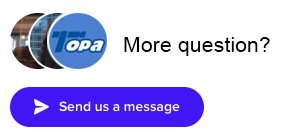

What is ORS Hydraulic Fitting: A Comprehensive Guide

Table of Contents

Introduction

Hydraulic fittings are the centerpiece of a hydraulic system, and among them, ORS fittings also play an important role. ORS refers to fittings that contain an o-ring that is secured in a groove and pressed to form a tight seal during assembly. We will discuss their design, function and role in hydraulic systems. In addition, we’ll discuss how to select the right ORS fitting for your needs and highlight factors to consider to ensure optimal performance and service life.

The Basics of ORS Hydraulic Fittings

Definition and Functionality

An ORS (O-Ring Seal) hydraulic fitting is a component used in hydraulic systems to ensure a tight and secure connection between different parts of the system. These fittings play a critical role in maintaining the integrity of the hydraulic system by preventing leaks, which could lead to system failure or decreased efficiency. The effectiveness of ORS hydraulic fittings lies in their ability to create a robust seal, crucial for systems handling high pressures and varying temperatures.

Design Features

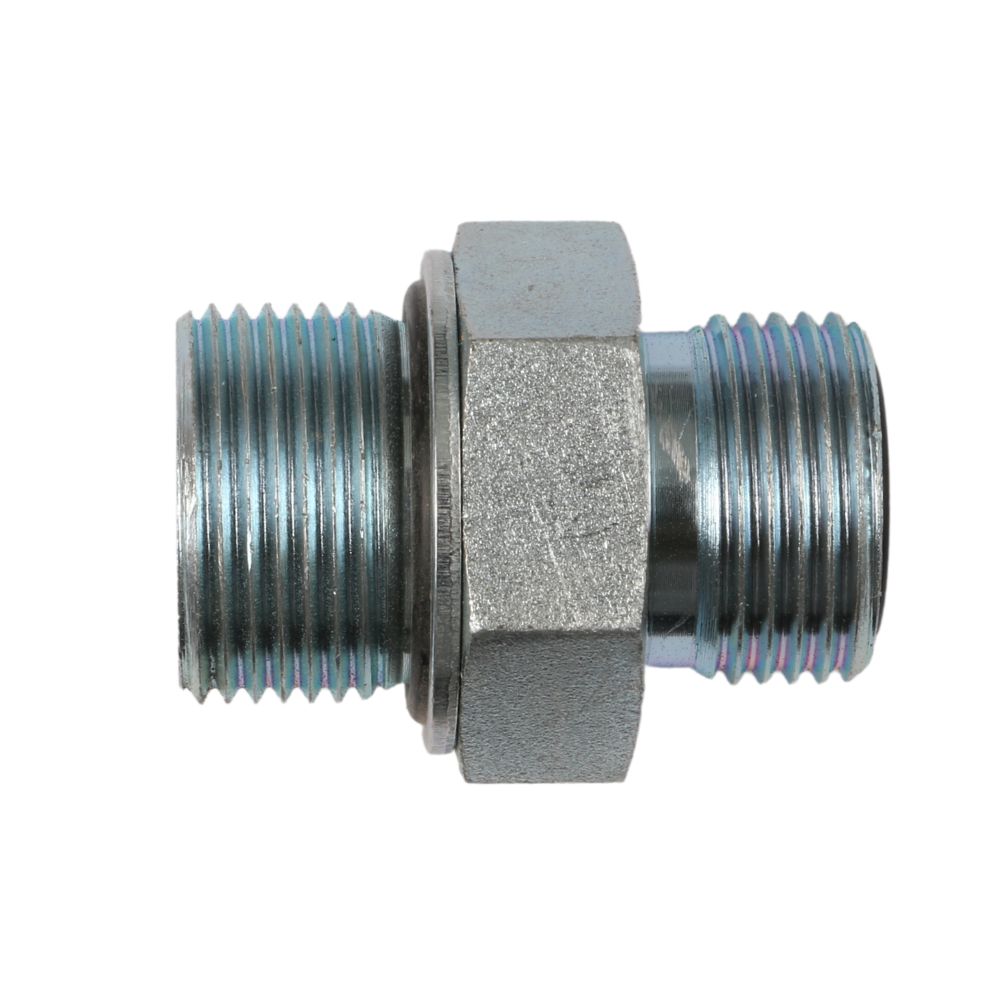

The hallmark of ORS hydraulic fittings is the incorporation of an O-ring seal along with metal-to-metal contact. The O-ring, usually made of rubber or a similar flexible material, is seated in a specifically designed groove. When the fitting is assembled, the O-ring gets compressed, forming a tight seal that prevents fluid from leaking. The metal-to-metal contact further enhances this sealing capability, ensuring a reliable connection even under high pressure. This combination of features is vital in hydraulic systems where even a minor leak can lead to significant issues.

Types of ORS Fittings

ORS hydraulic fittings come in various types, each designed for specific applications and requirements. Some common types include adjustable, crimp, and swivel fittings, among others. Adjustable fittings allow for ease of installation and alignment, while crimp fittings are known for their robustness and are often used in high-pressure applications. Swivel fittings provide flexibility, enabling movement without compromising the integrity of the connection. Understanding these types and their unique features is key to selecting the right fitting for a specific application.

Compatibility and Uses

ORS fittings are versatile and compatible with a wide range of hydraulic hoses and tubes. This compatibility is crucial in diverse applications, from industrial machinery to automotive systems. For instance, in construction equipment, ORS fittings might be used for their ability to withstand vibrations and shocks, while in automotive applications, their compact size and leak-proof nature are more valued. The choice of an ORS fitting depends on several factors, including the type of fluid being transported, the operating pressure, and environmental conditions.

