Compatible Hose Clamps Manufacturer in China

The hose clamp is a device that clamps onto the hose and is used to secure the hose to prevent leakage of fluid within the hose.Hose clamps are very versatile and they can usually be used in medium or low pressure environments. The most common materials used for hose clamps are stainless steel and carbon steel. Other materials, such as titanium, plastic, and galvanized steel are also suitable for hose clamps.

Product List

Topa can offer differrent types of hose clamps, the common types are as follows: ear clamps, spring type hose clamps, worm type hose clamps, single and double line clamps, quick release clamps, hole clamps with inclined housing, spiral clamps, etc.

Band hose clamp

Pre-formed band hose clamps secure couplings and fittings to hoses fast.

Rectangular hose clamp

Rectangular hose clamps are usually made of stainless steel.This clamp is connected and installed on square tube.

Bridge hose clamp

With a special bridge geometry, Bridge hose clamps can be fitted on spiral hoses easily and quickly.

Germany type hose clamp

Germany type hose clamp's band is non-perforated,protecting the hoses surface from shearing during installation

Hose clip

Durable and rust-frere hose clip, with different types and materials.

Hose clamp spring

Hose clamp spring is a special spring that is used in hose clampe.

Garden hose clamp

The garden hose clamp is available in a large number of materials, and it is used to connect garden hoses.

Garden hose clip

The garden hose clip is available in a huge number of materials, and it is used to connect garden hoses.

Radiator hose clamps

High-quality hose clamps, are used for radiator. High-temperature resistance.

Adjustable hose clamp

Adjustable hose clamps allow the size and position of the hose clamps to be adjusted to suit individual needs.

Worm gear hose clamp

Worm gear hose clamps are a type of metal band clamp. They have a spiral shaped thread. They provide a high torque clamp.

Quick release hose clamp

The quick release pipe clamp allows a secure and fast tighten for hose and pipes.

Stainless steel hose clamp

Made of high-quality stainless steel, long-lasting and rust-free.

Titanium hose clamp

Titanium hose clamps are made of pure titanium alloy, which is corrosion-resistant and rust-resistant.

Aluminum hose clamp

Aluminum hose clamps are made of high quality aluminum and can be used in a number of applications.

Rubber coated clamp

Rubber coated hose clamps are a layer of rubber wrapped around the surface of a metal clamp to provide a more secure connection.

Single ear hose clamp

The single ear hose clamp is typically made of stainless steel, rust-free and corrosion-resistance.

Single wire hose clamp

Single wire clamps provide effective clamping force and strength. The single wire concentrates the clamping force on a specific area of the hose.

Double ear hose clamp

Double-ear hose clamps ensure a tight connection to the hose. Reliable and durable.

Double wire hose clamp

The double wie hose clamp is a prefect choice for rubber and PVC hoses. Durable and easy to operate.

American hose clamps

American hose clamps are the standard hose clamps in the United States and can be used in trains, ships, automobiles and other applications.

British type hose clamps

British style hose clamps are made according to British standards. Reliable and corrosive.

German type hose clamps

German type hose clamps are designed and manufactured according to German specifications.

Heavy duty hose clamps

Topa hose clamp heavy duty is a type of clamp that is used for tightening heavy-gauge reinforced hoses.

T bolt hose clamps

The T bolt hose clamp provides perfect strength and a whole leak-proof seal.

Type P hose clamps

The P-type hose clamp is used to bracket wires, cables or hoses together. It has the rubber coated in its flare.

Band hose clamps

The band hose clamps are used to secure the pipes, hoses and adapter.

Hose clamp strap

Hose clamp strap is adjustable clamping band, there are stainless steel, carbon steel and other materials.

Brake line hose clamps

Brake line hose clamps can be used securely with brake lines, strenght and duable.

Hose clamps video

The video below is a detailed description of the hose clamps, please click on the video to watch.

Topa manufacturer hydraulic fittings

We are hose clamps manufacturer, we provide all types of hydraulic fittings, we accept custom and personalized manufacturing, every step is strictly controlled to ensure product quality, if you want to know more information, please feel free to contact us.

Your reliable Hose Clamps manufacturer

The hose clamp is a device that clamps onto the hose and is used to secure the hose to prevent leakage of fluid within the hose. Topa company can offer different types of hose clamps, and our hose clamps have a large number of benfits:

- Versatile

- Multiple material

- Top-quality

- Suitable price

- Easy to install and remove

- Strength

- Durable

Why choose us

Topa is a company that specializes in hydraulic parts, and we can provide all types of hydraulic parts to every interested customer. And we can also provide some other tools. For example, tube shrinkers, safety ropes, protective sleeves, industrial tubes, etc.

In addition to the high quality products, we also provide.

- Fast response

Our staff will reply to your inquiry as soon as possible and provide you with the appropriate information

2.Variety of choices

We have a wide range of accessories, if you need accessories, you can ask us.

3.Customized service

If you have some special parts needs, you can provide the corresponding information, we can arrange custom service for you.

4.Free samples

If the inventory allows, we can provide you with free samples, but you need to bear the corresponding shipping cost.

Application

Hose clamps are very versatile and they can usually be used in medium or low pressure environments.Hose clamps can be used in automotive, agricultural, and home repair applications.

Industry

The special material hose clamps can be used well in some specific environments without damage due to chemicals. The hose clamps can be used in the transport pipeline of the factory.

Agriculture

Hose clamps are mainly used to fix hoses or tubes so that they form a tight connection. Hose clamps can be used in agricultural machinery or pipelines to prevent fluid leakage.

