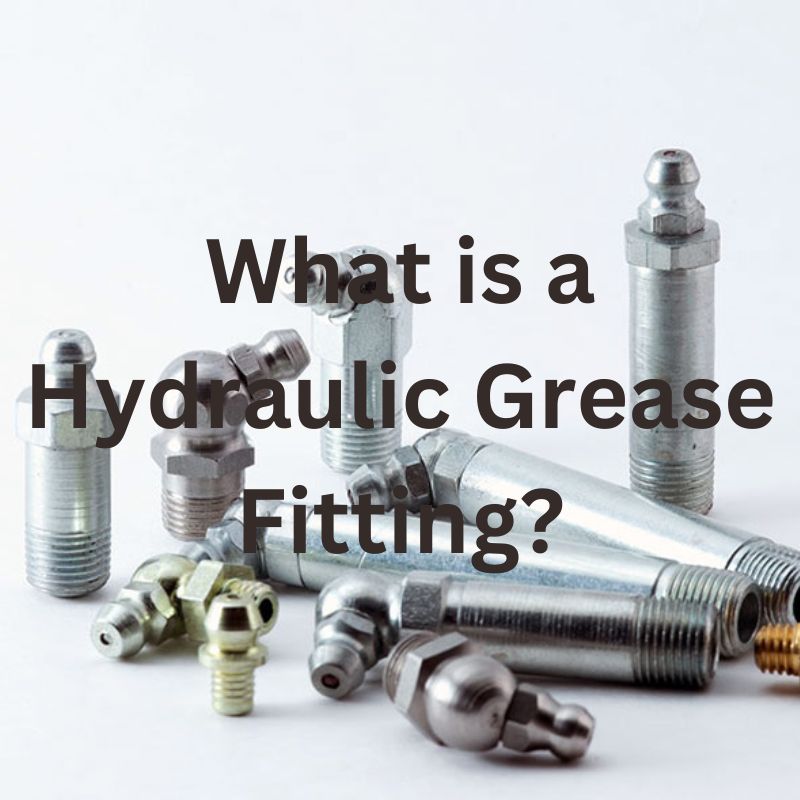

What is a Hydraulic Grease Fitting?

Understanding Hydraulic Grease Fittings

Definition and Function

Hydraulic grease fittings, commonly known as grease nipples or zerks, are specialized components designed for the precise delivery of lubricant under pressure to critical parts of machinery. These fittings serve a vital function in machinery maintenance, allowing for the direct application of grease to bearings, joints, and other friction-prone areas. Their design ensures that lubricant is efficiently distributed, even under the challenging conditions often encountered in industrial and mechanical environments.

Historical Development

The concept and application of hydraulic grease fittings emerged in the early 20th century, representing a pivotal innovation in machinery maintenance techniques. Prior to their invention, lubrication methods were less efficient and more time-consuming, often requiring machinery to be partially disassembled for proper lubrication. The introduction of grease fittings revolutionized this process by providing a quick, clean, and effective way to maintain lubrication levels without the need for disassembly, significantly reducing downtime and improving the reliability of machinery.

Role in Maintenance

Since their introduction, hydraulic grease fittings have evolved to become a cornerstone of maintenance practices across various industries. Their simplicity and effectiveness in delivering lubricant precisely where it is needed have made them indispensable tools in the maintenance of complex machinery. By ensuring that all moving parts are adequately lubricated, these fittings play a crucial role in minimizing wear and tear, preventing mechanical failures, and extending the operational lifespan of equipment. The widespread adoption of grease fittings has led to improvements in maintenance efficiency, equipment performance, and overall productivity, solidifying their status as essential components in modern machinery maintenance protocols.

Types of Hydraulic Grease Fittings

Hydraulic grease fittings are categorized based on their design and intended application, each type suited to specific machinery configurations and accessibility requirements. Here’s a closer look at the common types of hydraulic grease fittings and their unique characteristics.

Straight Fittings

Straight grease fittings are the most basic and widely used type. They are designed for direct access points where the lubricant path is straightforward, with no obstructions. Straight fittings are typically used in areas of machinery where the grease gun can be easily aligned with the fitting for a direct application of lubricant. Their simplicity makes them a popular choice for standard maintenance tasks.

Angled Fittings

Angled grease fittings are designed to provide lubrication in hard-to-reach areas where direct access is not possible. These fittings are available in various angles (such as 45 degrees and 90 degrees) to accommodate different installation scenarios. Angled fittings are ideal for tight spaces or awkward angles, where a straight fitting would not be practical. They ensure that lubricant can be applied efficiently, even in the most challenging areas of machinery.

