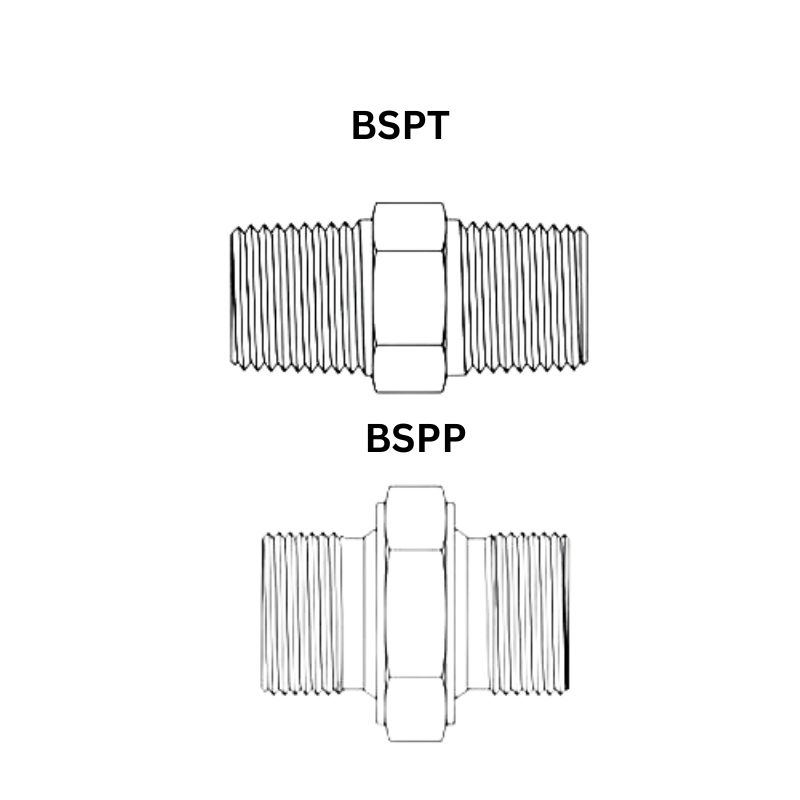

BSP threads, short for British Standard Pipe threads, are widely used worldwide in industrial and plumbing applications. Developed in the UK, they have become an international standard for threaded pipe connections due to their versatility and compatibility with various fittings. The two primary types of BSP threads are BSPT (BSP Tapered) and BSPP (BSP Parallel).

BSP Tapered vs Parallel: What’s the Difference?

Defining BSP Tapered Threads (BSPT)

BSPT (British StandardPipe Tapered) threads are designed with a taper, meaning the diameter of the threads gradually decreases from the base to the tip of the fitting. As the threads are tightened, the fitting becomes more compressed, which creates a self-sealing effect. This tapered design allows for a very tight and secure connection, making BSPT threads ideal for high-pressure applications.

Self-Sealing: The main characteristic of BSPT threads is their ability to self-seal as they are screwed into a matching female BSPT fitting. This is because the threads compress and create a seal as the parts are tightened.

Usage: BSPT threads are commonly used in hydraulic and pneumatic systems, gas lines, and other high-pressure applications where a leak-free connection is crucial.

Sealing Mechanism: Unlike parallel threads, BSPT threads do not require additional sealing materials like O-rings or sealants, as the taper naturally creates a tight fit.

Defining BSP Parallel Threads (BSPP)

BSPP (British Standard Pipe Parallel) threads are designed with a parallel structure, meaning the threads on the male and female fittings are the same size and run straight, with no taper. Because of this design, BSPP threads do not seal by themselves and require additional sealing methods, such as O-rings or thread sealants, to ensure a leak-proof connection.

Non-Self-Sealing: Unlike BSPT, BSPP threads do not form a seal on their own, so additional sealing mechanisms are necessary. This is often done by using thread sealants or gaskets to prevent leaks.

