Hydraulic hose assemblies are essential components within machinery, serving as the lifelines that transmit hydraulic fluid between different parts of a hydraulic system. These assemblies are responsible for ensuring the efficient operation and precise power transmission required in various industrial applications. Their importance cannot be overstated, as they play a crucial role in maintaining the overall functionality and safety of hydraulic systems. A well-installed hydraulic hose assembly helps prevent fluid leaks, minimizes the risk of system failures, and contributes to the optimal performance and longevity of the machinery.

Key Components:

A hydraulic hose assembly is made up of several crucial components that work together to ensure the efficient and safe transmission of hydraulic fluid within a system. The primary components include:

Hoses: The flexible tubes that carry the hydraulic fluid between different parts of the system. Hoses are typically reinforced with multiple layers to withstand high pressures and are available in various materials to suit different applications.

Fittings: These are connectors at the ends of the hoses that allow them to be attached to other components within the hydraulic system, such as pumps, valves, and cylinders. Fittings are available in various styles and materials to match specific system requirements.

Adapters: Used to connect hoses and fittings that have different thread types or sizes, adapters ensure compatibility within the system.

Couplings: These are connectors that allow for the quick and easy connection or disconnection of hoses without the need for tools, making maintenance and repairs more straightforward.

Clamps: Essential for securing hoses in place, clamps prevent movement and vibration, which can lead to wear and potential failure over time.

Hydraulic hoses come in different types, each designed for specific applications based on factors such as pressure, flexibility, and durability:

Braided Hoses: Constructed with a braided reinforcement layer, these hoses are flexible and suitable for medium-pressure applications. They are commonly used in general hydraulic systems where flexibility is needed.

Spiral Hoses: Featuring multiple layers of spiral wire reinforcement, these hoses are designed for high-pressure applications and offer greater strength and durability compared to braided hoses. They are ideal for heavy-duty machinery and equipment.

Thermoplastic Hoses: Made from thermoplastic materials, these hoses are lightweight and resistant to various chemicals. They are used in applications requiring high flexibility and resistance to abrasion, such as in mobile equipment.

Factors to Consider:

Selecting the correct hydraulic hose is critical to the performance and safety of the hydraulic system. Several key factors must be considered:

Pressure Ratings: The hose must be able to withstand the maximum operating pressure of the system. Selecting a hose with an inadequate pressure rating can lead to failure and potential safety hazards.

Temperature Resistance: The hose should be capable of withstanding the temperature ranges of both the hydraulic fluid and the operating environment. High temperatures can degrade the hose material, leading to leaks or ruptures.

Fluid Compatibility: Not all hose materials are compatible with every type of hydraulic fluid. It’s essential to ensure that the hose material is chemically resistant to the fluid it will carry.

Environmental Conditions: The hose should be chosen based on the conditions it will be exposed to, such as UV exposure, abrasion, or chemical exposure. Selecting a hose that can withstand these conditions will extend its service life.

Reading Hose Specifications:

Understanding hose specifications is vital for selecting the right hose for your application. Hose specifications are typically marked on the hose itself and include important details such as:

Pressure Ratings: Indicates the maximum pressure the hose can safely handle.

Temperature Range: This shows the range of temperatures the hose can operate within.

Hose Size: Specifies the internal diameter of the hose, which affects the flow rate of the hydraulic fluid.

Material and Reinforcement: Identifies the materials used in the hose and its reinforcement layers, providing insight into its strength, flexibility, and durability.

