Tube fittings are an essential component in hydraulic and pneumatic systems, crucially ensuring the secure connection of tubes and pipes that transport fluids or gases under high pressure. These fittings are designed to prevent leaks, ensure reliable flow, and maintain the integrity of the system in various operational environments. This article will explore the different types of tube fitting connections, their strengths and weaknesses, and how they fare under specific conditions such as high pressure, extreme temperatures, and corrosive environments.

Types of Tube Fitting Connections

Flared Fittings

Definition and Mechanism of Flared Fittings:

Flared fittings are one of the most common types of tube connections used in hydraulic and pneumatic systems. In this type of fitting, the end of a tube is flared at a 37/45-degree angle to create a secure and leak-resistant connection when mated with a corresponding fitting. This flare provides an angled surface that enhances the sealing capability of the connection, ensuring the fitting can withstand high pressure and prevent leaks.

Typical Applications and Industries:

Flared fittings are commonly used in industries such as automotive, aerospace, refrigeration, and HVAC (Heating, Ventilation, and Air Conditioning). These fittings are often found in fuel lines, brake systems, and refrigeration units, where reliability and safety are of utmost importance. The automotive industry, for example, heavily relies on flared fittings in brake lines to ensure high-pressure fluid transfer without failure.

Pros and Cons of Flared Fittings:

Flared fittings are popular because they offer a strong and durable connection that can handle significant pressure. They are relatively easy to install with the proper equipment, and their flared design ensures a tight seal. However, the installation process does require precise flaring of the tube, which can be a disadvantage if not done correctly. Over-flaring or under-flaring can lead to poor seals and leaks. Additionally, flared fittings are best suited for soft materials like copper and aluminum, which may limit their use in some high-stress environments that require more robust materials.

Flareless Fittings

Overview of Flareless Fittings and How They Function:

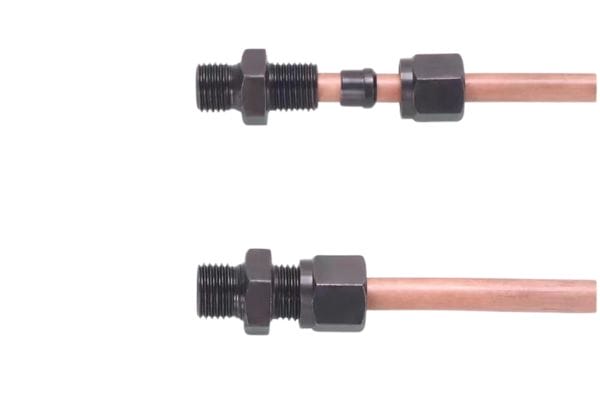

Flareless fittings, also known as compression fittings, do not require the tube to be flared. Instead, these fittings use a ferrule or compression ring that compresses around the tube when the fitting is tightened. This compression creates a seal between the tube and the fitting body, making it ideal for applications where flaring the tube is impractical or undesirable.

When Flareless Fittings Are Preferred:

Flareless fittings are typically preferred in applications where ease of installation and adaptability are priorities. They are commonly used in hydraulic systems, industrial machinery, and some plumbing systems. Their ease of assembly makes them popular in field repair situations where specialized flaring tools may not be available. In environments where vibration or thermal cycling is present, flareless fittings offer a more flexible connection that is less prone to loosening over time.

Advantages and Disadvantages:

One of the main advantages of flareless fittings is their ease of installation, which doesn’t require flaring tools or precise tube preparation. This makes them more versatile and less dependent on exacting installation conditions. Additionally, they provide a strong seal and are compatible with various materials, including harder metals like stainless steel. However, flareless fittings may not be as durable as flared fittings in extreme high-pressure environments, as the compression ring can wear down over time, potentially leading to leaks. They are also generally more expensive due to their complexity and materials.

Compression Fittings

Explanation of Compression Fitting Design:

Compression fittings are a type of flareless fitting but are worth discussing separately due to their widespread use and unique design. A compression fitting typically consists of three main components: a compression nut, a compression ring (ferrule), and a seat or body. When the nut is tightened, it compresses the ferrule onto the tube, creating a strong, leak-proof seal. The compression action also prevents the tube from moving, securing it in place.