Button-Head Fittings

Button-head grease fittings feature a larger surface area on the head, making them suitable for applications requiring a significant amount of lubricant to be applied quickly. These fittings are often used in high-load bearing areas where adequate lubrication is critical to maintaining smooth operation. Button-head fittings provide an easy target for the grease gun, ensuring a secure connection for the delivery of lubricant.

The Mechanics of Hydraulic Grease Fittings

The functionality of hydraulic grease fittings is rooted in the principle of delivering lubricant under pressure. This mechanism ensures that grease is efficiently forced into the machinery’s lubrication points, such as bearings and joints, to maintain smooth operation and minimize wear. Understanding the mechanics behind hydraulic grease fittings is essential for optimizing the lubrication process.

Principle of Pressure-Driven Lubrication

Hydraulic grease fittings operate by creating a sealed connection with a grease gun, which then pumps grease into the fitting under pressure. This pressure is crucial for overcoming the resistance present within the machinery’s lubrication channels. It ensures that the lubricant reaches all necessary areas, even those that are tightly sealed or difficult to access due to their design or accumulated debris.

Role of the Grease Gun

The grease gun plays a pivotal role in the lubrication process. It is the tool that applies the necessary pressure to the grease, propelling it through the fitting and into the machinery’s lubrication points. Grease guns come in various types, including manual, pneumatic, and electric, each capable of delivering different pressure levels to suit specific requirements of the hydraulic grease fittings and the machinery being lubricated.

Overcoming Resistance

The effectiveness of lubrication depends on the grease’s ability to overcome the resistance encountered within the lubrication system. This resistance can come from the tightness of the components, the viscosity of the grease, or the presence of old, hardened lubricant. The pressure applied by the grease gun must be sufficient to surpass these obstacles, ensuring that fresh lubricant is distributed evenly and effectively throughout the component.

Achieving Efficient Lubrication

Efficient lubrication is achieved when the grease is delivered in the right quantity and at the right pressure to maintain optimal performance of the machinery. Too little pressure may result in inadequate lubrication, while too much pressure can damage the grease fitting or the lubrication points. The goal is to achieve a balance where the lubricant is fully dispensed throughout the necessary areas without causing harm to the machinery.

Installing Hydraulic Grease Fittings

Installing hydraulic grease fittings correctly is crucial for the efficient operation of the lubrication system and the longevity of machinery components. Here is a step-by-step guide to ensure proper installation, along with tips to avoid common mistakes.

Preparation

Identify Lubrication Points: Before installation, identify all the points on the machinery that require lubrication. This helps in determining the number and type of grease fittings needed.

Clean the Area: Ensure that the area around the installation points is clean and free from debris. Any dirt or grime can enter the lubrication system and cause blockages or wear.

Tool Selection

Choose the Right Tools: You will need a drill and tap set if you’re creating new threads for the fittings, or a wrench for tightening fittings into pre-threaded holes. Ensure the tools match the size and thread type of the grease fittings.

Select the Appropriate Fittings: Based on the machinery’s requirements, select the type (straight, angled, button-head) and size of the grease fittings.

Installation Process

Create or Clean Threads: If installing a new fitting, drill and tap the hole to the correct size. For replacement, clean the threads in the existing hole to ensure a smooth installation.

Apply Thread Sealant (if necessary): For fittings that require sealant, apply a small amount to the threads to prevent leaks.

Install the Fitting: Hand-tighten the grease fitting into the hole, then use a wrench to secure it. Avoid over-tightening, as this can strip the threads or damage the fitting.

Check for Proper Alignment: Ensure the fitting is aligned correctly, especially angled fittings, to facilitate easy access for the grease gun.

Common Pitfalls to Avoid

Over-Tightening: This is one of the most common mistakes. It can cause the threads on the grease fitting or in the machinery to strip, leading to leaks or difficulty in future removal.

Incorrect Fitting Type: Using the wrong type of fitting for the application can hinder the lubrication process. Always match the fitting type to the specific lubrication needs of the point.

Ignoring Cleanliness: Failing to clean the installation area and the threads properly can introduce contaminants into the lubrication system, potentially causing blockages or accelerated wear.

Final Steps

After installation, perform a test lubrication to ensure that grease flows freely through the new fittings. Check for leaks around the fittings and correct any issues immediately. Proper installation not only ensures efficient lubrication but also prolongs the life of both the fittings and the machinery they serve. By following these guidelines and avoiding common mistakes, you can ensure a successful and reliable setup of hydraulic grease fittings.

Maintenance and Troubleshooting

Maintaining hydraulic grease fittings is crucial for the longevity and proper functioning of machinery. Regular maintenance helps prevent common issues like clogs and leaks. This section offers guidance on maintaining these fittings and troubleshooting common problems.