Marine

Hose clamps allow hoses or tubes to form tight connections. Hose clamps can be used in marine transportation pipelines or other tools to prevent fluid leakage and corrosion.

Hose clamps quality control

For each Topa product, multiple checks such as manufacturing monitoring, quality testing and packaging inspection are carried out to ensure the quality and level of the product.

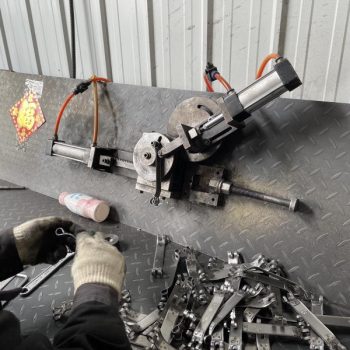

Hose clamps manufacturing process

Hose clamps go through a complex manufacturing process from raw material to molding, which is roughly divided into four steps: stamping, spot welding, encircling and assembly.

Stamping

In this initial stage, the metal material is stamped into specific shapes or patterns using a stamping machine.

Spot Welding

Spot welding is employed to join different pieces of metal together. This is crucial for adding components like screws or fasteners to the main body of the clamp.

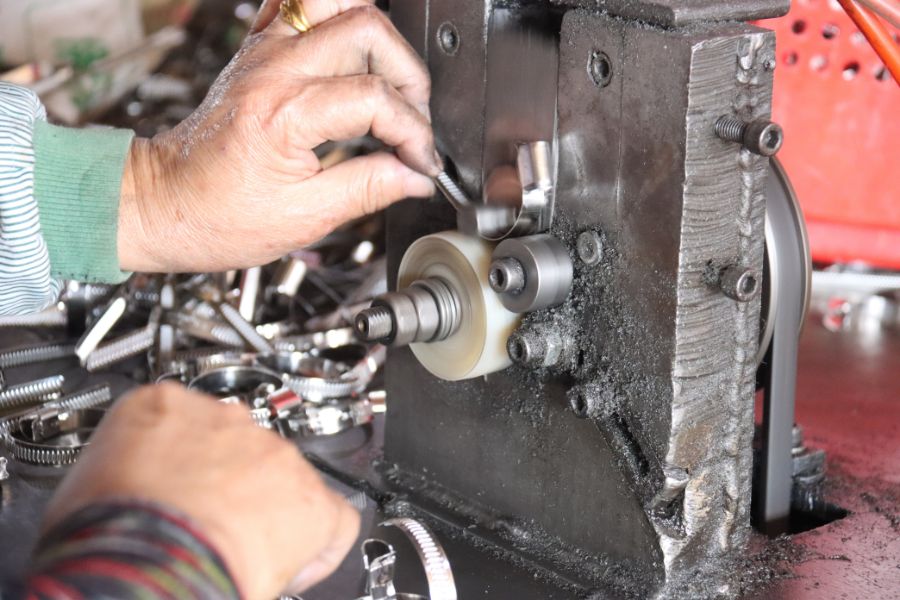

Encircling

The metal is then encircled to form a complete loop, finalizing the basic structure of the hose clamp. This ensures that it can securely encircle hoses or pipes.

Assembly

Finally, all the components are assembled together to complete the hose clamp. This includes adding any additional features like tightening mechanisms

Stamping process video

This video shows the stamping step in the hose clamp manufacturing process. This sets the foundational structure for the hose clamp.

Encircling process video

This video shows the encircling step in the hose clamp manufacturing process. This step gives the hose clamp the shape of a circle.

FAQ

what is a hose clamp?

The hose clamp is a device that clamps onto the hose and is used to secure the hose to prevent leakage of fluid within the hose.

What are the types of hose clamps?

There are many types of hose clamps, the common types are as follows: ear clamps, spring hose clamps, worm type hose clamps, single and double line clamps, quick release clamps, hole clamps with inclined housing, spiral clamps, etc.

how does hose clamp work?

After being fixed to a hose or other object that needs to be fixed, the hose clamp will fit snugly into the joint of the object, forming a seal and stopping the fluid from leaking.

What are the benefits of hose clamps?

Hose clamps, when properly installed, create a tight seal and prevent fluid leakage. The hose clamps are strong and durable, very easy and convenient to operate, and versatile.

How to stop hose clamp leak?

First, choose the correct size of the hose clamp, to ensure that the size of the clamp can be perfectly adapted to the hose; second, select a high-quality hose clamp, do not be greedy for cheap choice of inferior clamps, high-quality clamps can extend the use of years; third, do not over-tighten the clamp, too tight may cause the clamp broken or too much pressure.

How to install a hose clamp?

First, choose the right size before installing the hose clamps; next, unscrew the nuts of the hose clamps and place them in the right position; then, using the right tool, tighten the nuts, but do not overtighten them, otherwise it will be counterproductive.

What are the materials of hose clamp?

The most common materials used for hose clamps are stainless steel and carbon steel. Other materials, such as titanium, plastic, and galvanized steel are also suitable for hose clamps.

What are the usages of hose clamps?

Hose clamps are very versatile and they can usually be used in medium or low pressure environments. In high pressure environments, it is important to choose clamps that are resistant to high pressure. Hose clamps can be used in automotive, agricultural, and home repair applications.

Are hose clamps reusable?

Under normal use, the pipe clamps are reusable. However, if the pipe clamps are rusted, loose, or broken, it is better to replace them with new ones to prevent other losses.

Do hose clamps rust?

Whether the hose clamp will rust depends on the material of the hose clamp, stainless steel hose clamp generally will not rust, while other materials of metal hose clamp may rust.