Usage: BSPP threads are often used in low-pressure systems or in situations where an external seal is preferred or needed. They are commonly found in applications where the user needs flexibility in sealing and disassembly, such as in fluid transfer systems and lower-pressure pipe connections.

Sealing Mechanism: BSPP threads often use additional components like O-rings, washers, or PTFE tape to create a secure, leak-resistant connection.

Key Differences Between BSPT and BSPP

Understanding the differences between BSPT and BSPP threads is essential when selecting the right thread for your application. Here’s a breakdown of the key distinctions:

Thread Design:

BSPT threads have a tapered design that naturally tightens and seals as the fitting is screwed into place.

BSPP threads have a parallel design, meaning the threads are the same size throughout the length, and they rely on external sealing materials.

Sealing:

BSPT threads self-seal due to their conical shape, making them ideal for high-pressure applications where a secure, leak-proof connection is needed without additional sealants.

BSPP threads do not self-seal and require the use of external sealing methods, such as thread sealants, PTFE tape, or O-rings.

Application Use:

BSPT is preferred in high-pressure applications like hydraulic, gas, and pneumatic systems, where the connection must be tight and leak-resistant.

BSPP is used in low-pressure or non-critical applications, such as in plumbing, water systems, or situations where you need flexibility with seals.

How BSP Tapered Threads Work

The Design of BSPT Threads

BSPT (British Standard Pipe Tapered) threads are specifically designed with a conical shape that gradually narrows as the threads extend from the base to the tip. This tapering allows the threads to tighten as they are screwed into a corresponding BSPT fitting, creating a self-sealing connection. Here’s how it works:

Tapered Thread Structure: The diameter of the male BSPT fitting starts larger at the base and decreases towards the tip, ensuring that as the fitting is tightened, the threads push against each other more tightly. This compression creates a seal between the male and female fittings.

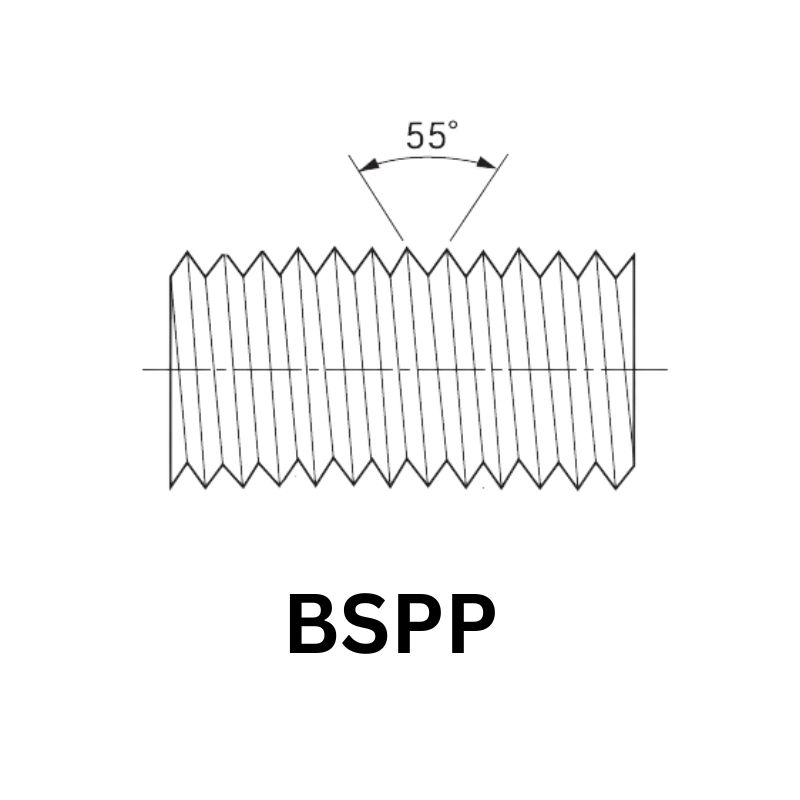

Thread Pitch and Angle: The pitch (distance between threads) and angle of BSPT threads are standardized to ensure uniformity and compatibility across different fittings and applications. The typical angle of the thread is around 55°, which ensures a solid seal and optimal pressure resistance.

