In a hydraulic system, adapters are important components that connect the various hoses, tubes and pipes in the hydraulic system. They are critical to the smooth, efficient flow of hydraulic fluid and the overall performance of the system. Whether you’re a seasoned professional in the hydraulics industry or a zero-seller looking to break into the business, understanding the nuances of adapters can add tremendous value. This comprehensive guide will take you through everything you need to know about hydraulic adapter.

Adapters are specialized connectors that are used to seamlessly join various types of hoses, tubes and pipes in a hydraulic system. This type of connector plays a vital role in ensuring that the different components in the system can work together and facilitate the efficient flow of hydraulic fluids. The adapter acts as a bridge, both to allow fluid to flow between different components and to change the direction of fluid flow. It is an indispensable component that simplifies connections and improves the overall performance of a hydraulic system.

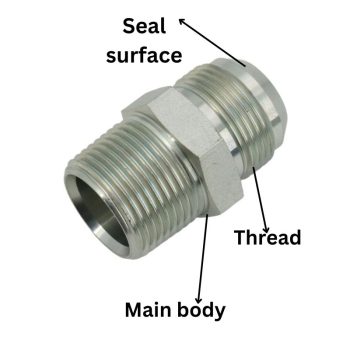

Main Body: It is the backbone for the adapter. The dimensions of standard adapters are fixed, but they can also be tailored to the components you want to connect. Whether you are connecting a hose to a tube or a tube to another tube, the shape of the main body adapts perfectly to these components.

Threads: The threads on the adapter are spiral ridges that, when twisted into place, ensure that the adapter locks securely in place. That way, it won’t wobble or pop off under pressure.

Sealing Surface: This is the safety guard of the adapter. It prevents leaks by forming a tight seal when you connect it to another component. The sealing surface is critical to maintaining a high-performance, leak-free system.

Hydraulic systems are like jigsaw puzzles. Let’s say you have different hydraulic components that all need to fit together just right. But what happens when two parts don’t match? That’s where hydraulic adapter fittings come in. So let’s take a deeper look at the types of adapters and how they build high-performance hydraulic systems.

First up is the coupling. Imagine there are two pipes, how do you connect them? The coupling is the answer. Couplings have female threads at both ends and can connect two identical male parts so that fluid can flow smoothly from one to the other. A coupling with different sizes at each end can be called a reduction coupling, which connects two fittings of different sizes. Standard couplings have stop zones inside, called internal stops, which prevent the pipe from being inserted too deeply and affecting the function of the connection.

A bushing is similar to a close nipple fitting, but it has threads on both ends. Bushings have larger male threads and relatively small female threads. Let’s say you have a large opening but need to fit a smaller part into it. A bushing will help you with this.

Sometimes you need to connect two fittings together. This is easily accomplished by using a fitting. It is a short piece with threads on both ends. By screwing one end into the first fitting and the other end into the second fitting, the fittings can be connected! If it has continuous uninterrupted threads, it is a close nipple.

Now, what if you have different parts that may need to be taken apart later? The union is the perfect adapter for you. A union is similar to a coupler, but with differences. It allows you to connect different parts, but also allows for easy disassembly. So if you need to replace or maintain a part, you can easily remove it without disassembling the entire system.

Reducing couplings have two ends: a larger one for larger pipes and a smaller one for smaller pipes. When these two ends are inserted into their respective pipes and tightened, hydraulic fluid can flow seamlessly between the two differently sized components.

Sometimes you need to change the direction of flow in your hydraulic system. Maybe you want to make a 90-degree or 45-degree bend. An elbow adapter can help you do just that. It allows you to change the direction of fluid flow, making your system more flexible. If the two ends of the fitting are different sizes, it is a reducer elbow fitting.

Tee adapters allow fluid flow to be split into two directions, or the two directions can be combined. Common tee ports have the same size threads, but of course, there are tees with different thread sizes. And the types of threaded ports of tees can also be different types.

Cross adapters are also called four-way fittings. That is, a cross fitting has four ports, each of which is threaded. Cross adapters allow fluid to be split into three different directions.

When it comes to adapters, materials are more than just a minor detail; they change the rules of hydraulic system use. The material you choose affects the longevity, rust resistance, and strength of your adapter.

Carbon Steel

Carbon steel is strong, which means it can withstand a lot of pressure. But beware of rust. Over time, carbon steel can corrode, especially when exposed to moisture.

Stainless Steel

Next up is stainless steel. This material is a champion of corrosion resistance. If you’re worried about rust, it’s your go-to choice. The downside is that it is more expensive than carbon steel.

Brass

Brass material is resistant to heat and corrosion. If you want both strength and rust resistance, brass is a good middle ground.

