Description

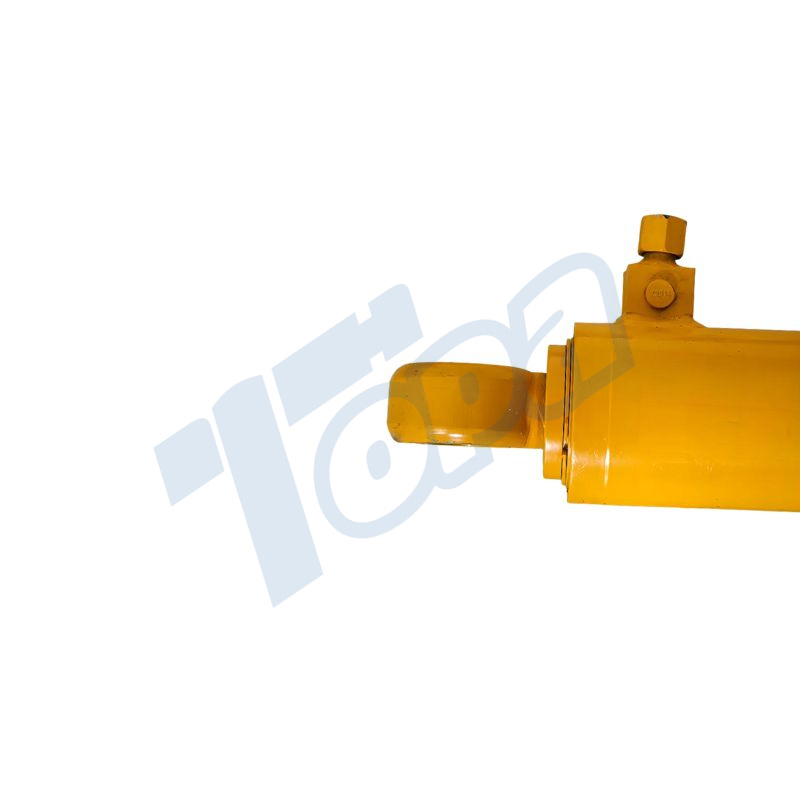

The Rotary Loader Bucket Cylinder is designed with a rugged, industrial look. They feature cylindrical steel bodies, polished chrome piston rods and complex head assemblies that allow for rotary motion. These cylinders typically have a unique appearance. This is because they come with additional rotating parts, which, depending on the design, may include external gears or rotating brackets. The exterior surfaces are often treated with a protective coating to withstand the wear and tear of the operating environment. The overall design is streamlined to facilitate smooth rotation and integration with the loader bucket mechanism.

The primary function of the rotary bucket hydraulic cylinder is not only to lift and tilt, but also to rotate. This additional function allows the bucket to be positioned more accurately for a variety of tasks such as leveling, grading and loading.

The size and stroke of these hydraulic cylinders are critical to their operation. However, we can customize them to meet the specific requirements of the loader.

Advantages

Versatility:

These cylinders enable the loader bucket to not only lift and tilt but also rotate, providing a greater range of motion and allowing for more complex movements and precision in operations.

Efficiency:

The ability to rotate the bucket without repositioning the entire loader can significantly speed up tasks and improve operational efficiency.

Durability:

Constructed with high-quality materials and designed to withstand the rigors of heavy-duty use, these cylinders are built for longevity and consistent performance.

Enhanced Control:

Operators have finer control over the placement and positioning of materials, which can improve safety and accuracy on the job site.

Space Optimization:

The rotational ability means that tasks can be completed in tighter spaces without the need to maneuver the entire machine.

Applications

Construction:

In construction, these cylinders are used for tasks that require precise movement of materials, such as grading, leveling, trenching, and backfilling.

Landscaping:

They allow for the detailed sculpting of land, such as creating slopes or swales, and are useful in planting or tree removal applications.

Agriculture:

These cylinders can be used in agricultural equipment for tasks like feeding livestock from a mixed feed pile or constructing and maintaining drainage systems.

Mining:

In mining, the ability to rotate the bucket allows for more precise excavation and material handling, improving the efficiency of loading and sorting processes.

Waste Management:

Rotating buckets are useful in waste sorting and recycling operations, allowing for the precise placement of materials into different processing areas or containers.

Rotating Loader Bucket Hydraulic Cylinder

The manufacturing process for Topa’s loading bucket hydraulic cylinders combines precision engineering and rugged construction. High-grade steel is used first, then the cylinders are machined to exacting tolerances and finally mated with pistons and rods to ensure strength and durability.

Integration of the rotary mechanism includes fine assembly to ensure smooth operation and reliability. Each cylinder undergoes a series of tests. Including pressure tests and rotary function checks, to ensure they meet the high standards required for heavy-duty applications.

Topa’s rotary loading bucket hydraulic cylinders bring a competitive advantage to heavy machinery, enhancing functionality through the ability to accurately perform complex loading and unloading tasks. The added rotary feature improves maneuverability and efficiency, reducing the time and space required for operation.

Topa offers a comprehensive customization service for rotary loader hydraulic cylinders to meet the specific needs of each customer’s machinery. Our service begins with a detailed assessment of the customer’s operational requirements, including load capacity, rotational range and environmental conditions. We then design hydraulic cylinders with precise dimensions, stroke lengths and mounting options to ensure a perfect fit.

Using state-of-the-art manufacturing processes, we can customize features. Such as variable mounting options, specialized seals for different temperature ranges, and unique port locations to fit existing hydraulic systems.

The key advantage of Topa’s customized hydraulic cylinders is the ability to provide solutions that are perfectly tailored to the customer’s equipment and operational needs. Our cylinders are manufactured using high quality materials and advanced sealing technology to ensure durability and reliability even under the most demanding conditions.

Customization also extends to the appearance of the cylinders, with a variety of coatings and finishes available to protect against corrosion and wear. Topa’s customized cylinders not only meet specific customer requirements, but also extend the life and productivity of heavy machinery investments.