Thread Fit: The male BSPT fitting is designed to fit snugly into the female BSPT fitting, with the taper providing the seal without the need for additional sealing materials, though thread sealant may still be used in some cases for added security.

Applications of BSPT Threads

BSPT threads are widely used across a variety of industries where secure, high-pressure connections are necessary. Their self-sealing nature makes them ideal for systems where leaks cannot be tolerated. Some common applications include:

Hydraulic Systems: In hydraulic systems, where fluids are pumped under high pressure, BSPT threads provide a reliable seal to ensure no fluid leakage, even under intense conditions.

Gas Line Connections: For natural gas or LPG systems, BSPT threads are used to prevent leaks and ensure the safety of the installation.

Oil and Gas Pipelines: The oil and gas industry relies on BSPT connections for piping systems that carry pressurized liquids or gases, where leaks would pose serious risks.

Industrial Equipment: BSPT threads are used in machinery and industrial equipment that requires tight, high-pressure connections to ensure the proper functioning of critical systems like cooling, lubrication, and fluid transfer.

BSPT in Real-World Examples:

Connecting high-pressure hoses to valves in industrial machines.

Creating leak-resistant joints in pressurized gas lines or water pipelines.

Ensuring secure connections in equipment like air compressors and pumps.

Advantages and Disadvantages of BSPT Threads

Like any other type of pipe thread, BSPT comes with both advantages and disadvantages depending on the application. Let’s break them down:

Advantages of BSPT Threads:

Self-Sealing: The key benefit of BSPT threads is their self-sealing nature. The tapered threads compress against each other as they are tightened, creating a tight, leak-resistant seal. This feature reduces the need for external sealing materials (e.g., thread sealants), making installation simpler and faster.

High-Pressure Resistance: BSPT threads are designed to withstand high-pressure conditions, making them ideal for applications like hydraulic systems, gas lines, and pneumatic systems where pressure control is critical.

Reliable and Secure Connections: The design of BSPT threads ensures a strong, durable connection that can handle vibrations and movement without compromising the seal, making them ideal for heavy-duty applications.

Minimal Risk of Leakage: Because the thread design inherently creates a seal, there is a minimal risk of leakage when BSPT fittings are properly installed and torqued.

How BSP Parallel Threads Work

The Design of BSPP Threads

BSPP (British Standard Pipe Parallel) threads are designed with straight, parallel threads that run the entire length of the fitting. Unlike BSPT (tapered) threads, BSPP threads do not naturally seal by themselves. Instead, the connection relies on additional sealing mechanisms, such as O-rings, gaskets, or thread sealants, to create a leak-proof joint. Here’s a breakdown of how BSPP threads function:

Parallel Thread Structure: BSPP threads are characterized by their straight threads that maintain a consistent diameter along their length. Both the male and female BSPP fittings have parallel threads that fit snugly together when tightened.

No Self-Sealing: Since BSPP threads are parallel, they do not self-seal like BSPT. The connection requires external sealing components to prevent leakage, typically applied to the male threads of the fitting.

Thread Pitch and Angle: The pitch of BSPP threads is standardized, and the angle of the threads is typically 55°, ensuring compatibility with a wide range of BSPP fittings. However, unlike BSPT threads, the angle and design of BSPP threads are optimized for the use of sealing compounds or gaskets rather than self-sealing through compression.

Applications of BSPP Threads

BSPP threads are commonly used in low-pressure or medium-pressure systems, where the need for a self-sealing thread is less critical. Since BSPP relies on additional sealing mechanisms, it is most suitable for situations where flexibility, reusability, and the ability to add or replace seals are important. Some common applications include:

Water Systems: BSPP threads are frequently used in water pipes and plumbing systems, where the pressure is lower, and the need for a self-sealing connection is reduced. The external seals, such as O-rings, can be easily replaced if needed.