Let’s talk about international standards for hydraulic fitting adapters. You may ask, what does this have to do with anything? These standards for hydraulic adapters are what various countries have developed to ensure that hydraulic systems function properly. Here, we will broadly analyze the three main standards: ISO, SAE, and EN standards.

ISO (International Organization for Standardization)

First of all, there is ISO, a standard that is important on a global scale. It sets high requirements for quality and safety. When you see “ISO certified” you know you have a quality product. The fittings will be rugged, durable and fit perfectly to keep your hydraulic system in top shape.

SAE (Society of Automotive Engineers)

The SAE standards come from the United States and are aimed at mobile machinery such as automobiles and tractors. If you work in the automotive field, SAE is your standard of choice. It ensures that your adapter is as rugged as your machine.

EN (European Standard)

Finally, there’s EN. It’s a European standard that focuses on consistency. en ensures that every adapter is built the same way every time. This means there is less chance of a fault that could damage the hydraulic system.

When you’re setting up or maintaining a hydraulic system, different hydraulic equipment requires different kinds of connections, and how you connect adapters can make or break an operation. Let’s take an in-depth look at the main connection methods for hydraulic adapter and learn about their advantages and disadvantages.

Threaded connections are the most common type of connection. Common adapters are available with different types of threads, such as JIC, SAE, JIS, BSP, NPT, and ORFS. because the threaded connection is the most common connection, it is usually the most cost-effective and easy to install. Installation is simply a matter of screwing the adapter into place. But remember, torque is key. If it’s tightened too tightly or too loosely, it can lead to leaks. Therefore, it is important to torque it just right so that leak-free operation goes smoothly.

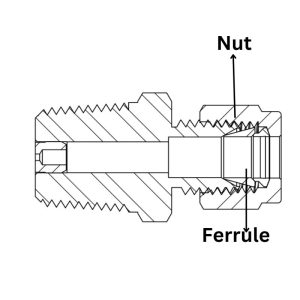

Compression fittings consist of a fitting body, ferrule, and crimp nut, and include double and single ferrule fittings. Compression fittings are preferred for high-pressure applications. These fittings utilize force to hold the connection in place and are therefore very reliable under pressure. Therefore, if you work in an environment that involves the movement of high-pressure fluids, compression fittings are the best choice for you.

Push-in connections are the best choice for quick and easy assembly. You simply push the adapter into the receiving end and secure it with the appropriate clamp. However, they are not suitable for all situations, especially high pressures or temperatures. They are best suited for light to medium-duty applications.

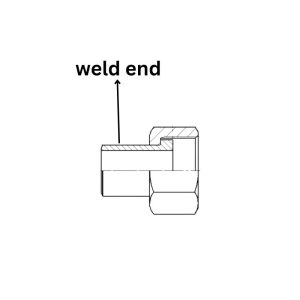

Welded connections are the use of different solder to fix the adapter to the hydraulic application. They are permanent and therefore very robust and reliable. Once soldered, these adapters will not come off or move easily. What are the disadvantages of soldered connections? They are difficult to remove, so you want to make sure that the hydraulic system doesn’t need to be disassembled later.

You have found the right adapter and chosen the best connection method. The next thing to do is to understand the hydraulic fitting sealing method. A solid seal is the final step in ensuring a safe and efficient hydraulic system. Let’s take a look at the common sealing methods – O-rings, washers, and thread sealants.

O-Rings

First, there are O-rings. These round rubber seals fit snugly into grooves and prevent leaks. They come in a variety of materials such as NBR, EPDM, and PU. o-rings are inexpensive, easy to install, and work well under pressure. You’ll often find O-rings in high-pressure environments where a good seal is essential.

Gaskets

Next, let’s talk about washers. These flat seals sit between two surfaces and prevent fluid leakage. They come in various materials such as rubber, metal, or a mix of both, each with advantages and disadvantages. For example, metal washers are durable, but may not be the best choice for uneven surfaces. And some products are available in gasket sets. Therefore, you’ll want to choose a gasket based on your specific needs.

Thread Sealants

Thread sealant can be considered the “glue” of threaded connections. Apply it to the threads before screwing the components together. The sealant will fill the gap, making it difficult for liquid to escape. They are perfect for jobs that require a quick and secure seal. They make up for the lack of sealing in some threads, making them a relatively used hydraulic fitting sealant.

When working with hydraulic systems, you will encounter various types of fittings. Two of the most common are hose fittings and adapters. While they may seem similar, they serve different purposes.

Simply put, hose couplings serve one purpose: to connect hoses. Whether it’s to extend the length of a hose or to connect a hose to a machine, these fittings are specialized for hose-to-hose or hose-to-machine connections. They are usually used for specific sizes and types of hoses and are therefore less flexible.