Routine Maintenance

Regular Inspections: Schedule periodic inspections of grease fittings as part of routine maintenance. Look for signs of wear, damage, or corrosion.

Cleaning: Before lubricating, clean the fitting’s exterior to prevent dirt and debris from entering the lubrication system. Use a clean cloth or a suitable cleaning agent.

Proper Lubrication: Regularly lubricate the fittings according to the machinery’s lubrication schedule. Ensure that the correct type of grease is used for each fitting.

Replacement Strategies

Identify Worn Out Fittings: Over time, fittings can become worn or damaged and may need replacement. Signs include difficulty in attaching the grease gun, leakage around the fitting, or visible damage.

Use the Correct Replacement: Ensure the replacement fitting matches the size, thread, and type of the old one. Using incorrect fittings can lead to leaks or inadequate lubrication.

Proper Installation: Follow the guidelines for proper installation when replacing a fitting to ensure it functions correctly.

Troubleshooting Common Issues

Clogged Fittings: Clogs can occur due to hardened grease or debris. Try cleaning the fitting with a grease fitting cleaner tool. If the clog persists, the fitting may need to be replaced.

Leaks: If grease is leaking from around the fitting, it could be due to overfilling, damaged threads, or a poor seal. Tighten the fitting or replace it if necessary. Ensure the use of thread sealant if applicable.

Ineffective Lubrication: If lubrication isn’t reaching the intended parts, it could be due to a blockage in the lubrication path, incorrect fitting type, or issues with the grease gun. Check for blockages and ensure the correct fitting type and grease gun operation.

Ensuring Continuous Operation

By adhering to a regular maintenance schedule and promptly addressing any issues, you can ensure the continuous and effective operation of hydraulic grease fittings. Regular maintenance not only extends the life of the fittings but also contributes to the overall health and longevity of the machinery. Troubleshooting common issues quickly and effectively minimizes downtime and maintains the efficiency of your equipment.

The Importance of Choosing the Right Grease

Selecting the appropriate grease is a critical aspect of ensuring the optimal performance of hydraulic grease fittings and the machinery they lubricate. Different types of grease vary in their properties and suitability for specific applications. Understanding these variations and the factors influencing grease selection is essential.

Understanding Grease Types

Multi-Purpose Grease: This is a general-use grease suitable for a wide range of applications. It’s a good choice for standard machinery and common lubrication points.

High-Temperature Grease: Designed to withstand high temperatures, this grease is ideal for machinery that operates under extreme heat conditions.

Low-Temperature Grease: This type remains fluid and effective in cold environments, making it suitable for machinery used in cold climates.

Water-Resistant Grease: Useful in wet or humid conditions, this grease type maintains its consistency and lubricating properties even when exposed to water.

Food-Grade Grease: For machinery used in the food processing industry, food-grade grease is essential as it’s safe for incidental food contact.

Factors Influencing Grease Selection

Viscosity: The viscosity of grease should match the operating speed and load of the machinery. Higher viscosity grease may be needed for high-load or slow-moving applications, while lower viscosity is suitable for high-speed or lighter-load applications.

Temperature Range: The operating temperature range of the machinery dictates the type of grease needed. High-temperature grease is necessary for machinery that generates a lot of heat, while low-temperature grease is required for equipment used in colder environments.

Environment: Consider the environment in which the machinery operates. If exposed to water, a water-resistant grease is advisable. In dusty or dirty environments, a grease with good sealing properties is beneficial.

Compatibility: Ensure that the new grease is compatible with any residual old grease. Mixing incompatible greases can lead to reduced lubricating properties and potential damage.

Impact on Performance and Longevity

The right grease choice directly affects the performance and longevity of both the hydraulic grease fittings and the machinery. Suitable grease ensures proper lubrication, reduces wear and tear, and prevents overheating or freezing of moving parts. It also extends the lifespan of the fittings by maintaining their sealing and delivery efficiency. Regular review and adjustment of grease selection based on changing conditions or machinery requirements can lead to significant improvements in machinery operation and maintenance efficiency.

Conclusion

In conclusion, the effective use and maintenance of hydraulic grease fittings are fundamental to the longevity and optimal performance of machinery. From understanding the variety and functionality of grease fittings to the meticulous process of installation and maintenance, each aspect plays a crucial role in the overall health of mechanical systems.Ultimately, hydraulic grease fittings, though small in size, are significant in impact. Their correct usage, coupled with informed maintenance decisions, forms the backbone of efficient machinery operation in various industrial and mechanical applications. The knowledge and practices outlined in this guide should empower users to manage and maintain their hydraulic grease fittings effectively, ensuring that their machinery continues to operate smoothly and reliably.