It is critical to understand the mechanics of hydraulic quick couplings.The term “Brinelling” specifically refers to indentation or wear that occurs on the surface of a coupling. This is usually due to excessive loads or stresses being placed on the metal surface, resulting in reduced functionality or failure. Properly recognizing the signs of Brinelling and taking preventative measures can prevent potential system failures and ensure safe and efficient operation. This guide is intended to provide a comprehensive understanding of Brinelling and its effects, as well as best practices for managing and preventing Brinelling in quick couplings.

Quick couplings, integral to efficient hydraulic systems, consist of several critical components, each designed to fulfill a specific function. The main structure, known as the body, serves as the housing for all internal components, ensuring durability and structural integrity. Within this body lies the valve, often designed as a ball or poppet valve, which is pivotal in controlling the flow and direction of the hydraulic fluid. The locking mechanism is another crucial component, offering security and stability to the coupling connection. These seals, typically made from robust materials like rubber or PTFE.They ensure that the hydraulic system maintains its efficiency and reliability, even under high-pressure conditions.Together, these components work in unison to ensure the hydraulic quick coupling’s effective and safe operation, forming the backbone of countless industrial and mechanical applications.

In quick couplings, each component plays a vital role in ensuring efficient operation. Valves are at the heart of the system, effectively managing fluid flow. When the coupling is engaged, the valve opens, allowing hydraulic fluid to flow seamlessly, ensuring uninterrupted system operation. Conversely, when the coupling is disconnected, the valve closes quickly, creating a tight seal that prevents any fluid leakage, thus maintaining the integrity of the system. Whether ball-locked, pin-locked or threaded, this device provides a reliable connection that withstands the operating pressures and vibrations inherent in hydraulic systems. These components work in harmony to allow the hydraulic system to function properly under a variety of conditions.

Various quick couplings are tailored for specific applications and pressure ranges. Push-to-connect couplings offer easy, tool-free connections. Thread-to-connect couplings, suited for high-pressure scenarios, provide robust connections. Flat-face couplings, ideal for clean environments, minimize fluid loss and contamination. Each type is designed for specific situations, highlighting the importance of selecting the appropriate coupling for your needs.

Brinelling in hydraulic quick couplings is a phenomenon where the metal surfaces experience deformation, characterized by dents or indentations. This wear and tear is not just a superficial issue but is indicative of underlying structural stress within the coupling mechanism. The term originates from the Brinell hardness test, which measures the indentation hardness of materials.

Brinelling is typically triggered by several factors. One primary cause is excessive vibration, which can occur during the operation of hydraulic machinery. When these vibrations are persistent, they lead to repetitive stress on the coupling surfaces, causing the metal to deform. Another significant cause is high-impact loads, especially in industrial settings where hydraulic systems are under constant heavy-duty use. Improper installation and alignment of the couplings can also contribute significantly to Brinelling, as misaligned parts endure uneven stress distribution, accelerating wear and tear.

The consequences of Brinelling on the functionality of hydraulic couplings are multi-faceted and significant. The primary concern is the compromised sealing ability due to the deformed surfaces, leading to potential fluid leakage. This leakage can not only reduce the efficiency of the hydraulic system but also poses environmental and safety risks. Furthermore, Brinelling can result in increased friction within the coupling mechanism, reducing its operational smoothness and increasing the energy required for operation. Over time, these issues escalate maintenance requirements, operational costs, and the likelihood of system failures.

Brinelling’s impact extends beyond the physical wear of components; it can disrupt the overall hydraulic system’s reliability and efficiency. Therefore, understanding and preemptively addressing Brinelling in hydraulic couplings is vital for maintaining the integrity and longevity of hydraulic systems across various applications, ensuring safe and efficient operations.