How They Compare to Flared and Flareless Fittings:

Compared to flared fittings, compression fittings are easier to install since they don’t require any modifications to the tube itself, such as flaring. However, like flareless fittings, compression fittings rely on a ferrule that can wear over time, particularly in high-pressure or high-vibration environments. Compression fittings are often easier to use than flared fittings, making them preferable for installations in tight spaces or when working with harder materials that are difficult to flare.

Common Uses and Performance in High-Pressure Environments:

Compression fittings are frequently used in water supply lines, gas pipelines, and chemical processing plants. They are especially valued for their reliability in low to medium-pressure environments, though advanced versions can be designed for high-pressure applications. In hydraulic systems, compression fittings are often used where quick installation and maintenance are essential, such as in mobile equipment and heavy machinery. While they perform well under pressure, proper installation is critical to their success. Any misalignment during installation can reduce their effectiveness, causing leaks or fitting failure.

Factors That Influence Tube Fitting Performance

Operating Pressure and Temperature

How Different Pressures and Temperatures Impact Performance:

Tube fittings must maintain a secure, leak-free connection in environments that experience various pressure levels and temperatures. When pressure fluctuates or reaches extreme levels, the integrity of the fitting is tested. In high-pressure systems, such as those found in hydraulic applications, the fitting must be strong enough to withstand the force exerted on the connection points. Fittings that are not rated for these pressures can fail, leading to leaks or catastrophic system failures.

Similarly, temperature plays a critical role in performance. Extreme heat or cold can cause materials to expand or contract, potentially weakening the connection or causing seals to degrade over time. High temperatures may also accelerate the wear of softer materials, such as O-rings or gaskets, which can compromise the fitting’s sealing ability. On the other hand, low temperatures may make certain materials brittle and more prone to cracking under stress.

Material Compatibility Under Extreme Conditions:

Selecting materials that are compatible with the pressure and temperature requirements of the system is crucial. For example, stainless steel performs well under both high-pressure and high-temperature conditions, making it a popular choice for demanding applications. Brass fittings, while more cost-effective, may not be suitable for extreme temperatures and can weaken under high pressure. Additionally, plastic fittings may perform well in low-pressure systems but are generally not recommended for high-pressure or high-temperature applications. Ensuring that the fitting material matches the operational conditions is key to maintaining performance and avoiding premature failure.

Corrosion Resistance

Importance of Corrosion Resistance in Tube Fittings:

Corrosion resistance is a vital factor that directly influences the longevity and reliability of tube fittings. Corrosion occurs when a material reacts with its environment, often leading to rust, pitting, or other forms of deterioration that can weaken the fitting and compromise the seal. In hydraulic and pneumatic systems, even minor corrosion can lead to leaks, contamination of fluids, or complete system breakdown.

Corrosion is particularly problematic in environments where fittings are exposed to harsh chemicals, saltwater, or moisture. Industries such as marine, chemical processing, and food and beverage processing often require fittings with high corrosion resistance to prevent system failure and ensure safety.

Vibration and Shock Resistance

The Effects of Vibration on Fitting Reliability:

Vibration is a significant factor that can lead to loosening or wear of tube fittings over time. In industries where machinery or systems generate significant vibrations, such as in automotive, aerospace, or heavy equipment, fittings must be able to withstand these forces without compromising the connection. Constant vibrations can cause fittings to loosen, which may lead to leaks or even complete disconnection of the tubing. Shock, which refers to sudden, sharp movements or impacts, can also exert stress on fittings, making them prone to failure if not properly designed for such conditions.

Which Connections Perform Better in Environments with High Vibration:

Flareless and compression fittings generally perform better in high-vibration environments because they do not rely solely on mechanical tightening but also on the compression of ferrules or rings, which helps absorb vibration and maintain the integrity of the connection. Flared fittings, on the other hand, are more prone to loosening under vibration, especially if not adequately secured during installation. The use of vibration-resistant materials, such as flexible metals or elastomers, can also improve performance in these environments.

Rolled Versus Cut Threads

When it comes to threads in tube fittings, bolts, and other mechanical components, there are two primary methods for creating the threads: rolling and cutting. Each method has distinct characteristics, advantages, and best-use applications. Understanding the differences between rolled and cut threads can help in selecting the appropriate components for specific applications, especially in industries like hydraulics and pneumatics where thread integrity is crucial.