On the other hand, adapters are the jack of all trades in the connector world. They can connect different types of components such as fitting to fitting, hose to tube or tube to tube. The design of adapters allows for more versatility, making them invaluable in complex hydraulic systems.

Sizing a hydraulic system is critical. Choosing the wrong fitting size can lead to a variety of problems ranging from small leaks to complete system failure. Let’s take an in-depth look at why accurate sizing is so important and how you can ensure proper sizing.

Selecting the Correct Size

Refer to the manufacturer’s guide: Always check the manufacturer’s specifications for each part first.

Understand system requirements: Different systems have different pressure and flow requirements. Make sure the dimensions meet these requirements.

Double-check measurements: It’s a good idea to double-check dimensions before finalizing an order.

Consult a professional: If you’re not sure, consult a professional or customer support. It’s better to take more time to confirm than to deal with the problem later.

Use calipers for accuracy: When measuring parts, using calipers can provide more accurate dimensions than a regular tape measure.

Metric standard(60°) | Americal standard(60°) | British standard(55°) | ||||||

Thread No. | External | Thread No. | External | Thread No. | External | |||

Max | Min | Max | Min | Max | Min | |||

M10*1 | 9.97 | 9.79 |

|

|

| G1/8″*28 | 9.73 | 9.51 |

|

|

| 7/6”-20 UNF | 11.08 | 10.87 |

|

|

|

M12″1.5 | 11.97 | 11.73 |

|

|

|

|

|

|

|

|

| 1/2″–20 UNF | 12.67 | 12.46 |

|

|

|

|

|

|

|

|

| G1/4″-19 |

|

|

M14*1.5 | 13.97 | 13.73 | 9/16″-18 UNF | 14.25 | 14.03 |

|

|

|

M16*1.5 | 15.97 | 15.73 |

|

|

|

|

|

|

|

|

|

|

|

| G3/8″-19 | 16.66 | 16.41 |

|

|

| 11/16″-16 UN | 17.43 | 17.19 |

|

|

|

M18*1.5 | 17.97 | 17.73 |

|

|

|

|

|

|

|

|

| 3/4″–16UNF | 19.01 | 18.77 |

|

|

|

M20*1.5 | 19.97 | 19.73 |

|

|

|

|

|

|

|

|

| 13/16″-16UN | 20.60 | 20.35 | G1/2″-14 | 20.96 | 20.67 |

M22*1.5 | 21.97 | 21.73 | 7/8″–14UNF | 22.18 | 21.92 |

|

|

|

|

|

|

|

|

| G5/8″-14 | 22.91 | 22.63 |

M24*1.5 | 23.97 | 23.73 |

|

|

|

|

|

|

|

|

| 1″-14UNS | 25.35 | 25.10 |

|

|

|

|

|

|

|

|

| G3/4″-14 | 26.44 | 26.16 |

M27*1.5 | 26.97 | 26.73 | 1 1/16″-12 UN | 26.94 | 26.65 |

|

|

|

M27*2 | 26.96 | 26.68 |

|

|

|

|

|

|

M30*1.5 | 29.97 | 29.73 | 1 3/16″–12 UN | 30.12 | 29.83 |

|

|

|

M30*2 | 29.96 | 29.68 |

|

|

|

|

| |

hydraulic adapters size chart

Automotive

In cars and trucks, adapters are essential. They help connect various components such as brake lines and power steering systems.

Industrial

In factories and production lines, adapters help connect mechanical and hydraulic lines. They play an important role in automating processes, making work easier and more efficient.

Agriculture

In agricultural equipment such as tractors and harvesters, adapters are invaluable. They facilitate fluid flow, making machinery more efficient and less likely to break down.

Aerospace

The safety of airplanes and spacecraft is of paramount importance. Adapters here must meet stringent standards. They play a role in systems from hydraulics to fuel lines, ensuring that everything runs smoothly.

Marine

Boats and ships also rely on hydraulic adapter connectors. They are commonly used in steering systems and to operate winches. Due to the harsh saltwater environment, quality adapters are usually corrosion resistant.

Hydraulic pipe adapters are more than just connectors; they are key components that hold hydraulic systems together. Understanding the types, mater,ials and connection methods of adapters is critical for a salesperson, maintenance professional,onal, or distributor in the hydraulics industry. Accurate sizing and material selectaren is also critical to system longevity and efficiency. With the right knowledge and proper selection, hydraulic adapters can truly be the unsung heroes of hydraulic operations. As your trusted supplier, Topa Hydraulics is your one-stop solution for all your hydraulic product and component needs, ensuring quality and affordability every step of the way.