Types and Variations of ORS Fittings

ORS hydraulic fittings are integral components in various hydraulic systems, and understanding their types and variations is crucial for selecting the appropriate fitting for specific applications.

The different types of ORS fittings include:

1. Standard ORS Fittings: These are the most common types used in general hydraulic applications. They are known for their robust construction and effectiveness in preventing leaks.

2. Adjustable ORS Fittings: These fittings offer flexibility in installation, allowing for adjustments to be made for proper alignment and sealing.

3. Swivel ORS Fittings: Designed to provide rotational movement, these fittings are ideal in applications where hoses and tubes need to move without twisting or kinking.

4. Bulkhead ORS Fittings: Used in applications where hoses or tubes need to pass through a panel or bulkhead, maintaining a leak-proof seal.

5. Elbow and Tee ORS Fittings: These fittings are used to change the direction of the hydraulic lines or to branch out connections, respectively.

Identifying ORS fittings typically involves examining the characteristics of the O-ring seal and the threading. ORS fittings have a flat face for the O-ring to seat and a threaded section for connection. The presence of a visible O-ring is a distinctive feature in identifying these fittings.

In comparison to other hydraulic fitting types, such as JIC (Joint Industry Council) and NPT (National Pipe Thread), ORS fittings have some distinct differences. JIC fittings are known for their 37-degree flare seating surface, which differs from the flat face of ORS fittings. NPT fittings, on the other hand, have tapered threads and do not use an O-ring for sealing, unlike the ORS fittings. These differences are important in determining the right fitting type for specific pressure ratings and applications.

Understanding the types, identification methods, and comparative features of ORS hydraulic fittings aids in making informed decisions in hydraulic system design and maintenance.

Advantages of Using ORS Hydraulic Fittings

ORS hydraulic fittings, known for their robustness and efficiency, offer several advantages making them a preferred choice in various hydraulic applications.

Leak Prevention

One of the primary benefits of ORS fittings is their exceptional ability to prevent leaks. The O-Ring seal in these fittings provides a tight and secure connection, ensuring that hydraulic fluid is contained within the system. This is especially critical in systems where even a small leak can lead to significant operational issues or safety hazards.

Pressure Resistance

ORS fittings are designed to withstand high-pressure conditions, making them suitable for use in heavy-duty hydraulic systems. Their robust construction ensures that they can handle the stress and strain of high-pressure applications without failing, ensuring the reliability and longevity of the hydraulic system.

