play an important role in industry, where hoses in factories need to be restrained and protected with whip checks. Different hoses in a factory require different whip checks, but they all work well to prevent accidents from happening.

Oil and Gas

In the oil and gas sector, pipelines are essential installations. Whip checks, on the other hand, play a non-negligible role in pipeline systems, and they can effectively reduce personal injury as well as property damage caused by accidental detachment of pipelines.

Construction

In the construction industry, whip checks can be used on pipes to reduce accidents caused by pipe shifting. Topa's whip checks are resistant to wear and corrosion and are easy to install, making them ideal for use in environments such as construction sites.

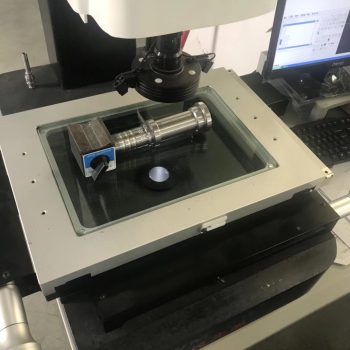

Whip Check quality control

For each Topa product, multiple checks such as manufacturing monitoring, quality testing and packaging inspection are carried out to ensure the quality and level of the product.

FAQ

What is a whip check?

Whip checks are a safety device, they hold the hose in place and prevent it from being thrown out after disengagement.

What is the purpose of the whip check?

The hoses, after accidental detachment, can be thrown outward due to the pressure inside the pipe, causing harm to people as well as machines. The existence of whip check, on the other hand, greatly reduces this risk and protects personal safety as well as property.

Where can the whip check be used?

Whip checks can be an effective way to provide safety assurance for hose pipe systems. Whip checks can be used in plants, oil and gas, construction and automotive.

What are the advantages of whip check?

Whip check does not require tools to assist in installation and is easy to operate; it is corrosion resistant and not prone to rust; it can provide a safe working environment, is less expensive and extremely practical.

What are the materials for whip check?

Usually, whip checks are made with metal, such as galvanized steel. But sometimes there are materials such as nylon or PVC.

How to install whip check?

The whip check can be installed with your bare hands by removing the ring on one side, installing it on the hose, and tightening it. The other side also follows the same procedure and can be installed to another section of hose or to a fixed point. If you need better results, you can pad the rubber ring to prevent slippage.

What is the maximum pressure of whip check?

The most suitable pressure range for whip inspection is within 200psi.

What should you know about using whip check?

Use the whip check to pay attention to: regularly check the wear or aging of the whip check; release the pressure in the pipe before replacing it, and then remove it; after a failure, the repair is completed to replace the new whip check again.

What are the types of whip check?

From the use of objects, the whip check has two types of hose to hose, hose to equipment; from the material, there are metal, nylon and PVC whip check.

Can I have my own customized product?

Yes, we can supply logo Print and package desiged based in our MOQ.