Hydraulic couplers are essential components in hydraulic systems, serving as the connection points that allow for the seamless transfer of hydraulic fluid between different parts of the machinery. In hydraulic systems, these couplers play a vital role by ensuring that the fluid power is transmitted effectively, minimizing leaks, and maintaining system pressure. Choosing the right hydraulic coupler is of utmost importance, as the wrong selection can lead to inefficiencies, increased wear and tear, and even system failures. This article will provide a comprehensive overview of the various types of hydraulic couplers, their specific applications, and key considerations for selecting the most suitable coupler for your needs.

Hydraulic couplers, also known as hydraulic quick couplings, are devices used to connect and disconnect hydraulic lines quickly and efficiently. Their basic function is to facilitate the smooth and swift connection of hydraulic hoses, pipes, or tubes without the need for tools, which is particularly beneficial in applications requiring frequent assembly and disassembly. Hydraulic couplers are designed to handle high-pressure fluid transfer, ensuring a secure and leak-free connection that maintains the integrity and performance of the hydraulic system. By enabling rapid connections, these couplers help minimize downtime during maintenance or equipment changes, enhancing overall operational efficiency.

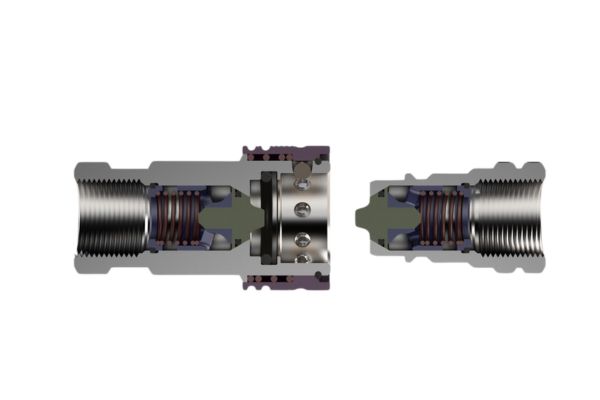

Hydraulic couplers are composed of several key components that work together to provide a secure and reliable connection. These components typically include:

Body: The main structure that houses the internal components and provides the connection interface.

Valve Mechanism: Often includes a poppet or ball valve that controls the flow of hydraulic fluid and prevents leaks when the coupler is disconnected.

Locking Mechanism: Ensures that the coupler remains securely connected under pressure. This can include various locking systems such as ball locking or thread locking.

Seals: Usually made of high-quality materials like rubber or synthetic compounds to prevent fluid leakage and ensure a tight seal.

Sleeve: The outer part that users manipulate to connect or disconnect the coupler. It often incorporates a push-pull mechanism for ease of use.

Each of these components plays a crucial role in the functionality and reliability of the hydraulic coupler, ensuring it can withstand the rigors of high-pressure applications while providing a safe and efficient connection.

Hydraulic couplers are utilized across a wide range of industries due to their versatility and reliability in managing fluid power connections. Some of the key industries and applications include:

Construction: Used in heavy machinery such as excavators, loaders, and cranes, where quick and secure connections are essential for hydraulic attachments and tools.

Agriculture: Employed tractors, combines, and other agricultural equipment to facilitate the attachment of implements and accessories that require hydraulic power.

Manufacturing: Integral in automated machinery and assembly lines, where hydraulic systems drive various mechanical processes.

Automotive: Applied in hydraulic systems for vehicle maintenance equipment, such as lifts and jacks, ensuring efficient and safe operation.

Mining: Essential for hydraulic-powered mining equipment, providing reliable connections in harsh and demanding environments.

Quick-release couplers are engineered for fast and effortless connection and disconnection of hydraulic lines without the necessity for tools. This feature is particularly valuable in environments where rapid setup and breakdown are frequent, thereby enhancing operational efficiency. These couplers typically comprise two primary components: a male and a female part, which engage with a straightforward push-pull action. The design commonly incorporates a locking mechanism, such as ball bearings or a sliding sleeve, to ensure a secure and reliable connection under pressure. This mechanism helps prevent accidental disconnections and ensures that the coupler maintains a tight seal even in demanding conditions.

Common Uses

Quick-release couplers are extensively utilized in scenarios where frequent connections and disconnections are required. They are particularly prevalent in:

Agricultural Machinery: For connecting implements and attachments like plows, seeders, and sprayers, ensuring that farmers can quickly switch between tools without significant downtime.