Durability

Constructed with high-quality materials, ORS fittings are built to last. They are resistant to wear and tear, which is essential in systems that are in constant use or exposed to harsh environments. Their durability translates into less frequent replacements, reducing downtime and maintenance costs.

Advantageous in Specific Scenarios

In scenarios such as mobile hydraulics, agricultural machinery, and industrial applications, the advantages of ORS fittings are particularly evident. Their ability to maintain a leak-proof seal in dynamic and vibrating environments makes them indispensable in these sectors. In mobile hydraulics, for instance, the constant movement and vibration could compromise the integrity of a hydraulic system, but ORS fittings maintain a secure connection, ensuring the smooth operation of the machinery.

Technical Specifications of ORS Fittings

The technical specifications of ORS (O-Ring Seal) hydraulic fittings are crucial for ensuring proper functionality and compatibility within hydraulic systems.

Sizes, Pressure Ratings, Materials

ORS fittings come in a range of sizes to accommodate various hydraulic hose and tubing diameters. The size of the fitting is typically correlated with the inner diameter of the hose or tube it is meant to connect. Pressure ratings for ORS fittings vary, with some designed to handle extremely high pressures, making them suitable for industrial and heavy machinery applications. The materials used in ORS fittings include steel, stainless steel, and brass, each chosen for its durability and resistance to corrosion and wear. The selection of material depends on the specific application, considering factors like the type of hydraulic fluid, environmental conditions, and pressure requirements.

Understanding Standards

ORS fittings are governed by specific standards, including SAE J1453 and various ISO standards. These standards outline the dimensions, tolerances, and performance requirements for ORS fittings. SAE J1453, for instance, specifies the dimensions for O-ring face seal fittings used in hydraulic tubing. Adhering to these standards is crucial for ensuring the fittings’ compatibility and performance in hydraulic systems.

Specification Sheets

Reading and understanding specification sheets is essential for selecting the right ORS fitting. These sheets provide detailed information about the fittings, including their size, material, pressure rating, and compliance with relevant standards. The specification sheet will also often include information about the O-ring material and its compatibility with different hydraulic fluids. Understanding how to interpret these sheets helps in making informed decisions when selecting fittings for a hydraulic system.

Installation Guide for ORS Hydraulic Fittings

Step-by-Step Instructions for Fitting Installation

Installing ORS hydraulic fittings correctly is crucial for the efficiency and safety of hydraulic systems. Here’s a step-by-step guide, common mistakes to avoid, and tips for a secure installation:

Step-by-Step Installation Guide

- Preparation: Before starting, ensure that all components are clean and free from debris. Check the fitting and tubing for any damage.

- Inspect the O-Ring: Make sure the O-ring is in good condition and properly seated in its groove on the fitting.

- Lubrication: Lightly lubricate the O-ring with a fluid compatible with the system to facilitate a smooth installation.

- Aligning the Fitting: Carefully align the ORS fitting with the tube or hose. Misalignment can cause the O-ring to pinch or tear.

- Hand Tightening: Initially, tighten the fitting by hand to ensure that the threads are correctly engaged.

- Final Tightening: Use appropriate tools to tighten the fitting to the manufacturer’s specified torque. Over-tightening can damage the O-ring, while under-tightening might lead to leaks.

Common Installation Mistakes

Overlooking O-Ring Inspection: Not inspecting the O-ring for damage or proper placement is a common oversight.

Cross-threading: Starting the fitting at an incorrect angle can lead to cross-threading, damaging both the fitting and the receiving port.

Incorrect Torque: Applying too much or too little torque can compromise the fitting’s integrity.

Tips for Secure and Leak-Free Installation

Follow Manufacturer Guidelines: Always adhere to the manufacturer’s installation instructions, especially regarding torque specifications.

Use Proper Tools: Employ the correct tools for installation to avoid damaging the fitting.

Regular Inspection: After installation, periodically inspect the fitting to ensure it remains secure and leak-free.

Correctly installing ORS hydraulic fittings ensures the longevity and reliability of hydraulic systems. Proper installation reduces the risk of leaks and potential system failures, contributing to overall operational efficiency.