Cut Threads

Definition and Process:

Cut threads are created by physically cutting the threads into the material using a die or a lathe. During the cutting process, material is removed to form the desired thread shape. This method has been used for centuries and is still common in many applications today, especially when precision threading is required.

Key Characteristics:

Sharpness: Cut threads tend to have sharper and more defined edges due to the nature of the cutting process.

Precision: This method allows for highly precise threads, making it ideal for applications where the thread tolerance must be exact.

Stress Concentration: Because the material is removed during the process, cut threads can have a higher risk of stress concentration at the root of the thread, making them more prone to failure under high stress or fatigue.

Material Limitations: Cutting threads can be more difficult on hard materials like stainless steel or titanium, as the process requires strong cutting tools and can be time-consuming.

Applications:

Cut threads are typically used in applications where the highest level of precision is required, such as in custom fittings, aerospace components, and certain types of hydraulic systems.

Rolled Threads

Definition and Process:

Rolled threads are produced by deforming the material using dies. Instead of removing the material, rolling presses the material into the desired thread shape, using high pressure. The material is cold-worked, which enhances its strength and surface finish.

Key Characteristics:

Increased Strength: Rolled threads are generally stronger than cut threads because the rolling process cold-works the material, which increases its tensile strength and resistance to fatigue. The material at the thread root is compressed rather than removed, reducing the risk of stress concentration.

Improved Surface Finish: The rolling process results in smoother thread surfaces, which can enhance the fitting’s performance by reducing friction and wear during operation.

Higher Production Efficiency: Rolling threads is typically faster than cutting, making it more cost-effective for mass production.

Material Usage: Rolled threads result in no material waste, as no material is removed during the process, making it more efficient from a material standpoint.

Applications:

Rolled threads are commonly used in high-volume production environments and in applications where strength and durability are critical. Hydraulic fittings, automotive components, and fasteners in heavy machinery often feature rolled threads due to their enhanced strength and ability to handle high-pressure environments.

Comparison

Strength: Rolled threads generally offer greater strength and durability compared to cut threads due to the cold-working process. The grain structure of the material is also uninterrupted, which contributes to better fatigue resistance.

Precision: Cut threads provide higher precision and are more suitable for custom or highly specialized applications requiring exact tolerances.

Production Efficiency: Rolling is faster and more cost-effective for high-volume production, whereas cutting is better suited for low-volume or highly specialized threading needs.

Surface Finish: Rolled threads typically have a smoother finish, which can lead to better performance in dynamic applications such as hydraulic systems where smooth operation and resistance to wear are important.

Single versus Double Ferrule Fittings

Single Ferrule Fittings

Definition and Design:

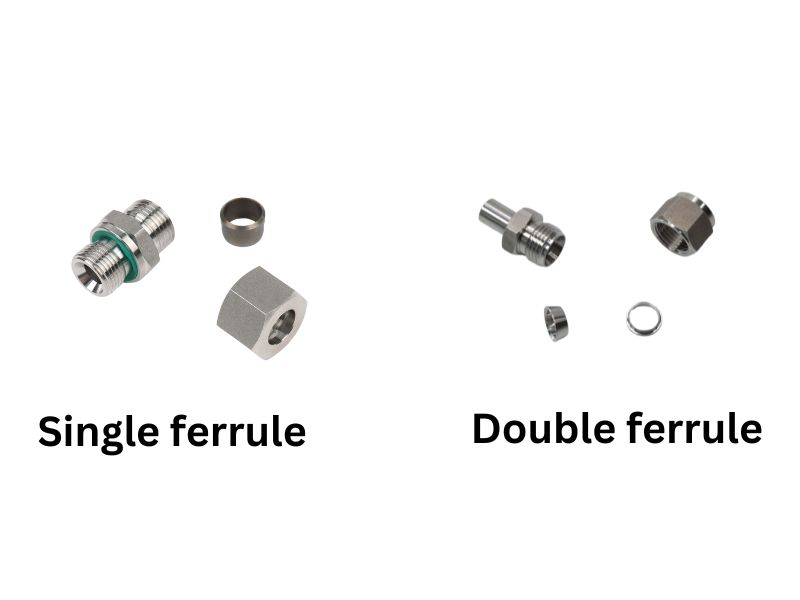

Single ferrule fittings utilize a single ferrule (a ring-like component) to compress and seal the tube within the fitting body. When the fitting is tightened, the single ferrule creates a grip on the tube, forming a tight seal to prevent leaks. The ferrule typically seats between the nut and the fitting body, and as the nut is tightened, the ferrule compresses around the tube.