Construction Equipment: Found in excavators, loaders, and other heavy machinery, these couplers facilitate the attachment of hydraulic tools such as hammers, augers, and buckets, which are essential for various construction tasks.

Industrial Machinery: Used in maintenance and tool changes within factories and manufacturing settings, where speed and efficiency are crucial for maintaining productivity.

Flat-face couplers are specifically designed to minimize fluid loss and prevent contamination during connection and disconnection. They feature flat mating surfaces that seal directly against each other, eliminating cavities where hydraulic fluid can be trapped. This design also reduces air inclusion and spillage, making them ideal for maintaining the cleanliness of hydraulic systems. The flat-face design ensures that dirt and debris are less likely to enter the hydraulic system during connection and disconnection, thereby enhancing the overall reliability and longevity of the equipment.

Common Uses

Flat-face couplers are particularly suited for applications requiring high levels of cleanliness and minimal fluid loss. They are commonly used in:

Construction and Demolition Equipment: Where maintaining a clean hydraulic system is crucial for the performance and lifespan of heavy machinery.

Agricultural Machinery: Ensuring that hydraulic systems remain free from contaminants that can affect the performance and durability of farming equipment.

Industrial Hydraulic Systems: In environments where contamination control is critical, such as food processing and pharmaceutical manufacturing, where even small amounts of hydraulic fluid leakage can be problematic.

ISO-A couplers are standardized quick couplers that conform to the ISO 7241-1 Series A standard. They feature a poppet valve design that ensures reliable sealing and a robust connection. The standardized design means these couplers are interchangeable with other ISO-A couplers from different manufacturers, providing versatility and ease of use in various applications. The poppet valve mechanism helps maintain a secure seal and prevents fluid leakage, making them suitable for a wide range of hydraulic applications.

Common Uses

ISO-A couplers are commonly used in:

Agricultural and Forestry Equipment: For connecting hydraulic tools and attachments, ensuring seamless operation and efficiency in demanding outdoor environments.

Construction Machinery: Used in excavators, loaders, and other equipment to facilitate quick changes of hydraulic tools and accessories.

Industrial Hydraulic Systems: Providing reliable connections for maintenance and operation in manufacturing and processing plants.

ISO-B couplers conform to the ISO 7241-1 Series B standard and feature a ball-locking mechanism. This design ensures secure connections and disconnections, making them suitable for a variety of hydraulic applications. The ball-locking mechanism provides a reliable and strong connection, which is crucial for maintaining the integrity and performance of the hydraulic system.

Common Uses

ISO-B couplers are used in:

Hydraulic Systems for Agricultural Machinery: Ensuring reliable and quick connections for hydraulic tools and implements.

Construction Equipment: Providing secure connections for hydraulic attachments and tools in heavy-duty machinery.

Industrial Applications: Where robust and reliable connections are essential for maintaining operational efficiency.

Screw-to-connect couplers, as the name suggests, utilize a threaded connection that ensures a secure and leak-free joint, even under high-pressure conditions. These couplers consist of a male and a female component, which are screwed together to form an airtight seal. The design is highly robust, typically made from high-strength materials to withstand the mechanical stresses and vibrations encountered in demanding environments. The threaded interface provides an exceptionally strong connection that is less likely to disconnect accidentally, making it ideal for critical applications where reliability is paramount.

Common Uses

Screw-to-connect couplers are particularly suitable for:

High-Pressure Hydraulic Systems: Where the integrity of the connection is crucial for maintaining system performance and safety.

Applications Requiring Secure and Leak-Free Connections: Such as in high-stakes industrial operations where even minor leaks can lead to significant issues.

Environments with Heavy Vibration or Mechanical Stress: Including construction equipment, mining machinery, and other heavy-duty applications where equipment is subjected to constant movement and stress.

High-pressure couplers are engineered to handle extremely high hydraulic pressures, often exceeding those managed by standard couplers. They typically feature reinforced construction, utilizing high-strength materials such as hardened steel or advanced alloys. These couplers incorporate sophisticated sealing mechanisms, such as multiple O-rings or advanced valve designs, to ensure safe and reliable performance under extreme pressure conditions. The design also includes safety features to prevent accidental disconnection and to handle the intense forces encountered in high-pressure environments.

Common Uses

High-pressure couplers are essential in:

Heavy-duty industrial Machinery: Such as hydraulic presses, cranes, and other equipment operates under extremely high pressures.

Mining and Drilling Equipment: Where the equipment must withstand the harsh conditions and high pressures typical of these industries.