Fluid and Gas Transfer Systems: In industries like oil and gas, chemicals, or fluid transfer, BSPP threads are often used because of their flexibility and the ability to use external sealing methods for leak prevention.

Air Compressors: BSPP threads are found in air compressor systems, where moderate pressure and the ability to replace seals as needed are required.

Industrial Equipment: BSPP is commonly used in low-pressure industrial applications, such as in machines, tools, and manufacturing equipment, where the sealing needs can be managed using gaskets or thread sealants.

Marine and Agricultural Systems: BSPP threads are often used in marine applications or agricultural equipment, where the threads need to be durable but also adaptable to changing conditions.

BSPP in Real-World Examples:

Connecting low-pressure water supply pipes in residential and commercial plumbing.

Fitting fluid transfer hoses to industrial machinery.

Using BSPP-threaded connectors in air supply systems for tools and machines.

Advantages and Disadvantages of BSPP Threads

BSPP threads come with both notable advantages and certain limitations. Understanding these pros and cons will help you decide when BSPP is the right choice for your application.

Advantages of BSPP Threads:

Flexibility with Seals: BSPP threads offer great flexibility when it comes to sealing methods. Since they do not rely on a self-sealing mechanism, you can use a variety of sealing materials, such as O-rings, PTFE tape, or liquid thread sealants, to achieve a secure, leak-proof connection. This allows customization depending on the specific needs of the system.

Reusability: The fact that BSPP threads do not self-seal means that the seals can be replaced when they wear out, making the connection more reusable. This is particularly useful in applications that require regular maintenance or disassembly.

Ease of Disassembly: Since BSPP does not form a permanent seal like BSPT, the connection can be easily disassembled and reassembled without damaging the threads. This makes BSPP ideal for applications where parts need to be frequently serviced or replaced.

Can BSPT and BSPP Be Used Together?

How BSPT and BSPP Fittings Interact

BSPT (Tapered) and BSPP (Parallel) threads, despite both being part of the British Standard Pipe family, are not inherently compatible with each other. They have fundamentally different thread designs, which can create issues if mixed. Here’s why:

BSPT Threads: BSPT threads are tapered, meaning that the male and female threads are conical in shape. As the fitting is screwed in, the threads compress against each other, creating a self-sealing effect. This compression tightens the seal and prevents leaks, which is why BSPT is commonly used in high-pressure systems.

BSPP Threads: BSPP threads, on the other hand, are parallel, with both male and female threads running at the same diameter along the length of the fitting. BSPP fittings require additional sealing materials like O-rings, PTFE tape, or thread sealants to prevent leaks, as the threads themselves do not form a tight seal.

When these two types of threads are mixed, several issues can arise:

Seal Failure: Since BSPT creates a self-sealing connection and BSPP requires external sealing, the two threads won’t form a reliable seal when paired together. This can result in leaks and potentially unsafe conditions in your system.

Misalignment: BSPT threads, because of their tapered nature, will not align correctly with BSPP fittings, which could lead to cross-threading or misalignment, causing difficulty in tightening the connection and risking thread damage.

Incompatibility with Pressure Systems: BSPT fittings are ideal for higher pressure systems due to their self-sealing properties, whereas BSPP fittings are better suited for low to medium pressure systems with external sealing. Mixing these thread types could lead to either over-pressurization or failure to maintain a secure connection under pressure.

Why Using the Wrong Thread Type Can Cause Issues

Using the wrong BSP thread type in your system can cause several serious problems:

Leaks: The most common and immediate issue when using incompatible thread types is leakage. BSPT threads form a tight, self-sealing connection as they taper, but BSPP threads depend on external sealing methods like O-rings or tape. If you attempt to connect BSPT and BSPP threads without the correct sealing method, the connection will fail, leading to leaks in the system. This is particularly dangerous in fluid or gas systems where leaks can cause system failure or environmental hazards.