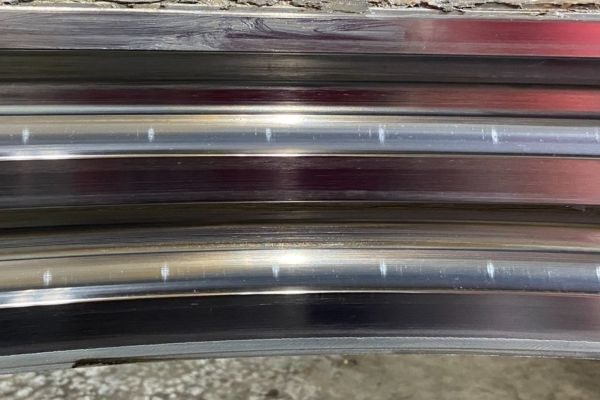

The first step in identifying Brinelling in hydraulic systems is recognizing its distinct signs. These typically manifest as visible indentations or surface deformations on the metal parts of the coupling. In more advanced stages, these indentations can become quite pronounced, leading to noticeable roughness or irregularities on the surface. Sometimes, these deformities are accompanied by an increase in friction during coupling operation, indicating significant wear.

Effective inspection is key to early detection of Brinelling. Regular visual inspections are the most straightforward technique, involving a close examination of the coupling surface for any signs of indentation or wear. For more precise measurements, technicians might use tools like micrometers or depth gauges, which can accurately measure the depth and extent of any surface deformations. In settings where more advanced analysis is required, techniques like ultrasonic testing can be employed, offering a non-destructive way to assess the internal condition of the couplings.

Regular maintenance checks are vital for early detection and prevention of Brinelling. These checks should include a thorough inspection of hydraulic couplings for any early signs of wear or deformation. Maintenance routines should also incorporate alignment checks, stress tests, and proper lubrication schedules to ensure the optimal functioning of the hydraulic systems. Keeping detailed records of these maintenance activities helps in tracking the health of the system over time and can be crucial in identifying any patterns or recurring issues related to Brinelling.

By understanding and implementing these identification techniques and maintenance strategies, operators and technicians can effectively manage and mitigate the risks associated with Brinelling in hydraulic systems. This proactive approach not only ensures the longevity and reliability of the hydraulic systems but also maintains their efficiency and safety.

Preventing Brinelling in hydraulic couplings begins with a set of comprehensive best practices. Regular inspections are crucial, as early detection of wear can prevent more severe damage. Correct installation and alignment according to the manufacturer’s specifications are vital to avoid unnecessary stress on the couplings. Training for technicians on the proper handling and installation of hydraulic couplings can also play a significant role in preventing Brinelling.

Design plays a pivotal role in minimizing the risk of Brinelling. Opting for hydraulic couplings that feature designs aimed at distributing stress more evenly can significantly reduce the likelihood of surface indentations. For instance, couplings with larger contact surfaces can endure higher loads, reducing the risk of deformation. Additionally, incorporating flexible materials within the coupling design can mitigate the impacts of vibration and shock, common contributors to Brinelling.

The choice of materials and coatings is critical in combating Brinelling. Materials with higher hardness levels are generally more resistant to wear and less prone to Brinelling. However, it’s important to strike a balance, as materials that are too hard can become brittle and susceptible to other forms of damage. Protective coatings like chrome or nickel plating can add an extra layer of defense against wear and tear. It is also essential to consider the working environment of the hydraulic system; for example, corrosive environments may require special materials or coatings to ensure longevity and prevent Brinelling.

Quality control in the manufacturing process of hydraulic couplings is another key aspect. This includes precision in machining parts to ensure they fit together perfectly without undue stress or misalignment. High-quality manufacturing standards help in reducing the likelihood of defects that could predispose the couplings to Brinelling.

Customizing hydraulic couplings for specific applications can further reduce the risk of Brinelling. Understanding the specific needs and stressors of each application allows for the selection or design of couplings that are best suited to handle those conditions. This might involve custom materials, unique design modifications, or specific installation techniques.