Best Practices:

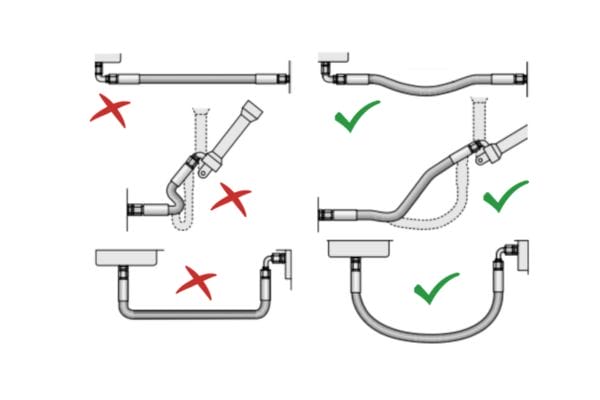

Proper hose routing is critical to preventing damage and ensuring the longevity of the hydraulic hose assembly. Follow these best practices to avoid common routing issues:

Avoid Sharp Bends: Hoses should not be routed in a way that forces them into sharp bends, as this can cause kinks, restrict fluid flow, and weaken the hose structure over time. Always follow the manufacturer’s recommended minimum bend radius.

Prevent Kinks: Ensure that the hose is not twisted or kinked during installation. Kinks can obstruct fluid flow and significantly reduce the hose’s lifespan.

Protect Against Abrasion: Route hoses away from sharp edges or abrasive surfaces that could wear away the outer cover. If contact is unavoidable, use protective sleeves or guards to shield the hose.

Proper Length and Clearance:

When routing hoses, it’s essential to ensure they have enough length and clearance to accommodate movement and system dynamics:

Adequate Length: Ensure the hose is long enough to accommodate the movement of the connected components without putting strain on the connections. A hose that is too short can be stretched, leading to premature failure.

Sufficient Clearance: Provide enough space around the hose for it to flex and move naturally with the machinery’s operation. Avoid routing hoses in tight spaces where they might rub against other components.

Attaching Fittings:

Attaching fittings correctly is crucial for a secure and leak-free connection. Here’s how to properly install different types of fittings:

Crimp Fittings: Use a crimping tool to securely attach the fitting to the hose end. Ensure the hose is cut cleanly and squarely before crimping to achieve a uniform seal.

Reusable Fittings: For reusable fittings, disassemble the fitting, insert the hose into the fitting body, and then reassemble by tightening the nut until it’s snug. Ensure the fitting is seated correctly to prevent leaks.

Push-On Fittings: Push the fitting onto the hose until it is fully seated. These fittings do not require clamps or crimping, but it’s crucial to ensure a tight fit to avoid leaks.

Correct Torque:

Using the correct torque when tightening fittings is essential to avoid damage and ensure a secure connection:

Torque Specifications: Always refer to the manufacturer’s torque specifications for the specific fitting type. Over-tightening can strip threads or crack fittings while under-tightening can lead to leaks.

Torque Methods: Use a calibrated torque wrench to achieve the correct torque. Apply torque gradually, ensuring the fitting is aligned properly and tightened evenly.

After cutting the pipe, you may notice rough edges or burrs at the cut ends. Use a deburring tool to remove these burrs, creating a smooth edge. This step is crucial as burrs can prevent the pipe from fitting properly into the fitting and can cause leaks. Once deburred, clean the pipe thoroughly to remove any debris, oils, or residues. Use a clean cloth or pipe cleaner to ensure the pipe is free of contaminants that could interfere with the seal.

Choosing the appropriate thread sealant is vital for a secure connection. Teflon tape, also known as PTFE tape, is widely used for most plumbing applications. Wrap the tape around the male threads of the fitting in a clockwise direction, covering the threads evenly without overlapping too much. For gas lines or applications requiring a more robust seal, pipe dope (thread-sealing compound) can be used. Apply the pipe dope to the male threads evenly, ensuring complete coverage. This sealant fills the gaps between the threads, preventing leaks.

System Connection:

Once the fittings are installed, the next step is to connect the hose assembly to the hydraulic system. Follow these steps:

Identifying Ports: Before connecting, identify the correct ports on the machinery for the hose assembly. Ensure that the ports are clean and free from debris.

Correct Connections: Align the hose assembly with the port and hand-tighten the connection to ensure it’s properly seated. Then, use a wrench to fully tighten the connection to the specified torque.