Increased Wear and Tear: Improper connections can lead to increased stress on the fittings, causing them to wear out more quickly. For instance, if BSPT threads are forced into BSPP fittings, the taper may damage the parallel threads, resulting in a weakened connection and the need for more frequent maintenance or replacement.

Thread Damage: Trying to fit BSPT threads into BSPP fittings (or vice versa) could cause the threads to cross-thread, which will damage both the male and female threads. This makes the parts unusable and may require expensive replacements.

Unsafe Pressure: BSPT fittings are designed for higher-pressure applications, while BSPP is more suited for lower pressure systems. Using the wrong thread type can lead to unsafe pressure conditions. For example, using BSPP in a high-pressure system without proper sealing can lead to pressure leaks or blowouts.

Increased Maintenance Costs: If threads are mismatched, frequent maintenance or complete system overhauls might be needed. This increases downtime and operational costs, making it critical to use the correct BSP thread type from the outset.

How to Ensure Compatibility Between Threads and Fittings

To avoid the issues associated with using incompatible BSP threads, follow these steps to ensure compatibility between BSPT and BSPP fittings:

Know Your Thread Type: Always confirm whether you need BSPT or BSPP fittings for your specific application. Check manufacturer specifications for the thread type used in your system. BSPT will typically have a tapered appearance, whereas BSPP will have parallel threads.

Check the Pressure Rating: Match the pressure rating of the fittings with the correct thread type. BSPT is ideal for high-pressure systems, while BSPP is more commonly used in lower-pressure applications. Using the correct thread ensures the connection will hold under the operating conditions.

Use the Right Sealant: If you are using BSPP fittings, make sure to apply a suitable sealing material such as PTFE tape, liquid thread sealant, or gaskets. BSPT threads usually don’t require sealant, but they may still benefit from a little extra lubrication or PTFE tape to prevent galling.

Don’t Mix BSPT and BSPP: Avoid trying to connect BSPT and BSPP fittings together. These threads are designed differently, and mixing them will result in leaks, damaged threads, or failed connections. Always ensure that both the male and female threads are of the same type (BSPT or BSPP) to maintain a secure, leak-free connection.

Use Adaptors When Necessary: If you absolutely must connect BSPT to BSPP, you can use thread adapters that are specifically designed to make BSPT-to-BSPP conversions. These adapters will allow you to connect two different thread types without compromising the integrity of the connection.

Conclusion

Proper installation and regular maintenance are the keys to a safe, leak-free connection and long system life. If you have any needs or questions about BSP fittings, please feel free to contact us!

FAQ

What’s the difference between BSPT and BSPP threads?

BSPT (Tapered) threads have a conical shape that creates a self-sealing, leak-resistant connection. BSPP (Parallel) threads are straight and require external sealing methods, like PTFE tape or O-rings, to prevent leaks.

Can BSPT and BSPP fittings be used together?

No, BSPT and BSPP fittings are not compatible due to their different thread designs. Using them together can result in leaks or damage to the threads.

Which thread type is better for high-pressure systems?

BSPT threads are ideal for high-pressure applications because their tapered design ensures a secure, leak-resistant seal without additional sealing materials.

Do BSPP threads need sealing materials?

Yes, BSPP threads require external sealing materials such as PTFE tape, thread sealants, or O-rings to ensure a leak-proof connection.

How can I identify BSPT and BSPP threads?

BSPT threads are tapered and become narrower as they tighten, while BSPP threads are straight and parallel throughout.

Can I use BSPT with BSPP if I use a sealant?

Even with a sealant, BSPT and BSPP threads should not be mixed. They have different thread shapes, which may lead to poor sealing and possible damage to the fitting.