Maintenance and Troubleshooting

Maintaining and troubleshooting ORS (O-Ring Seal) hydraulic fittings are essential to ensure the longevity and efficient performance of hydraulic systems.

Routine Maintenance Tips

- Regular Inspection: Periodically inspect ORS fittings for signs of wear, corrosion, or damage. Pay special attention to the condition of the O-ring.

- Cleanliness: Keep the fittings clean. Accumulated dirt and debris can compromise the integrity of the hydraulic system.

- Check for Leaks: Regularly check for leaks around the fittings. Even small leaks can lead to significant issues over time.

- Lubrication: Ensure that the O-rings are properly lubricated with a fluid that is compatible with the hydraulic system. This helps in maintaining a good seal and prolongs the life of the O-ring.

- Tightening Check: Periodically check and retighten the fittings as needed, adhering to the manufacturer’s torque specifications.

Troubleshooting Common Issues

- Leaks: If a leak is detected, first try tightening the fitting to the recommended torque. If the leak persists, inspect the O-ring for damage and replace it if necessary.

- Decreased Performance: If there is a noticeable decrease in system performance, check for any obstructions or damages to the fittings that might be causing flow restrictions.

- Unusual Noises: Sounds like whining or banging may indicate problems in the fitting connections. Inspect for loose fittings or air in the system.

When to Replace and Upgrade Your Fittings

- Wear and Tear: Over time, fittings can wear out, especially in high-pressure environments. Replace fittings that show signs of significant wear.

- System Upgrade: If the hydraulic system is being upgraded or modified, it may be necessary to replace ORS fittings to ensure they are compatible with the new system requirements.

- Damage: Any visible damage, such as cracks or thread stripping, is a clear indication that the fitting should be replaced.

Maintaining and troubleshooting ORS hydraulic fittings are key practices that contribute to the efficiency and safety of the entire hydraulic system. Regular maintenance, coupled with timely troubleshooting and replacement, helps in avoiding system failures and prolongs the lifespan of the hydraulic components.

Purchasing Guide for ORS Hydraulic Fittings

When purchasing ORS hydraulic fittings, several factors should be considered to ensure you select the right components for your hydraulic system.

Quality Considerations

The quality of ORS fittings is paramount. When selecting these fittings, consider the material composition – stainless steel, brass, or carbon steel – each offering different levels of strength and corrosion resistance. Also, look at the manufacturing standards; fittings that meet or exceed industry standards like SAE J1453 or ISO standards are generally more reliable. Durability is another key factor; choose fittings that are known for their long-lasting performance, especially in challenging environments.

Size and Specifications

Choosing the right size and specification is crucial. The fitting must match the size of the hose or tube it is intended to connect. A mismatch can lead to leaks or system failures. Consider the inner and outer diameters of the hose or tube and the fitting’s thread size and type. The specifications should also align with the system’s pressure requirements and the type of fluid being transported.

Manufacturer Reputation

Opt for fittings from reputable manufacturers. Well-known brands are often synonymous with quality and reliability. Look for manufacturers who offer fittings that comply with international quality standards. Industry certifications or standards are good indicators of a manufacturer’s commitment to quality.

Assessing Needs

Before purchasing, assess the specific needs of your hydraulic system. Consider the operating pressure, the type of hydraulic fluid used, and environmental conditions like temperature and potential exposure to corrosive substances. Compatibility with existing system components is also critical to ensure seamless integration and operation.

By considering these factors, you can make an informed decision when purchasing ORS hydraulic fittings, ensuring the efficiency and reliability of your hydraulic system.

Conclusion

We delve into the basics of ORS fittings, outlining their design, function and different types. We also highlight their benefits. Understanding technical specifications, proper installation procedures, routine maintenance and troubleshooting are key to the optimal use of ORS fittings. Proper selection, installation and maintenance of hydraulic fittings can have a significant impact on the performance of these systems. We encourage readers to continue to explore and learn about hydraulic systems, and with a better understanding of components such as ORS fittings, you will be better able to ensure the smooth operation and longevity of your hydraulic system.