By employing these best practices, thoughtful design considerations, careful material and coating selection, ensuring manufacturing quality, and customizing for specific applications, the risk of Brinelling in hydraulic couplings can be significantly minimized. This proactive approach not only extends the life of the couplings but also maintains the efficiency and safety of the entire hydraulic system.

The repair of Brinelled couplings begins with a meticulous inspection to evaluate the extent of the damage. If the Brinelling is minor, the first step is cleaning the area thoroughly to eliminate any contaminants. For mild indentations, use precision tools for smoothing the surface. In cases of significant Brinelling, you may need to machine the damaged part or replace it entirely. Post-repair, a comprehensive functional test is crucial. This test checks for any leaks and ensures that the coupling operates as expected under normal working conditions.

A robust maintenance plan is vital for extending the life of hydraulic couplings. Consistent inspections are key to early detection of wear. Regular lubrication according to the manufacturer’s specifications is essential to minimize friction and wear. Correct installation and alignment reduce stress on the couplings and prevent uneven wear. Monitor the system’s load to avoid overburdening the couplings. Following the operational guidelines strictly can significantly diminish the risk of Brinelling.

Deciding whether to repair or replace a Brinelled coupling involves considering several factors. For minor Brinelling, where the damage does not affect the structural integrity, repair can be an effective solution. However, in situations where the coupling has undergone multiple repairs or the Brinelling is extensive, replacing the part might be more cost-effective in the long term. When making this decision, consider the overall functionality and safety of the hydraulic system. Sometimes, choosing a more advanced or suitable coupling could be a strategic choice to prevent future Brinelling.

The environmental implications of hydraulic quick couplers extend beyond their manufacturing. These components, while small, play a significant role in larger industrial systems and their ecological footprint. The production process of these couplings often involves the use of metals and synthetic materials, which require energy-intensive manufacturing processes, contributing to carbon emissions and resource depletion.

Moreover, the use phase of these couplings is equally impactful. Hydraulic fluid leaks, though sometimes considered minor, can have detrimental effects on the environment. These leaks can contaminate soil and water sources, posing risks to wildlife and ecosystems. It underscores the need for robust designs that minimize leak potential and the importance of responsible disposal practices for both the couplings and the hydraulic fluids.These environmental challenges have led to an increased focus on sustainable practices in the industry.

Advancements in sustainable manufacturing for hydraulic couplings are notable. This includes the incorporation of recycled materials in the production process, the implementation of energy-efficient manufacturing techniques, and designing products for easier end-of-life recycling. These practices not only reduce waste but also conserve natural resources.

The emphasis on recycling and end-of-life management of hydraulic couplings represents a significant step towards sustainability in the industry. This involves using materials that can be easily processed at the end of the coupling’s lifecycle.

By designing for disassembly, manufacturers ensure that each component of the coupling can be separated and recycled effectively, thus minimizing waste.Furthermore, there is a growing trend towards using materials that are more environmentally friendly and easier to recycle. This shift is in response to the increasing awareness of the environmental impact of industrial waste. The recycling process itself is also being refined to be more energy-efficient and less polluting, contributing to a greener manufacturing cycle.These efforts towards recyclable and environmentally considerate hydraulic couplings are an integral part of fostering a circular economy within the industry.

The hydraulic industry is increasingly governed by stringent environmental regulations and standards. Compliance with these regulations involves limiting the environmental impact of manufacturing processes and promoting the development of environmentally friendly products. These standards are essential for reducing the ecological impact of hydraulic systems and aligning with global sustainability goals.

In this guide, we’ve covered the crucial aspects of Brinelling in hydraulic quick couplers. From understanding what Brinelling is, identifying its signs, to the importance of regular maintenance, we’ve delved into the complexities of this issue. The significance of addressing Brinelling cannot be overstated, as it directly impacts the efficiency and longevity of hydraulic systems. Continuous learning and adaptation in the face of evolving technology and environmental considerations are essential for anyone involved in the management or maintenance of these systems. Stay informed and proactive in your approach to ensure the optimal performance of hydraulic couplings.