Sealants and O-Rings:

To prevent leaks at the connection points, it’s important to use the appropriate sealants and O-rings:

Thread Sealants: Apply a hydraulic-grade thread sealant to threaded connections. Avoid using excessive sealant, as it can migrate into the system and cause blockages.

O-Rings: Ensure O-rings are in good condition and properly seated in their grooves before tightening connections. Damaged or misaligned O-rings can lead to leaks.

Clamps and Supports:

Securing the hose assembly with clamps and supports is vital to prevent unwanted movement and vibration, which can lead to wear and failure:

Preventing Movement: Use clamps to hold the hose in place, preventing it from moving during machinery operation. This reduces the risk of abrasion and other damage.

Reducing Vibration: Supports and clamps should be positioned to minimize hose vibration, which can cause fatigue and early failure of the hose assembly.

Spacing Best Practices:

When installing clamps and supports, follow these spacing guidelines to ensure proper hose support:

Clamp Placement: Place clamps at regular intervals along the hose length, typically every 1.5 to 3 feet, depending on the hose diameter and application.

Avoiding Over-Tightening: Ensure that clamps are tight enough to hold the hose securely but not so tight that they crush or deform the hose. Clamps should provide firm support without restricting the horse’s ability to flex.

Proper Alignment:

After completing the installation, it’s essential to perform a thorough visual inspection to ensure that the hydraulic hose assembly is properly aligned. The hose should follow the intended routing path without any deviations, sharp bends, or contact with abrasive surfaces. Check that all fittings are securely fastened and positioned correctly, providing adequate clearance from other components and avoiding potential pinch points. Proper alignment reduces the risk of wear and tear, extending the life of the hose assembly and ensuring reliable system performance.

Stress-Free Assembly:

Inspect the hose assembly for any signs of twisting or undue stress. A twisted hose can lead to premature failure due to uneven stress distribution, while excessive strain on the hose can compromise its structural integrity. Ensure that the hose is free from kinks, tension, or compression and that it has enough flexibility to accommodate movement within the system. The assembly should be relaxed, allowing for natural expansion and contraction during operation without causing additional stress.

Testing Procedures:

Once the visual inspection is complete, the next step is to conduct a pressure test to verify the integrity of the hose assembly. Start by gradually increasing the system pressure to the recommended test pressure, which is usually higher than the operating pressure but within the hose’s specified limits. Monitor the assembly for any signs of leaks, bulges, or other failures. The pressure test should be conducted slowly and steadily, allowing time to identify potential weak points before they cause damage.

Safety Measures:

During pressure testing, it’s crucial to adhere to safety protocols to protect both personnel and equipment. Ensure that all personnel are at a safe distance from the hose assembly during testing and that appropriate protective gear is worn. Implement pressure release procedures to safely depressurize the system after testing. Never exceed the hose’s maximum pressure rating, and always follow the manufacturer’s guidelines for safe testing practices.

Post-Test Adjustments:

After completing the pressure test, make any necessary final adjustments to the hose assembly. Check clamps and supports to ensure they are positioned correctly and that the hose is securely fastened without restricting its natural movement. If any fittings or components need realignment or repositioning, do so carefully to maintain the integrity of the system. The goal is to optimize the hose assembly’s performance by fine-tuning its installation.

Rechecking Torque:

As a final step, recheck the torque values on all fittings and connections to confirm they are within the specified range. Over time, fittings may loosen slightly during testing or initial operation, so it’s important to ensure that each connection is tightened to the correct torque. Using a calibrated torque wrench, apply the appropriate torque to each fitting, making sure not to overtighten, which could damage the fittings or hose. Proper torque ensures a secure, leak-free connection that will withstand the demands of the hydraulic system.

