Description

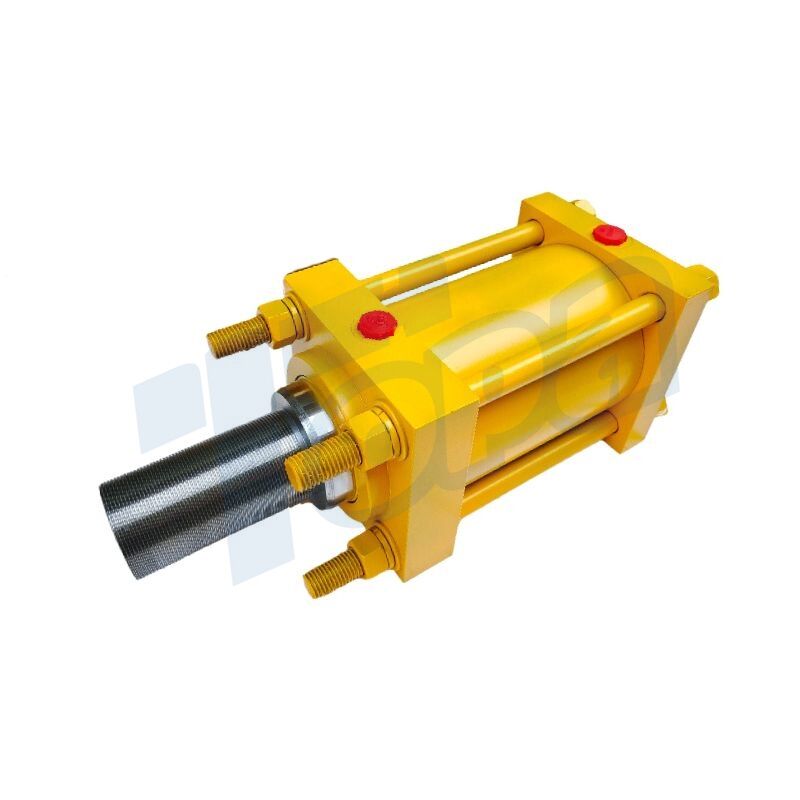

Double acting industrial tie rod hydraulic cylinders are engineered to provide versatile and robust solutions for a wide array of industrial applications. Unlike single-acting cylinders, these double-acting variants are capable of applying force in both extending and retracting directions, offering greater operational flexibility. The tie rods running along the length of the cylinder body serve as reinforcements, adding an extra layer of stability and durability to the overall structure.

In summary, tie rod industrial hydraulic cylinders offer a blend of versatility and durability that sets them apart. Their ability to exert force in both directions makes them suitable for complex operations, while the tie rod reinforcement ensures long-lasting performance. Whether you’re in manufacturing, construction, or any other industry requiring reliable hydraulic systems, these cylinders are a standout choice.

Structural Stability: The tie rod reinforcement ensures the cylinder remains stable under high-pressure conditions, enhancing durability.

Precision Control: The polished piston rod and quality seals allow for precise control of movement, essential for tasks requiring accuracy.

Bidirectional Operation: The double-acting design allows for force application in both extending and retracting directions, offering greater operational flexibility.

Longevity: The use of high-strength steel and quality seals ensures a longer operational life, reducing long-term costs.

Ease of Maintenance: The design allows for easy disassembly and reassembly, facilitating quick maintenance and repairs.

Automated Manufacturing: Ideal for use in automated systems where bidirectional force and precise control are required.

Heavy Machinery: Suitable for integration into heavy machinery like excavators, loaders, and cranes, where stability and durability are crucial.

Material Handling: Perfect for conveyor systems, lifting mechanisms, and other material handling equipment requiring bidirectional movement.

Agricultural Equipment: Useful in various agricultural machinery like tractors and harvesters for tasks such as lifting, pushing, or pulling.

Topa's Customized Services

At Topa, we understand that every client has unique requirements, and our customization services are designed to meet those specific needs.

Custom Sizing: Tailor the cylinder dimensions, including bore, stroke, and rod diameter, to fit specific applications and space requirements.

Material Selection: Choose from a variety of materials for the cylinder body and rod, such as stainless steel for corrosion resistance or coated rods for extra durability.

Pressure Specifications: Modify the cylinder to operate within specific pressure ranges, suitable for light-duty to heavy-duty industrial applications.

Mounting Options: Select from multiple mounting styles like flange, foot, clevis, or trunnion to ensure compatibility with existing machinery.

Seal Types: Opt for specialized seals that can handle extreme temperatures, chemical exposure, or higher pressures, depending on the operational environment.

Integrated Valves: Incorporate valves such as check valves, relief valves, or flow control valves directly into the cylinder for enhanced control and safety.

Color and Finishes: Specify colors and finishes for the cylinder to match branding requirements or to comply with industry standards.

Choose Topa for a truly personalized and reliable hydraulic solution.

Double Acting Tie Rod Industrial Hydraulic Cylinders

Topa is committed to producing the most sophisticated double acting tie rod type industrial hydraulic cylinders. The manufacturing process begins with the selection of quality materials to ensure that each component, from the high-strength steel cylinders to the durable piston rods, is built to withstand the rigors of industrial use. Then, state-of-the-art CNC machines accurately cut and shape each part to precise specifications to ensure a perfect fit.

Specialized technicians install the piston seals and attach the rods to the pistons to ensure smooth operation and a tight seal to prevent fluid leakage. The double-acting function of the cylinder is then tested, with rigorous evaluation of extension and retraction forces. This includes leakage tests at various pressures, as well as checking for any defects in movement or performance. Only after passing these stringent quality control measures are the cylinders considered ready for use.

Contact us today to place your order and make Topa your trusted partner.