Description

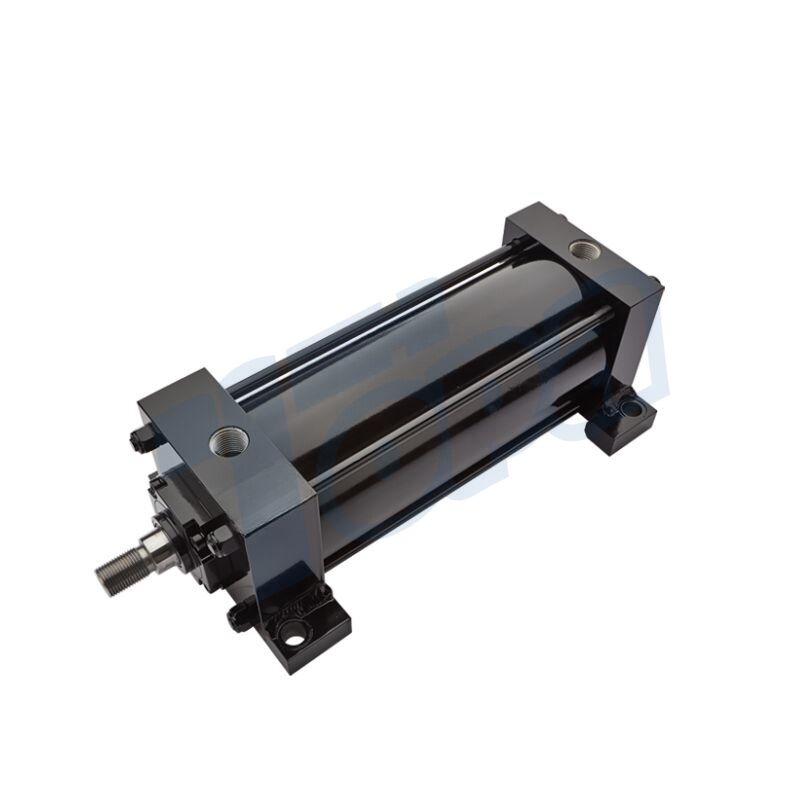

For high-pressure applications, our HP Series high-pressure hydraulic NFPA cylinders stand out with their rugged design.

Features

NFPA hydraulic cylinders are manufactured from high-strength metals to handle the rigors of high-pressure environments. This material not only provides the necessary strength, but also reduces wear and tear and the effects of external elements.The HP series cylinders are available in a wide range of working pressures to meet a variety of industrial needs.

Topa’s HP series cylinders are available in a variety of stroke lengths to meet the specific needs of each application. So our cylinders are capable of both short distance precision movement applications as well as wide reach tasks.

Advantages

High-Pressure Operation: Engineered to work efficiently across a broad pressure range, suitable for rigorous industrial tasks.

Versatility: Available in multiple stroke lengths to accommodate diverse application needs.

Standardization: NFPA compliance ensures compatibility with a wide range of equipment and easy integration.

Customization: Offers options for different seals and mountings to meet unique operational requirements.

Applications

Manufacturing: Utilized in high-pressure pressing, clamping, and assembly operations.

Mining: Essential for drilling and excavation equipment that operates under high pressures.

Aerospace: Applied in testing and assembly rigs where precision under high pressure is critical.

Marine: Used in steering systems and lifting equipment on ships where robustness is required.

Agriculture: Employed in advanced tractors and harvesters for lifting and loading tasks.

High Pressure Hydraulic NFPA Cylinders (HP Series)

The production of the HP Series high pressure hydraulic NFPA cylinders is a rigorous process at Topa’s manufacturing facility. We select high-strength steel that can withstand high pressures to ensure the performance of each cylinder. During fabrication, we use state-of-the-art CNC machines to cut and shape the steel. Each component is designed to meet strict NFPA standards.

Next, technicians assemble each component to ensure a tight seal. Each cylinder is thoroughly pressure tested to ensure they can withstand high-pressure environments.

When your operation requires a high pressure solution, contact us and let us make the best hydraulic cylinder for you.

Topa’s customization process for high-pressure hydraulic NFPA cylinders (HP Series) is designed to meet the specific needs of our customers, ensuring that each cylinder performs as expected.

Consultation: We begin with a detailed discussion with the customer to understand their unique requirements, including pressure needs, application and environmental conditions.

Design Customization: Our engineering team then custom designs the cylinder, adjusting dimensions, material selection, and seal type to the customer’s specifications.

Material Selection: We choose high-grade steel and durable seals to ensure that the cylinders can withstand high-pressure environments.

Precision Manufacturing: Utilizing state-of-the-art CNC technology, we manufacture each component to the customer’s exact specifications for a perfect fit and optimal performance.

Quality Testing: Customized cylinders undergo rigorous testing, including pressure and leakage tests, to ensure they meet NFPA standards and customer expectations.

Contact us today to get started on a cylinder that is perfectly suited to your specific needs.