Impact on Performance:

Using hoses that are either too short or too long can lead to significant performance issues within the hydraulic system. A hose that is too short may be stretched beyond its limits, leading to undue stress on the connections and potentially causing the hose to pull away from fittings or even rupture. Conversely, a hose that is too long can result in unnecessary slack, leading to kinks, loops, and increased wear due to friction and movement. Both scenarios can lead to reduced efficiency, increased risk of leaks, and premature failure of the hose assembly.

Selecting Correct Length:

To avoid issues related to incorrect hose length, it’s crucial to measure and choose the hose length carefully. Start by determining the required routing path and measure the distance while accounting for bends, twists, and potential movement of connected components. Add a small allowance to ensure the hose is not stretched but avoid excessive length that could lead to sagging. Using a hose that is cut to the exact required length ensures a secure fit and optimal performance without unnecessary stress on the system.

Risks:

Over-tightening fittings is a common mistake that can cause significant damage to both the fittings and the hydraulic system. Excessive torque can strip threads, crack fittings, or deform sealing surfaces, leading to leaks and compromised connections. Additionally, over-tightening can place undue stress on the hose and the system components, increasing the risk of failure under pressure. This mistake not only jeopardizes the integrity of the hose assembly but also increases maintenance costs and downtime.

Correct Torque Techniques:

To avoid the risks associated with over-tightening, always follow the manufacturer’s recommended torque specifications for each type of fitting. Use a calibrated torque wrench to apply the correct amount of torque, ensuring that the fitting is tightened just enough to create a secure, leak-free seal without damaging the components. It’s also important to apply torque gradually and evenly, checking the alignment and seating of the fitting throughout the process. Proper torque ensures a reliable connection that maintains system integrity.

Consequences:

Poor hose routing can have serious consequences for the hydraulic system, leading to accelerated wear, increased risk of leaks, and reduced system efficiency. Improper routing may cause hoses to rub against sharp edges, become kinked, or be subjected to excessive movement and vibration. These conditions can weaken the hose structure, leading to abrasion, leaks, or even sudden hose failure, which can cause costly damage to the machinery and pose safety hazards.

Routing Tips:

To optimize hose routing and avoid these issues, follow the best practices for routing hoses within the system:

Avoid Sharp Bends: Always adhere to the minimum bend radius specified by the hose manufacturer to prevent kinks and excessive stress on the hose.

Secure Proper Clearance: Ensure that hoses are routed with sufficient clearance from other components, avoiding contact with sharp edges or moving parts.

Use Clamps and Supports: Secure hoses with clamps and supports at regular intervals to prevent sagging and minimize vibration. Proper support helps maintain the hose’s position and reduces the risk of abrasion and wear.

Plan for Movement: If the hose is connected to moving parts, make sure the routing allows for natural movement without causing the hose to stretch, twist, or bend excessively.

In this guide, we’ve taken a comprehensive look at the hydraulic hose assembly installation process, covering everything from understanding the key components and selecting the right hose, to proper routing, fitting installation, and post-installation checks. We’ve highlighted common mistakes to avoid, such as incorrect hose length, over-tightening fittings, and improper hose routing, all of which can significantly impact system performance. By following these best practices, you can ensure a secure, efficient, and long-lasting installation that maintains the integrity of your hydraulic system.

The most important factors are pressure ratings, temperature resistance, fluid compatibility, and environmental conditions. These factors ensure that the hose will function safely and effectively in its intended application.

Measure the required length along the intended routing path, accounting for bends and movement. The hose should have enough length to avoid stretching but not so much that it sags or kinks.

Over-tightening can damage the fittings by stripping threads, cracking components, or deforming sealing surfaces, leading to leaks and compromised connections.

Regular maintenance should be performed based on the manufacturer’s recommendations, typically every few months, or whenever you notice signs of wear, leaks, or performance issues.

If a leak is detected during pressure testing, stop the test immediately, release the pressure safely, and inspect the hose assembly for loose fittings or damaged components. Address the issue before retesting.

Reusing fittings is generally not recommended, especially if they have been crimped or show signs of wear. Always inspect fittings for damage, and replace them if necessary to ensure a secure connection.