Key Characteristics:

Simplified Design: With only one ferrule, the fitting design is straightforward, which can reduce the complexity of installation. This makes single ferrule fittings easier to work with in situations where simplicity and speed are desired.

Fewer Components: Fewer parts make these fittings lighter and generally more cost-effective compared to double ferrule systems.

Moderate Holding Power: Single ferrule fittings provide adequate grip and sealing for many low to medium-pressure applications. However, they may not offer as strong a grip as double ferrule fittings in high-pressure or high-vibration environments.

Double Ferrule Fittings

Definition and Design:

Double ferrule fittings use two separate ferrules to create a more secure connection. Typically, the front ferrule compresses onto the tube to form a tight seal, while the back ferrule grips the tube, ensuring that the connection remains secure and leak-free. The double ferrule system allows for more precise alignment and distribution of forces on the tube during tightening.

Key Characteristics:

Enhanced Grip and Seal: The double ferrule design provides greater holding power by distributing the gripping and sealing forces more evenly along the tube. This leads to a more reliable seal, particularly in high-pressure or high-vibration environments.

Vibration Resistance: Double ferrule fittings are highly resistant to loosening due to vibration, making them ideal for use in industries like aerospace, chemical processing, and oil and gas where systems are subjected to dynamic stresses.

Improved Tube Alignment: The dual ferrule system helps prevent tube misalignment during installation, which can be a critical factor in applications requiring precision.

Comparison of Single and Double Ferrule Fittings

Sealing and Holding Power: Double ferrule fittings generally provide superior sealing and holding power due to the dual-ferrule design. This makes them more suitable for high-pressure and high-vibration applications. Single ferrule fittings, while effective, are better suited for moderate conditions where extreme forces are not at play.

Vibration Resistance: Double ferrule fittings excel in environments with vibration or thermal expansion, ensuring the connection remains secure even under dynamic conditions. Single ferrule fittings may require additional maintenance or tightening in these environments.

Installation Complexity: Single ferrule fittings are simpler to install due to their single-component design, making them more appropriate for situations where ease of use is a priority. Double ferrule fittings, while more complex, offer a more reliable connection, though installation may take longer and require more precision.

Conclusion

Selecting the right tube fitting is not a one-size-fits-all decision; it requires a careful assessment of the system’s specific demands. The wrong choice can lead to leaks, system inefficiencies, or even failures, which can result in costly downtime, repairs, or safety hazards. By understanding the different types of tube fitting connections and their unique advantages, professionals can make informed decisions that improve system reliability and performance.

FAQ

What are tube fittings used for?

Tube fittings are used to securely connect tubes or pipes in hydraulic, pneumatic, or fluid systems, ensuring leak-free and reliable fluid transfer.

What is the difference between flared and flareless fittings?

Flared fittings require the tube to be flared at the end to create a seal, while flareless fittings use compression to seal the tube without needing a flare.

Why are double ferrule fittings preferred in high-pressure environments?

Double ferrule fittings provide a stronger mechanical grip on the tube, offering better leak resistance and durability under high pressure, vibration, and temperature fluctuations.

What are rolled threads, and why are they better?

Rolled threads are created by deforming the material rather than cutting it, resulting in stronger threads with better surface finish and accuracy, making them more durable.

How does corrosion resistance affect tube fitting performance?

Corrosion resistance ensures the longevity and reliability of tube fittings, especially in environments exposed to moisture, chemicals, or extreme conditions that could otherwise degrade the fittings.

When should I consider upgrading my tube fittings?

You should consider upgrading your tube fittings if you experience frequent leaks, pressure loss, or fitting failures, especially in demanding environments that require higher durability and reliability.