High Force and Pressure: Including aerospace testing, heavy lifting, and other critical operations that demand maximum reliability and safety.

Threaded couplers feature a threaded interface that provides a secure and leak-free connection, ideal for applications where a strong and reliable connection is essential. These couplers consist of a male and female component, each with threaded ends that screw together to form a tight, durable seal. The threaded design ensures that the connection can withstand varying pressures and mechanical stresses, making it suitable for a wide range of demanding applications. Threaded couplers are typically constructed from durable materials such as steel or brass, which provide longevity and reliability.

Common Uses

Threaded couplers are commonly used in:

Hydraulic Systems in Heavy Machinery: Ensuring secure connections in excavators, loaders, and other construction equipment.

Industrial Equipment with High-Pressure Requirements: Such as hydraulic presses, injection molding machines, and other industrial systems.

Applications Needing a Durable and Secure Connection: Including oil and gas exploration, manufacturing, and other heavy-duty industries.

Choosing the right quick coupling for your hydraulic system is crucial to ensure efficiency, reliability, and safety. Here’s a step-by-step guide to help you select the most suitable quick coupling for your needs:

Pressure Rating: Determine the maximum pressure your system will operate under and select a coupling that can handle this pressure without failing.

Temperature Range: Consider the operating temperature range. Ensure the coupling materials and seals can withstand these temperatures.

Fluid Compatibility: Check the hydraulic fluid used in your system and ensure the coupling materials are compatible with it to prevent corrosion or degradation.

Push-to-Connect: Ideal for applications requiring frequent connections and disconnections. They are easy to use and save time.

Screw-to-Connect: Suitable for high-pressure applications where a secure and leak-free connection is critical. They are more robust and reliable under heavy loads and vibrations.

Flow Rate Requirements: Calculate the required flow rate for your system and choose a coupling with the appropriate size to handle the flow without causing pressure drops or inefficiencies.

Connection Size: Ensure the coupling size matches the size of the hoses or pipes in your system to maintain proper fitting and prevent leaks.

Exposure to Contaminants: If the coupling will be used in environments with dirt, dust, or other contaminants, consider flat-face couplings that minimize fluid loss and contamination during connection and disconnection.

Corrosive Environments: Choose couplings made from materials resistant to corrosion, such as stainless steel, if they will be exposed to harsh chemicals or saltwater.

Connection and Disconnection Frequency: For applications requiring frequent changes, quick-release couplings are ideal due to their ease of use.

Maintenance Requirements: Consider the maintenance needs of the coupling. Some designs may require regular inspections and replacements of seals to ensure continued performance.

ISO and SAE Standards: Look for couplings that conform to industry standards such as ISO 7241-1 Series A or B, ensuring compatibility and interchangeability with other couplings from different manufacturers.

Brand Compatibility: If you use couplings from multiple brands, ensure they are interchangeable to simplify inventory management and replacement.

Choosing the most suitable quick coupling involves careful consideration of your system’s requirements, environmental conditions, ease of use, and long-term value. By following these steps, you can ensure that you select a coupling that enhances the performance, reliability, and safety of your hydraulic system.

Throughout this article, we have explored the various types of hydraulic couplers. Choosing the right hydraulic coupler is essential for maintaining the efficiency, reliability, and safety of your hydraulic system. Understanding the strengths and limitations of each type of coupler will help you make an informed decision that can enhance the performance of your equipment and reduce downtime.

A hydraulic coupler is a device used to connect and disconnect hydraulic lines quickly and securely, allowing for the transfer of hydraulic fluid between components in a hydraulic system.

Consider factors such as pressure rating, temperature range, fluid compatibility, environmental conditions, ease of use, and maintenance requirements. Match these factors to your specific application needs.

The main types of hydraulic couplers include quick-release couplers, flat-face couplers, ISO-A couplers, ISO-B couplers, screw-to-connect couplers, high-pressure couplers, and threaded couplers.

Many hydraulic couplers conform to industry standards such as ISO or SAE, making them interchangeable between brands. However, always verify compatibility to ensure a secure and leak-free connection.

Regular maintenance, including inspections for wear and tear, is crucial. Replace hydraulic couplers based on the manufacturer’s recommendations or if you notice signs of damage, leaks, or reduced performance.

Quick-release couplers allow for fast and easy connection and disconnection without tools, minimizing downtime during maintenance or equipment changes and reducing the risk of fluid leaks during disconnection.

Have a question or suggestion? Fill out the form below to get in touch with one of our experts.